Automatic doffing device for rotary spindle pre-loosening ring spinning

An automatic doffing and ring spinning technology, applied in textiles and papermaking, etc., can solve problems such as high cost, large reaction force, vibration and noise, achieve low manufacturing and maintenance costs, improve the success rate of yarn drawing, reduce The effect of yarn power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

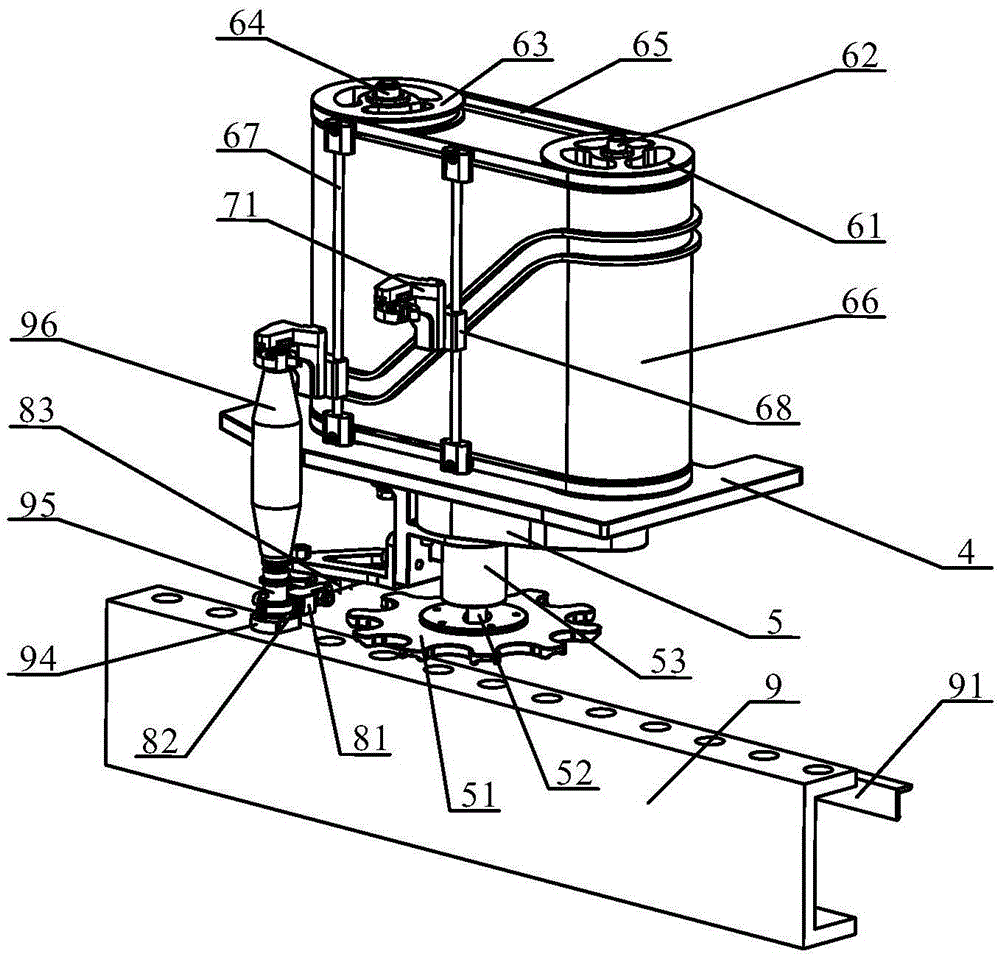

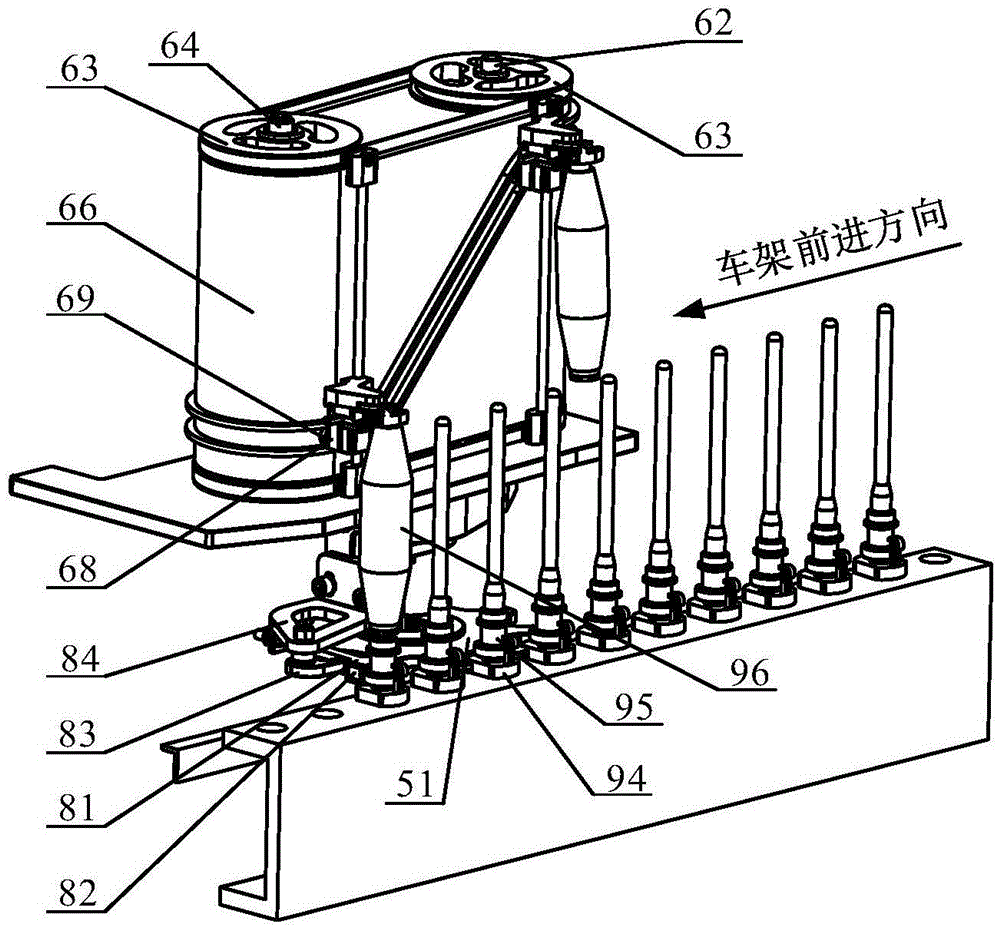

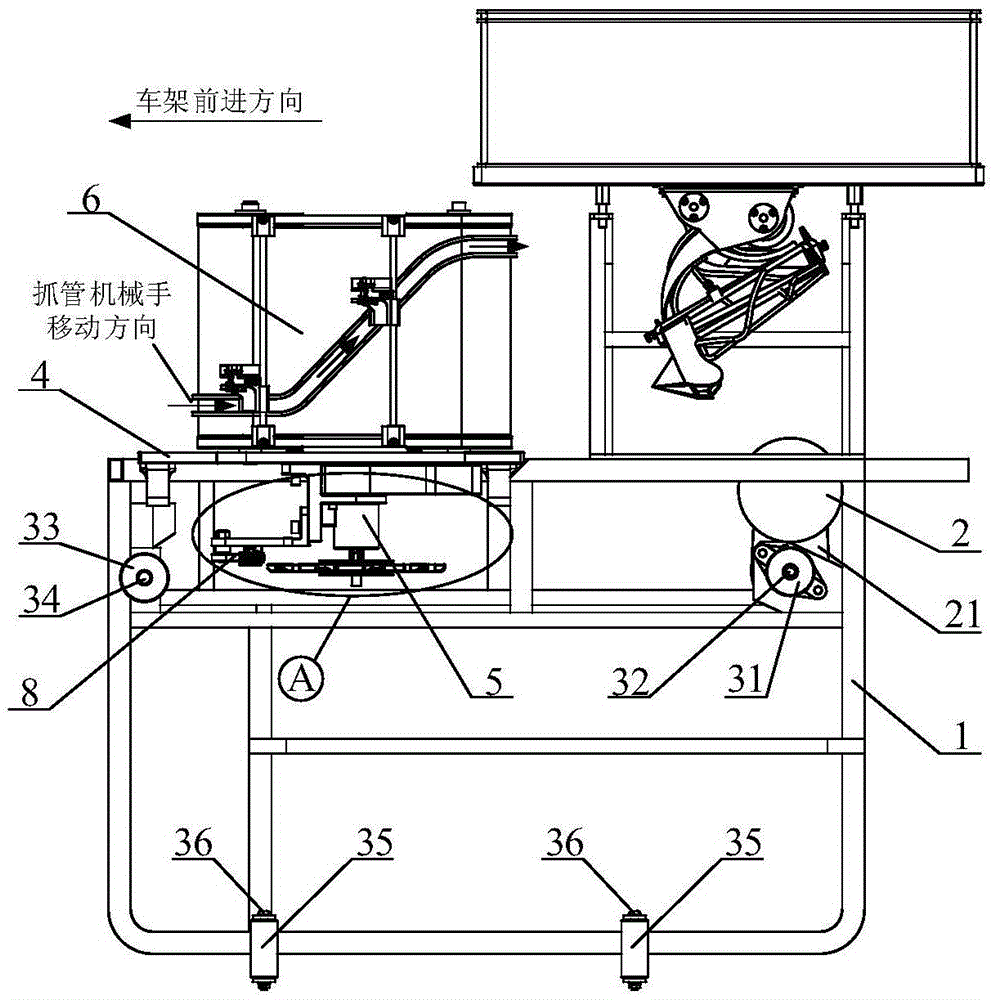

[0039] A kind of embodiment of the automatic doffing device of a kind of rotary spindle pre-loosening ring spinning designed by the present invention, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 Shown, comprise vehicle frame 1, motor 2, first transmission mechanism 21, driving guide wheel 31, driving guide wheel shaft 32, at least one driven guide wheel 33, at least one driven guide wheel shaft 34, at least one auxiliary wheel 35, at least one An auxiliary wheel shaft 36, a base 4, a walking mechanism 5, a doffing mechanism 6 and a pre-loosening mechanism 8; the motor 2 is fixedly installed on the vehicle frame 1, and the output shaft of the motor 2 is connected to the input The output end of the first transmission mechanism 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com