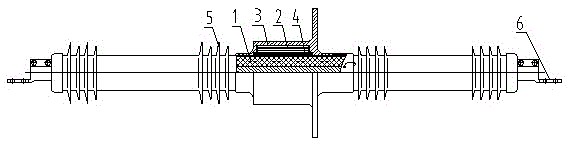

Dry capacitive-type through wall-penetrating bushing employing impregnated fiber

A wall bushing and capacitive type technology, applied in the direction of lead-in/through-type insulators, electrical components, etc., can solve problems such as partial discharge of bushings, corrosion of metal parts, and reduce the stability of bushing operations, so as to improve stability , Increase the effect of insulation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The manufacturing method of a glue-impregnated fiber dry capacitive through-wall bushing described in this embodiment includes the following steps:

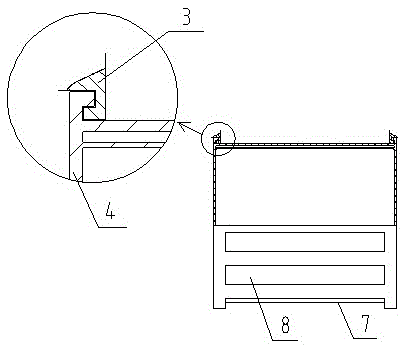

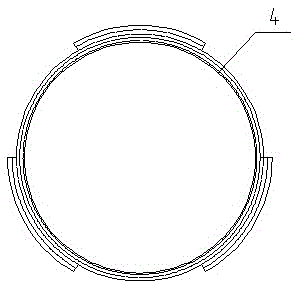

[0039] (1) Production of capacitor core: use winding equipment to wrap glass fiber on the central rod by directly impregnating resin. The winding adopts a two-way cross method. When winding two layers, apply a layer of semiconductor glue and repeat the operation until the winding reaches the specified During the winding process, keep the glass fiber crossing angle at 90°, put it into the oven for curing after completion, the curing temperature is controlled at 140°C, and the curing time: 3h, to ensure that the capacitor core is completely cured, and the capacitor core is according to the drawing The given dimensions are processed;

[0040] (2) Integrate the current transformer with the through-wall flange, and use epoxy resin to completely bond the inner wall of the casing to the surface of the capacitor core;

[0041] (3...

Embodiment 2

[0045] The manufacturing method of a glue-impregnated fiber dry capacitive through-wall bushing described in this embodiment includes the following steps:

[0046](1) Manufacture of capacitor core: use rolling equipment to roll the glass fiber to the specified thickness with a tension of 8kg according to the hoop splicing method, cover it with a layer of aluminum foil, and weld it with an 80W electric soldering iron At the lap joint of aluminum foil, repeat the operation until the specified layer thickness locks the end of the glass fiber to complete the rolling; put the rolled capacitor core into a vacuum tank, control the temperature at 145°C, and vacuum degree 50Pa for dehydration After 80 hours, cool down to 85°C, vacuum 3Pa, pour the prepared adhesive (mixed with bisphenol A epoxy resin and phenolsulfonic acid in a ratio of 2:1) onto the surface of the capacitor core, and the pouring time 26h, take it out after completion, and then heat up and solidify. The temperature co...

Embodiment 3

[0062] The manufacturing method of a glue-impregnated fiber dry capacitive through-wall bushing described in this embodiment includes the following steps:

[0063] (1) Capacitor core production: the steps (1) Capacitor core production method: use the rolling equipment to roll the glass fiber to the specified thickness with a tension of 10kg according to the hoop splicing method, and cover it with a layer of aluminum foil After the ring lap is joined, use an 80W electric soldering iron to weld the lap joint of the aluminum foil, and repeat the operation until the specified layer thickness locks the end of the glass fiber to complete the rolling; put the rolled capacitor core into a vacuum tank, and the temperature Control at 135°C, vacuum degree 60Pa, carry out dehydration treatment, after 70 hours, cool down to 95°C, vacuum degree 2Pa, mix the prepared adhesive (bisphenol A epoxy resin and phenolsulfonic acid in a ratio of 2:1 made) to the surface of the capacitor core, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com