Ionic liquid-modified loaded carbine-palladium catalyst and application thereof in acetylene hydrogenation reaction

An ionic liquid, palladium catalyst technology, applied in catalytic reactions, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of low ethylene selectivity and achieve good ethylene selectivity, The effect of high acetylene conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

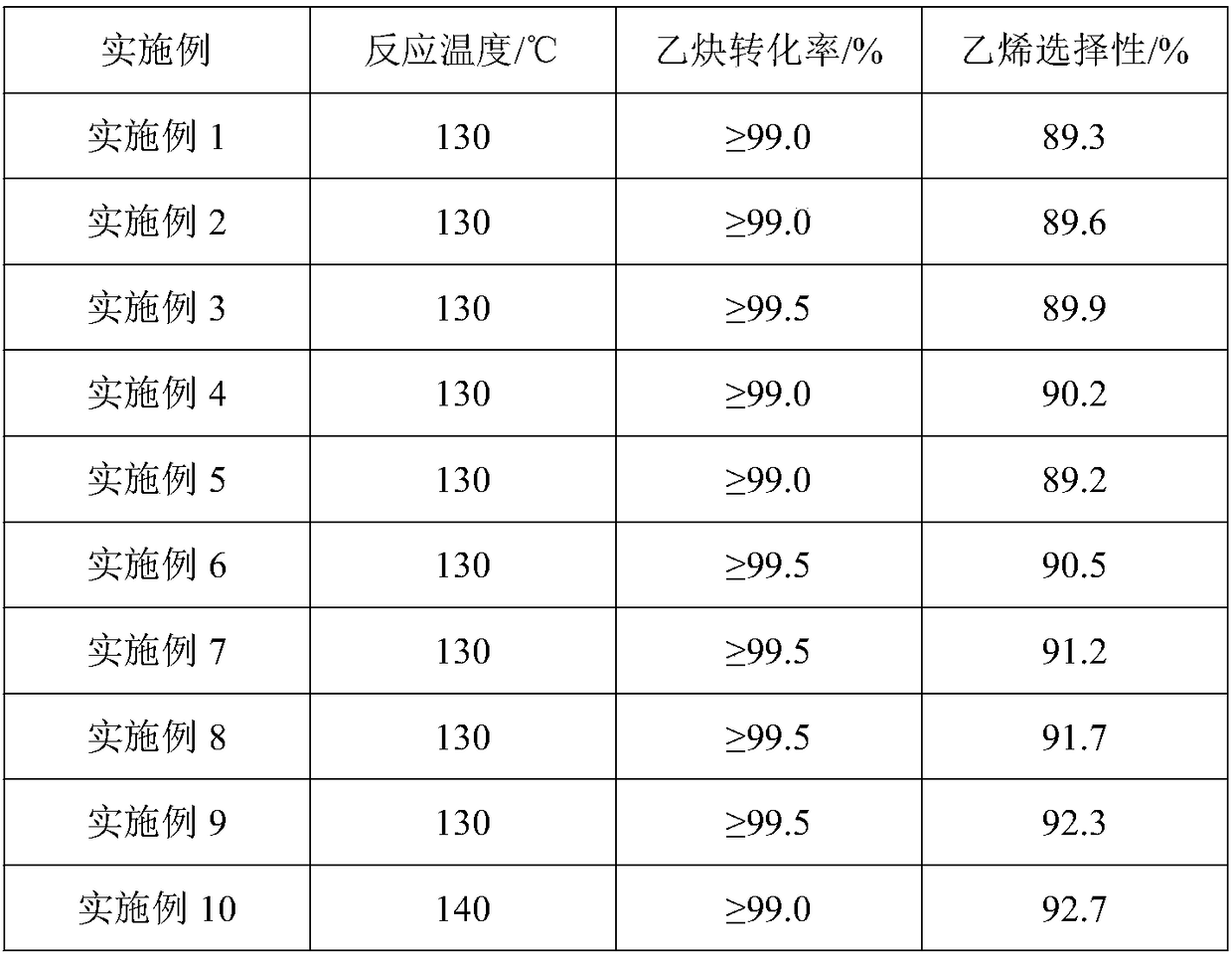

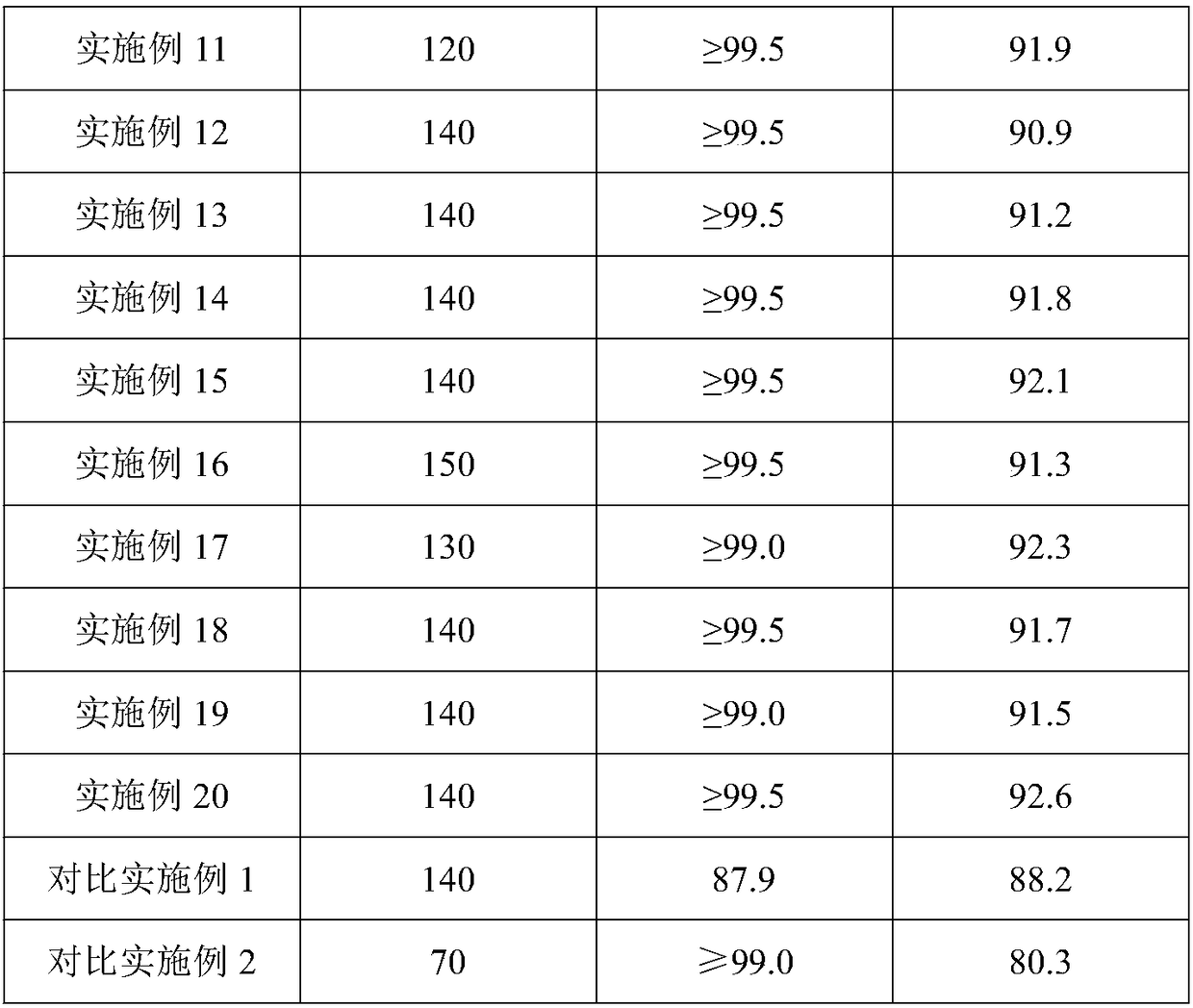

Examples

Embodiment 1

[0028] Dissolve 0.08g (0.5mmol) of 1-propyl-3 methylimidazole chloride in 2mL of dimethylsulfoxide (DMSO), add 0.041g (0.5mmol) of anhydrous sodium acetate, and keep stirring at 90°C for 1h After the solid was completely dissolved, 0.22 g (1.0 mmol) of palladium acetate was added to the clear solution as a palladium precursor, and stirred and heated at 120° C. for 4 hours to obtain a carbene-palladium solution. Transfer the obtained solution to a 10 mL volumetric flask, add DMSO to the corresponding scale to obtain a carbene-palladium impregnation liquid with a concentration of 0.001 g / mL.

[0029] Using the impregnation method, according to the requirement that the palladium loading is 0.1wt%, and the ionic liquid loading is 20wt%, pipette the metered carbene-palladium impregnation solution and mix with a certain amount of 1-propyl-3 methylimidazolium chloride ionic liquid, Then add a certain amount of DMSO in the impregnation solution, and then evenly put the alumina carrier...

Embodiment 2

[0031] Dissolve 0.16g (1.0mmol) of 1-propyl-3 methylimidazole chloride in 2mL of dimethyl sulfoxide (DMSO), add 0.082g (1.0mmol) of anhydrous sodium acetate, and keep stirring at 90°C for 1h After the solid was completely dissolved, 0.22 g (1.0 mmol) of palladium acetate was added to the clear solution as a palladium precursor, and stirred and heated at 120° C. for 4 hours to obtain a carbene-palladium solution. Transfer the obtained solution to a 10 mL volumetric flask, add DMSO to the corresponding scale to obtain a carbene-palladium impregnation liquid with a concentration of 0.001 g / mL.

[0032] Using the impregnation method, pipette the measured carbene-palladium impregnation solution and mix it with a certain amount of 1-propyl-3 methylimidazolium chloride ionic liquid, then add a certain amount of DMSO into the impregnation solution, and then evenly put the alumina carrier (The specific surface area is 384m 2 / g) into the impregnating solution and sonicate. The wet su...

Embodiment 3

[0034] Dissolve 0.32g (2.0mmol) of 1-propyl-3 methylimidazole chloride in 2mL of dimethyl sulfoxide (DMSO), add 0.16g (2.0mmol) of anhydrous sodium acetate, and keep stirring at 90°C for 1h After the solid was completely dissolved, 0.22 g (1.0 mmol) of palladium acetate was added to the clear solution as a palladium precursor, and stirred and heated at 120° C. for 4 hours to obtain a carbene-palladium solution. Transfer the obtained solution to a 10 mL volumetric flask, add DMSO to the corresponding scale to obtain a carbene-palladium impregnation liquid with a concentration of 0.001 g / mL.

[0035] Using the impregnation method, pipette the measured carbene-palladium impregnation solution and mix it with a certain amount of 1-propyl-3 methylimidazolium chloride ionic liquid, then add a certain amount of DMSO into the impregnation solution, and then evenly put the alumina carrier (The specific surface area is 384m 2 / g) into the impregnating solution and sonicate. The wet sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com