Petroleum coke particle combustion device

A combustion device, petroleum coke technology, applied in combustion equipment, solid fuel combustion, lighting and heating equipment, etc., can solve the problems of incomplete combustion of coal, increased emission of flue gas pollutants, increased combustion chamber volume, etc., to achieve investment Less, the principle is easy to understand the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention will be further described below in conjunction with the accompanying drawings.

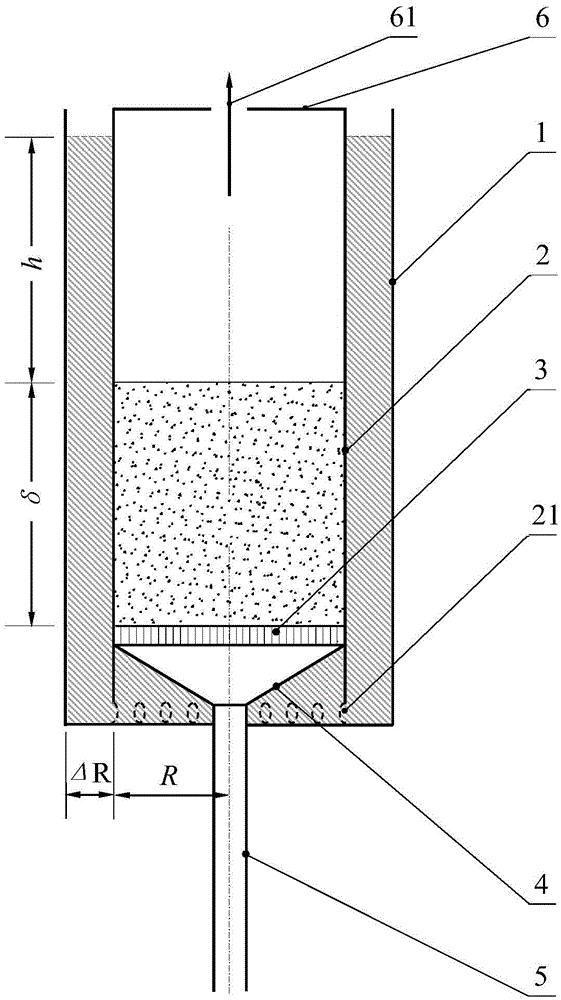

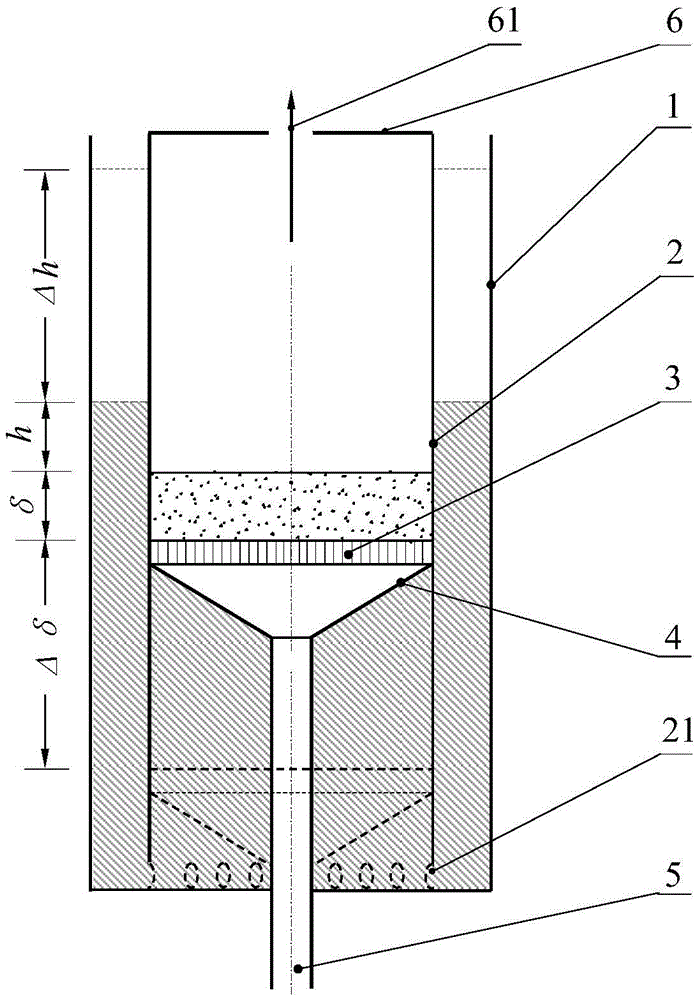

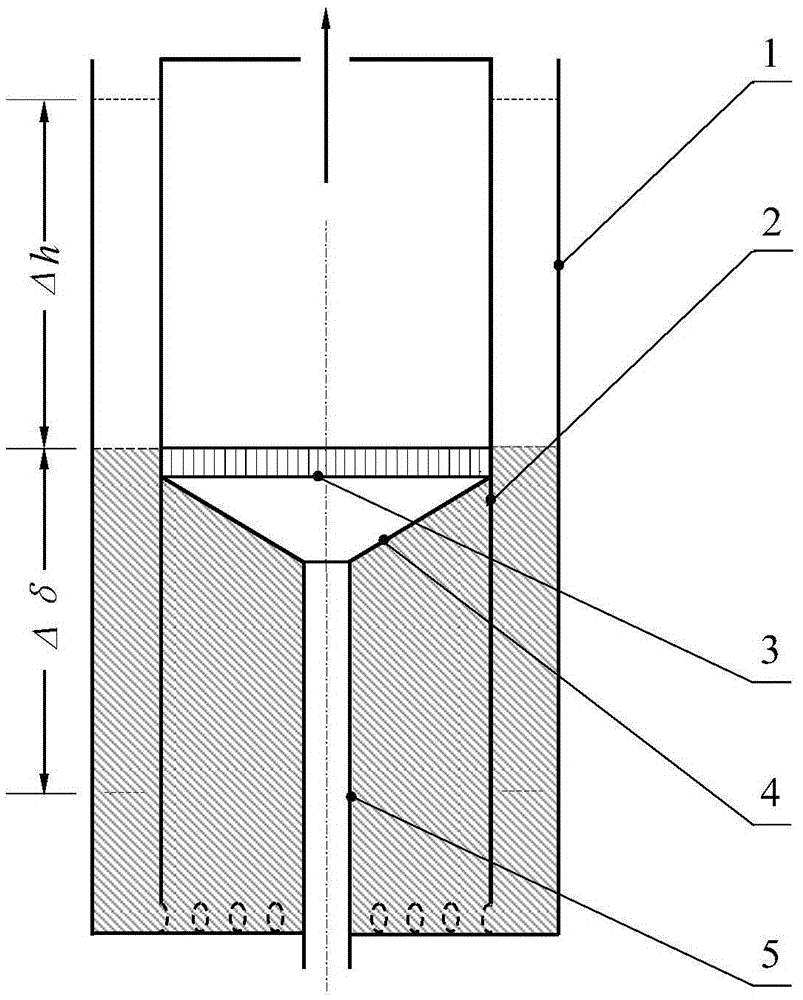

[0015] as attached figure 1 , attached figure 2 And attached image 3 As shown, the petroleum coke particle combustion device mainly includes a furnace shell 1, a furnace liner 2, a furnace bar 3, a pressure equalization chamber 4, an air inlet pipe 5 and a top cover 6. The top cover 6 is in the shape of a disc, and the center of the top cover 6 is provided with a round hole as the smoke outlet 61 . The intake pipe 5 is in the shape of a circular tube and arranged vertically. The pressure equalization chamber 4 is in the shape of an inverted circular platform, surrounded by a large circular bottom, a cylindrical side wall of the circular platform and a small circular bottom. The grate 3 is in the shape of a short cylinder and includes a horizontal top surface, a vertical side wall and a horizontal bottom surface. The furnace liner 2 is in the shape of a long cylinder an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com