BOOST power conversion circuit and control method thereof

A technology for converting circuits and power, which is applied in the field of photovoltaic grid-connected inverter BOOST step-up power conversion circuit and its control, which can solve the problems of overvoltage breakdown of the second switching tube, overvoltage breakdown of diodes, and affecting circuit efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make those skilled in the art better understand the technical solutions provided by the embodiments of the present application, the working principle of the existing three-level Boost circuit is described below as an example.

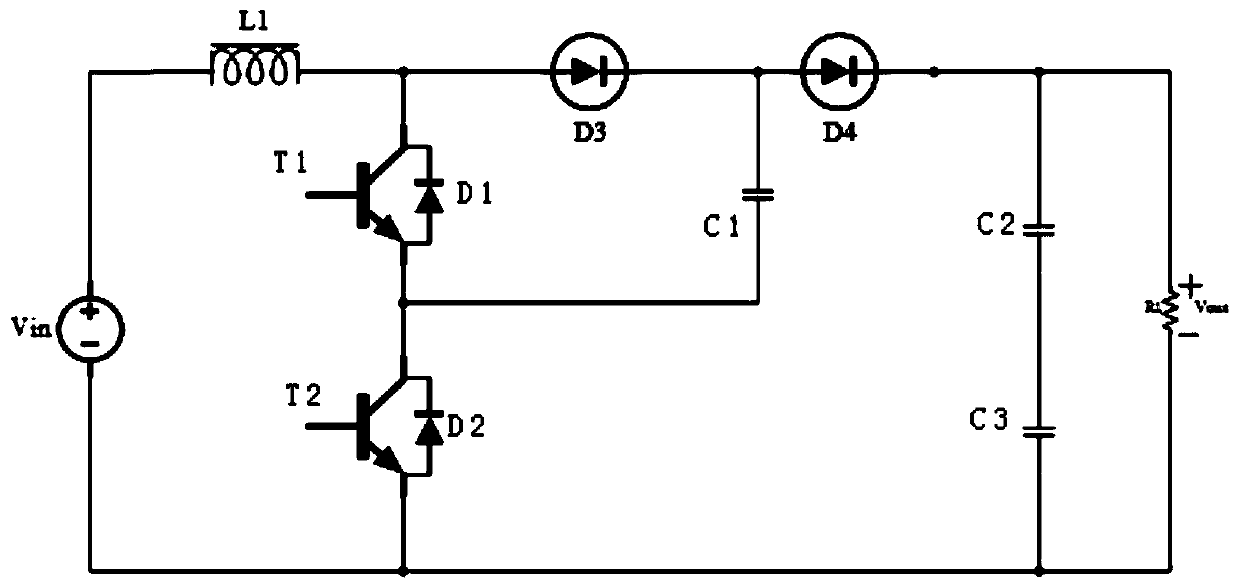

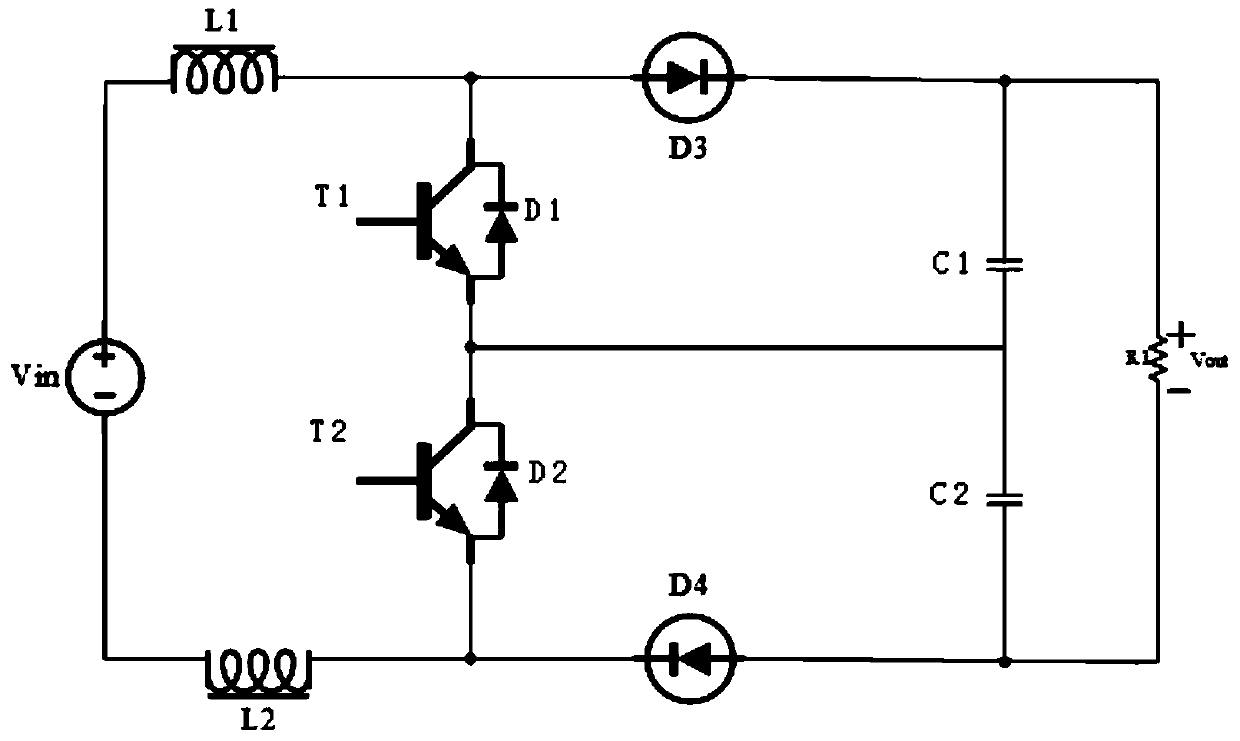

[0029] like Figure 1-a As shown, resistor R1 is the load unit, C3 and C4 are the bus capacitors on the output side of the Boost circuit, according to the input voltage V in and the output voltage V out The relationship between the Boost circuit and the duty cycle D 0.5 two operating modes respectively:

[0030] 1. When V in >0.5V out When the duty cycle D < 0.5;

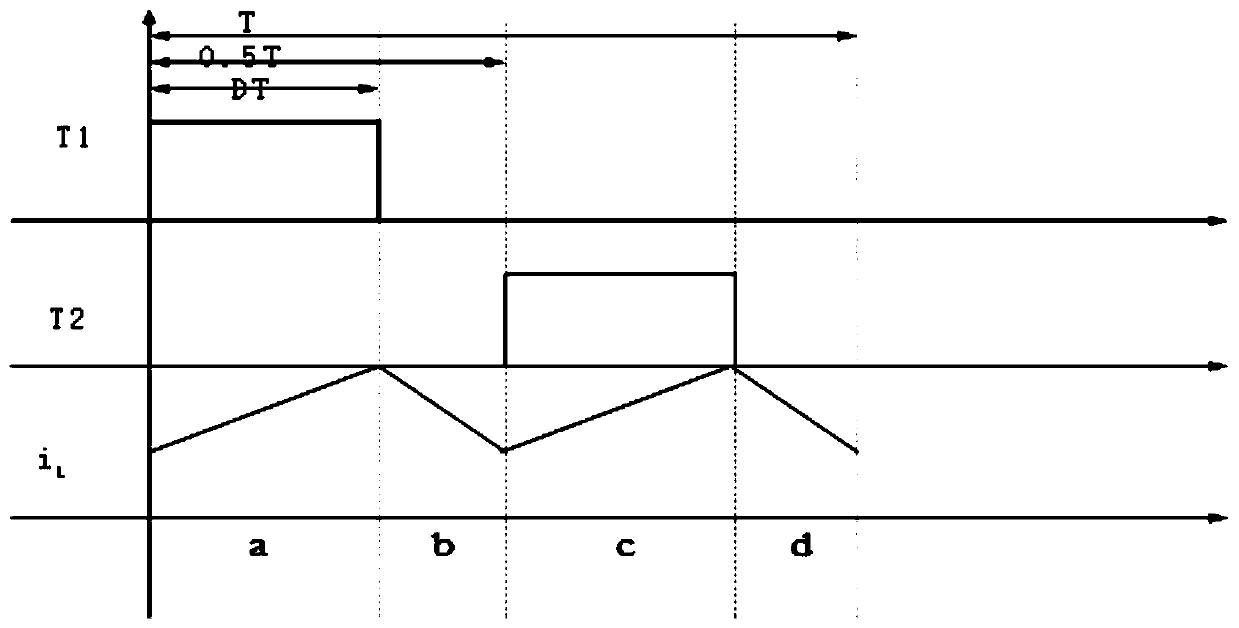

[0031] In this working mode, the waveform of the driving signal is as follows figure 2 As shown, the current flow paths in each switching mode are as follows Figure 3-6As shown, the realization represents the current flow path, and C2 and C3 are the bus capacitors. In the figure, T is the switching period, and the driving signals of T1 and T2 differ by a phase angl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com