Comprehensive test method of content of impurities in lithium ion battery nano conductive agent

A lithium-ion battery, nano-conductive technology, applied in the preparation of test samples, measuring devices, material analysis using wave/particle radiation, etc., can solve the problems of difficult dissolution of impurities, increase of batteries, small test results, etc., to achieve reduction Secondary pollution, guaranteed accuracy, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Weigh 40g of nano-conductive agent and dry it in a drying oven at 100°C for 8 hours to remove the solvent. After cooling, take it out and put it in a muffle furnace and burn it at 1000°C for 10 hours to remove graphite and weigh it. The weight is: 0.1987g ;

[0025] 2) Take the sample amount in step 1) and burn the nano-conductive agent at high temperature to leave a residue, carry out SEM-EDS (scanning electron microscope) energy spectrum analysis test, and qualitatively analyze the composition of impurity elements in the remaining residue;

[0026] The results show that the main components are Fe, Al, Co, Ni and Si.

[0027] The mass percentage of each component is Fe31.78%Al26.88%Co17.34%Ni1.5%Si7.68%

[0028] 3) According to the test results, there are many types of metal impurities, which are easy to form metal alloys that are not easy to dissolve, so choose aqua regia for dissolution, take 0.1900g and add 10ml of newly prepared aqua regia, and heat at 60-70°C ...

Embodiment 2

[0039] Weigh 20g of nano-conductive agent and dry it in a drying oven at 200°C for 6 hours to remove the solvent. After cooling, take it out and put it in a muffle furnace and burn it at 600°C for 10 hours to remove graphite and weigh it. The weight is: 0.0076g;

[0040] 2) Take the sample amount in step 1) and burn the nano-conductive agent at high temperature to leave a residue, carry out SEM-EDS (scanning electron microscope) energy spectrum analysis test, and qualitatively analyze the composition of impurity elements in the remaining residue;

[0041] Analyze the composition of impurity elements in the remaining components, mainly Fe and Al

[0042] The mass percentage of each component is Fe17.34%Al57.21%

[0043] 3) From the test results, the metal impurities are only Fe and Al which are easily soluble in dilute hydrochloric acid, which can be completely digested only with dilute hydrochloric acid. After adding 0.0066g of 5mol / L hydrochloric acid newly prepared to 10ml, ...

Embodiment 3

[0048] Embodiment 3 is similar to embodiment 2,

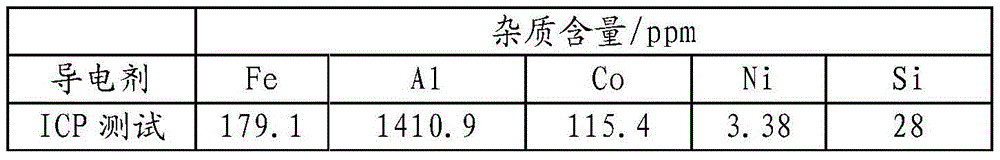

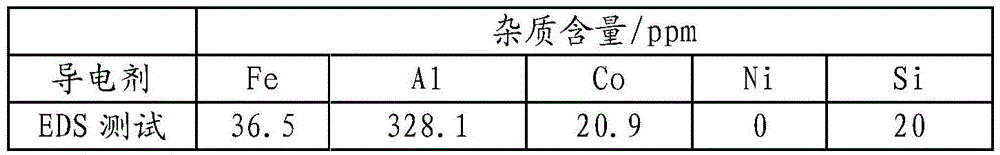

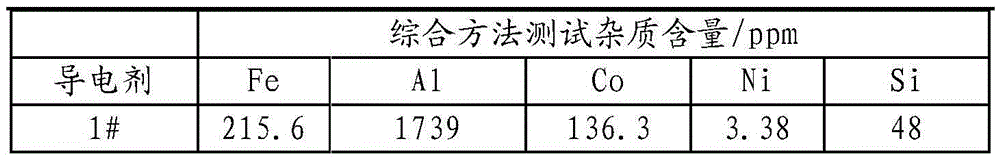

[0049] Take 1.500g of granular conductive agent powder (without solvent) C, and burn it at high temperature to remove graphite. EDS test shows that the main impurities are Fe and Al. The conductive agent powder can be completely digested with dilute hydrochloric acid. Use a volumetric flask for the digestion solution The final test result is the ICP test after the volume is set to 50ml.

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com