Composition for improving glossiness of polypropylene and reducing haze of polypropylene and application thereof

A composition and technology of polypropylene, applied in the field of compositions for improving the gloss of polypropylene and reducing the haze of polypropylene, and its application field, which can solve problems such as difficulty in improving gloss, reducing haze, and difficulty in lowering processing temperature , to achieve the effect of improving gloss, reducing haze, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

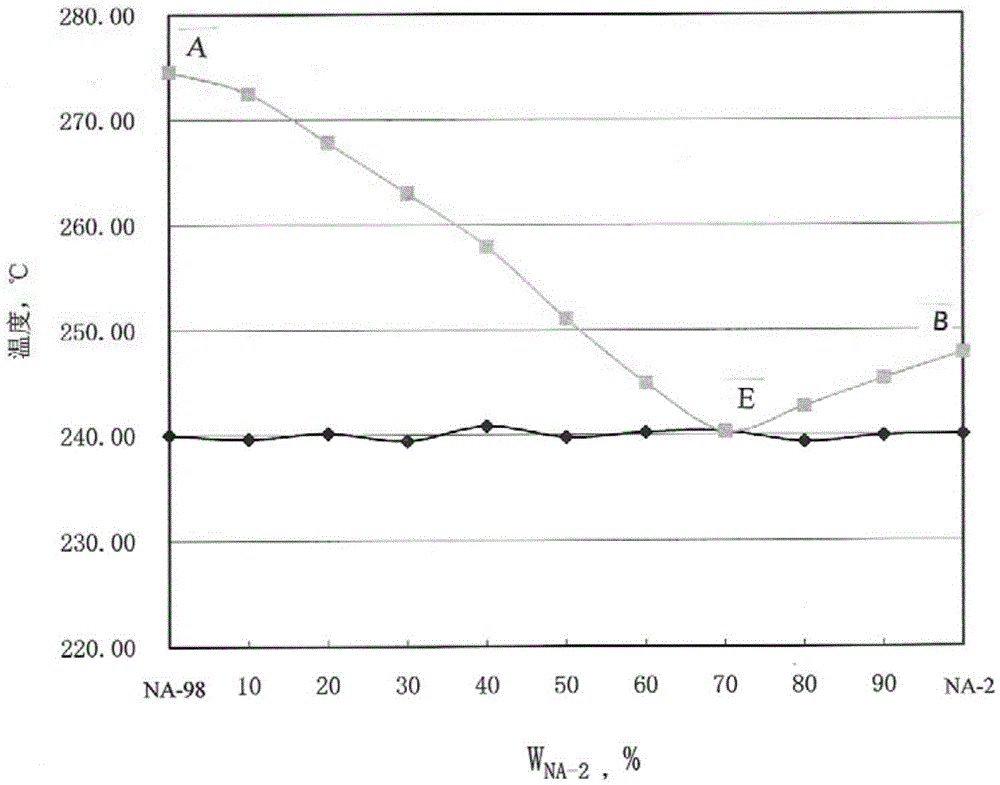

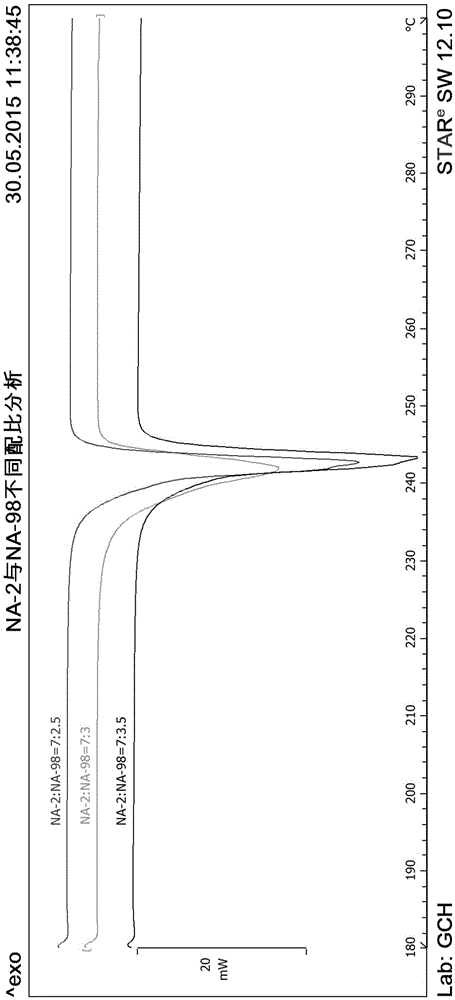

[0036] Example 1 Survey and draw the binary solid-liquid equilibrium phase diagram of the NA-2+NA-98 composition, and determine the eutectic temperature and composition of the NA-2+NA-98 composition.

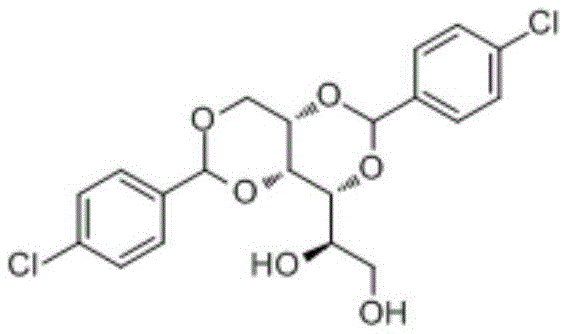

[0037] Determination of 1,3:2,4-bis-O-(p-chlorobenzylidene)-D-sorbitol (NA-2) and 1,3:2,4-bis(3,4- The melting curves of dimethylbenzylidene)-D-sorbitol (NA-98) and NA-2 and NA-98 in different proportion compositions can be drawn according to the principle of phase equilibrium thermodynamics NA-2+NA- 98 binary composition solid-liquid equilibrium phase figure 1 . Point E in the binary phase diagram is the eutectic point of the NA-2+NA-98 binary composition, the eutectic temperature is 240.29°C, and the composition of the binary composition is W NA-2 70%, that is, the weight ratio of NA-2 to NA-98 is 7:3.

[0038] The specific ratio of NA-2 and NA-98 and their melting peak temperature data are shown in Table 1.

[0039] Table 1NA-2 and NA-98 composition melting peak temperatu...

Embodiment 2

[0045] Embodiment 2 nucleating agent composition prepares polymkeric substance

[0046] 0.2% of the composition was added to the polymer base material. The ratio of NA-2 and NA-98 in the composition was mixed according to the composition number, and the haze of the polymer was measured at different temperatures. For details, see Table 3 below. The base material used therein is random copolymerized polypropylene MI=25g / 10min.

[0047] Table 3 Haze of polymers prepared from NA-2 and NA-98 compositions under different processing temperatures

[0048]

[0049] NA-2 can reduce the haze of NA-98 at a processing temperature of 180-190°C, and the reduction of haze is very obvious. The temperature of composition 11 is the processing temperature of single NA-98. At 180°C, the haze It is 36.2, and it is 30.1 at the processing temperature of 190°C, and the composition added with NA-2 and NA-98, such as composition 1-9, composition 12-13, can be processed at 180°C and 190°C Reduce haz...

Embodiment 3

[0055] Example 3 Comparison of haze properties using polymers comprising NA-98 compositions

[0056] Add 0.2wt% composition in the polymer base material, the ratio of NA-2 and NA-98 in the composition, the ratio of NA-98 and 1,3:2,4-di-p-methylbenzylidene sorbitol (MDBS) Ratio, mix according to the ratio corresponding to the serial number of the composition, and measure the haze of the polymer at different temperatures. For details, see Table 5 below. The base material used therein is random copolymerized polypropylene MI=25g / 10min.

[0057] Table 5 Effect of different compositions on polymer haze properties at different processing temperatures

[0058]

[0059]

[0060] The composition of NA-2 and NA-98 has little effect on PP haze when processed at low temperature. However, if MDBS and NA-98 are mixed, it will be difficult to reduce the haze at low temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com