Energy-saving environment-friendly circulating fluidized bed system

A circulating fluidized bed, energy saving and environmental protection technology, applied in the field of circulating fluidized bed systems, can solve the problems of poor material return, undisclosed high temperature flue gas, complex structure, etc., to eliminate sparks, ensure safety, and uniform fluidization reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

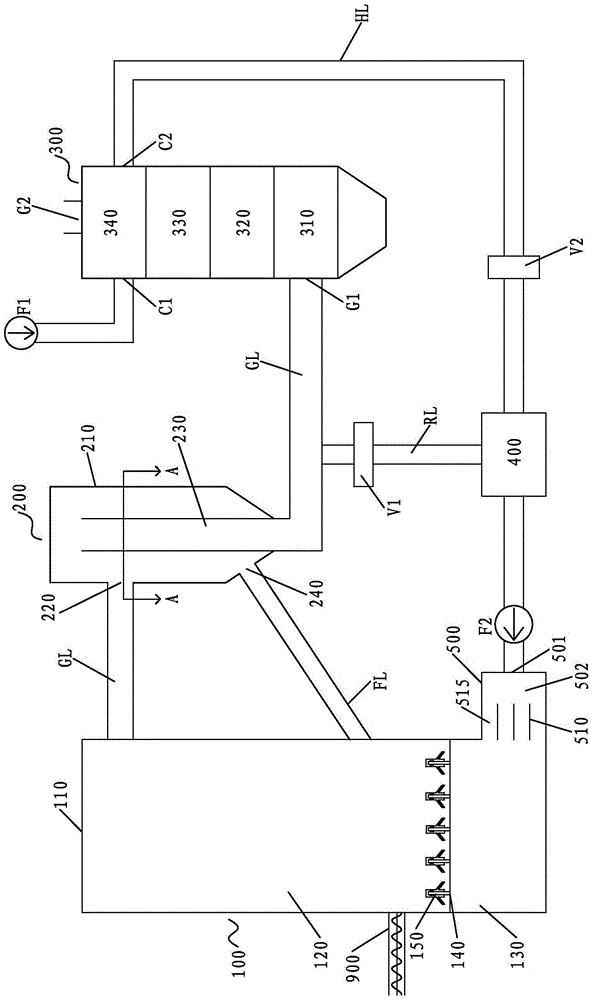

[0041] Please refer to figure 1 According to a non-limiting embodiment of the present invention, the energy-saving and environment-friendly circulating fluidized bed system includes: a fluidized bed 100, a flue gas separation device 200, a waste heat utilization device 300, and a flue gas pipeline GL.

[0042] Wherein, the fluidized bed 100 includes a fluidized bed body 110 and an air distribution plate 140 arranged inside the fluidized bed body 110, and the air distribution plate 140 divides the interior of the fluidized bed body 110 into a fluidized chamber 120 located above and a fluidized chamber 120 located below. The air chamber 130 is provided with several air caps 150 arranged on the air distribution plate 140 , so that the fluidizing air from the air chamber 130 can be sprayed into the fluidization chamber 120 by using the air caps 150 .

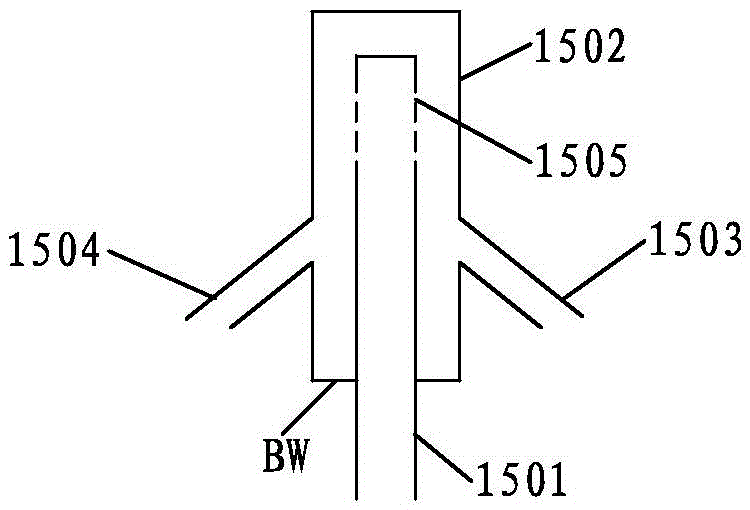

[0043] In this non-limiting embodiment, as figure 2 As shown, each air cap 150 includes an inner tube 1501, an outer tube 1502 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com