Method for preparing enol by electrocatalytic selective hydrogenation of alkynol

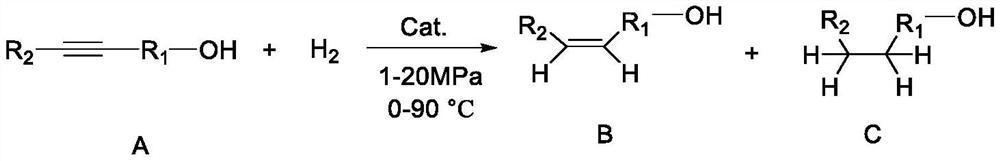

A selectivity and hydrogen preparation technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of expensive noble metal catalysts, high reaction temperature, long reaction time, etc., to avoid excessive hydrogenation, reduce energy consumption, reduce and potential dangerous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (1) Preparation of Ag nanoparticle catalyst slurry: Disperse 10 mg of Ag nanoparticle catalyst powder in 6 mL of isopropanol, then add 50 μL of Nafion solution (5%), stir and ultrasonically disperse for 90 min.

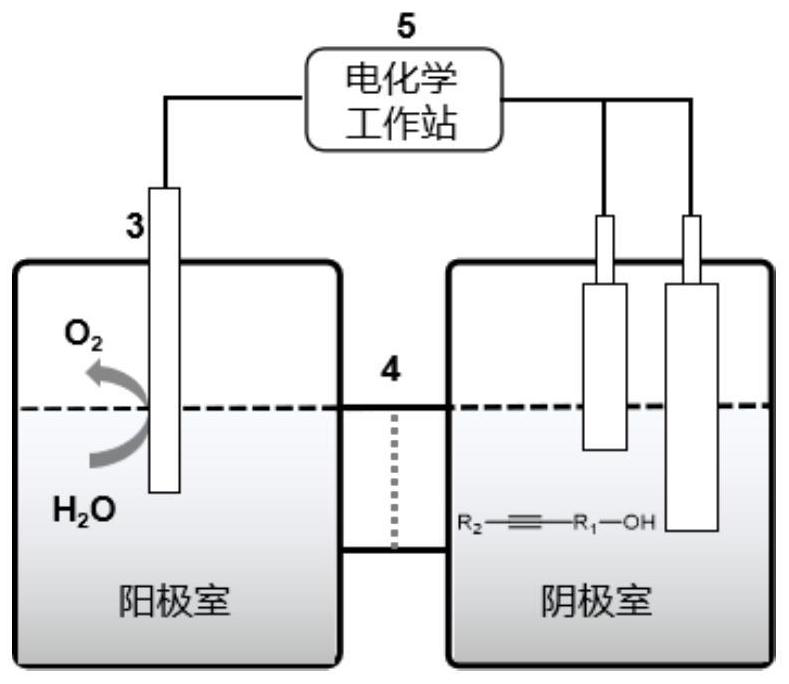

[0068] (2) Spray the Ag nanoparticle slurry evenly on both sides of the conductive substrate as the cathode of the electrolytic cell, Hg / HgO as the reference electrode of the electrolytic cell, insert the working electrode and the reference electrode into the cathode chamber and fix the distance; The anode of the pool is inserted into the anode chamber and parallel to the exchange membrane; both the catholyte and the anolyte are 1M KOH solution, separated by an anion exchange membrane. Add 5 mL of the reactant 2-methyl-3-butyn-2-ol to the catholyte and expedite mass transfer through a stirrer.

[0069] (3) A split H-type electrolytic cell with a three-electrode system is used, and the electrochemical performance test is performed through an electrochemical work...

Embodiment 2

[0071] (1) Preparation of Cu nanoparticle catalyst slurry: Disperse 10 mg of Cu nanoparticle catalyst powder in 6 mL of isopropanol, then add 50 μL of Nafion solution (5%), stir and ultrasonically disperse for 90 min.

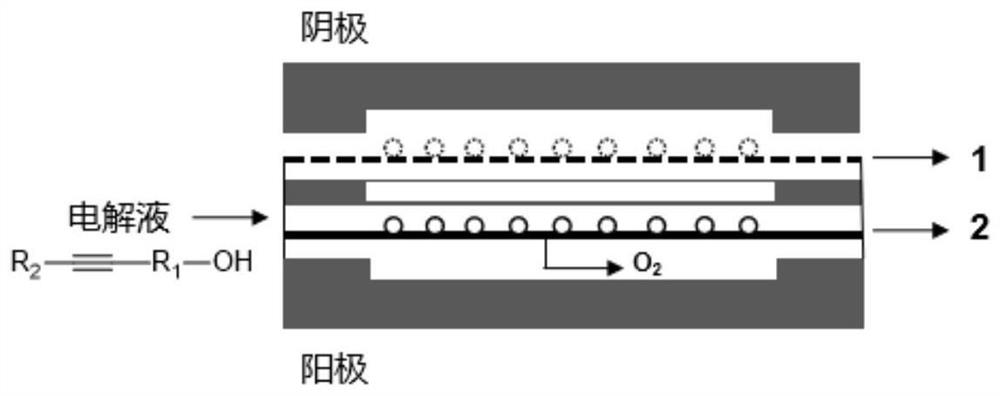

[0072] (2) Spray the Cu nanoparticle slurry evenly on the hydrophobic surface of the carbon paper as the cathode of the electrolytic cell, Hg / HgO as the reference electrode of the electrolytic cell, nickel foam as the anode of the electrolytic cell, and both the cathode and anode electrolytes are 1M KOH solution. separated by an anion exchange membrane. Add 5 mL of reactant 2-methyl-3-butyn-2-ol to the catholyte.

[0073] (3) A flow-type electrolytic cell with a three-electrode system is used, and the electrochemical performance test is carried out through an electrochemical workstation. The catalytic activity of the catalyst Cu nanoparticles was characterized by potentiostatic method. The reactant acetylenic alcohol was reacted for 1 hour, and the liquid phase ...

Embodiment 3

[0075] (1) Preparation of membrane electrode slurry: Disperse 10 mg of Cu nanoparticle catalyst powder in 6 mL of isopropanol, then add 50 μL of Nafion solution (5%), stir and ultrasonically disperse for 90 min.

[0076] (2) The Cu nanoparticle slurry is evenly sprayed on the surface of the proton exchange membrane by a precision spraying device as the cathode of the electrolytic cell, and the nickel foam is used as the anode of the electrolytic cell. Both the catholyte and the anolyte are 1M KOH solution, and an exchange membrane is used between isolation. Add 5 mL of the reactant 1,4-butynediol to the catholyte.

[0077] (3) A flow-type electrolytic cell with a two-electrode system is used, and the electrochemical performance test is carried out through an electrochemical workstation. The catalytic activity of the catalyst Cu nanoparticle membrane electrode was characterized by potentiostatic method. The reactant acetylenic alcohol was reacted for 1 hour, and the liquid pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com