Novel heat exchanger core and distribution structure

A heat exchanger and core technology, which is used in geothermal energy, ocean thermal energy utilization, all equipment used in heat exchangers, solar energy, nuclear energy, and waste heat recovery fields, can solve the problem of shunt structure that has not been mentioned in public information, a surface exchange The application of the heater is slow, and there are no problems such as disclosing the shunt structure, so as to achieve the effect of compact core structure, easy configuration adjustment and strong shape adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention aims to provide a more compact primary surface heat exchanger and simultaneously provide a simple and feasible split flow structure.

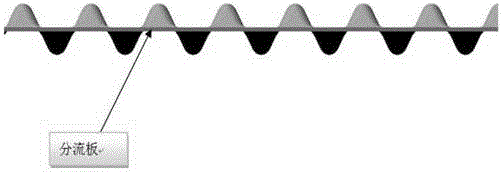

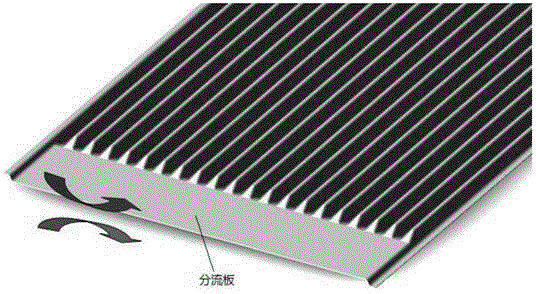

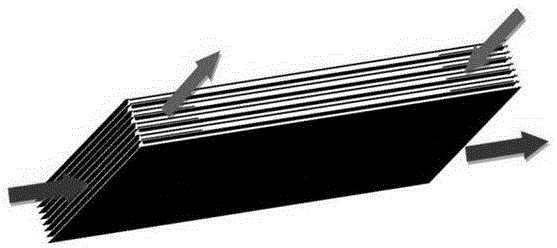

[0027]As we all know, primary surface heat exchangers are famous for their larger direct heat exchange area per unit volume, but primary surface heat exchangers with different structures have different difficulties in their split flow structures. The primary surface heat exchangers provided by this patent The core structure is more compact, and the heat exchange area per unit volume is larger, such as figure 1 and figure 2 As shown, each bundle of cold runners is completely surrounded by hot runners, and each bundle of hot runners is completely surrounded by cold runners, thus covering each other, and the core structure provided by this patent can divide the cold and hot flows into more flows This means that the heat transfer area per unit volume is larger, and all the heat transfer surfaces are primary surfaces, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com