Nitride light emitting diode with AIN quantum dots and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as leakage and ESD deviation, and achieve the effects of increasing reverse voltage, reducing leakage, and preventing current from flowing through the dislocation line area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

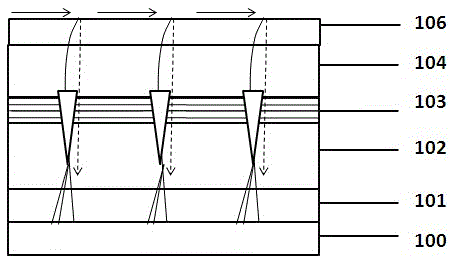

[0018] Such as figure 1 As shown, a conventional nitride light-emitting diode sequentially includes a substrate 100, a buffer layer 101, an N-type nitride 102, a multiple quantum well 103 with V-pits, a P-type nitride 104, and a P-type contact layer 106. A large number of dislocations caused by lattice mismatch and thermal mismatch will extend to the P-type layer to form a leakage channel, and electrons will tend to flow to the dislocation line with lower resistance, reducing the lateral expansion of the current, resulting in EDS deviation and leakage.

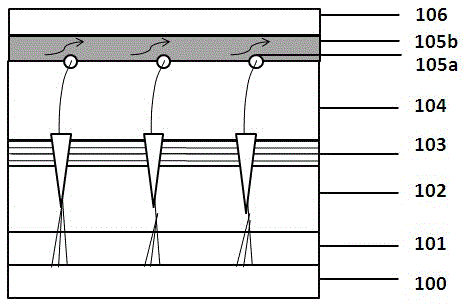

[0019] Such as figure 2 As shown, a light-emitting diode with AlN quantum dots proposed by the present invention sequentially includes a substrate 100, a buffer layer 101, an N-type nitride 102, a multiple quantum well 103 with V-pits, a P-type nitride 104, and no Mg-doped AlN quantum dots 105a, P-type nitride 105b with high Mg doping, and P-type contact layer 106, wherein there is no Mg inserted between the P-type nitride a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com