Hydroxyapatite toothpaste and preparation method thereof

A technology of hydroxyapatite and nano-hydroxyapatite, which is applied in the field of daily chemical products, can solve the problems of easy failure of nano-hydroxyapatite and inability to repair dentin, etc., so as to promote the mineralization process, reduce the pore size, improve the The effect of the repair function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] This embodiment provides a hydroxyapatite toothpaste, which is calculated by mass percentage and consists of the following raw materials:

[0060] Calcium hydrogen phosphate dihydrate 12wt%, hydrated silica 10wt%, carrageenan 2wt%, glycerin 28wt%, sucralose 0.1wt%, zinc citrate 0.05wt%, sodium lauryl sulfate 2wt%, monofluorophosphoric acid Sodium 0.76wt%, peppermint flavor 1.25wt%, lemon yellow pigment 0.005wt%, micron hydroxyapatite 4wt%, nano hydroxyapatite 1wt%, and the balance is deionized water.

[0061] The method for preparing hydroxyapatite toothpaste includes the following steps:

[0062] S1. Put the above components in a mixer and stir for 40 minutes at 800 rpm;

[0063] S2, vacuum degass into a paste.

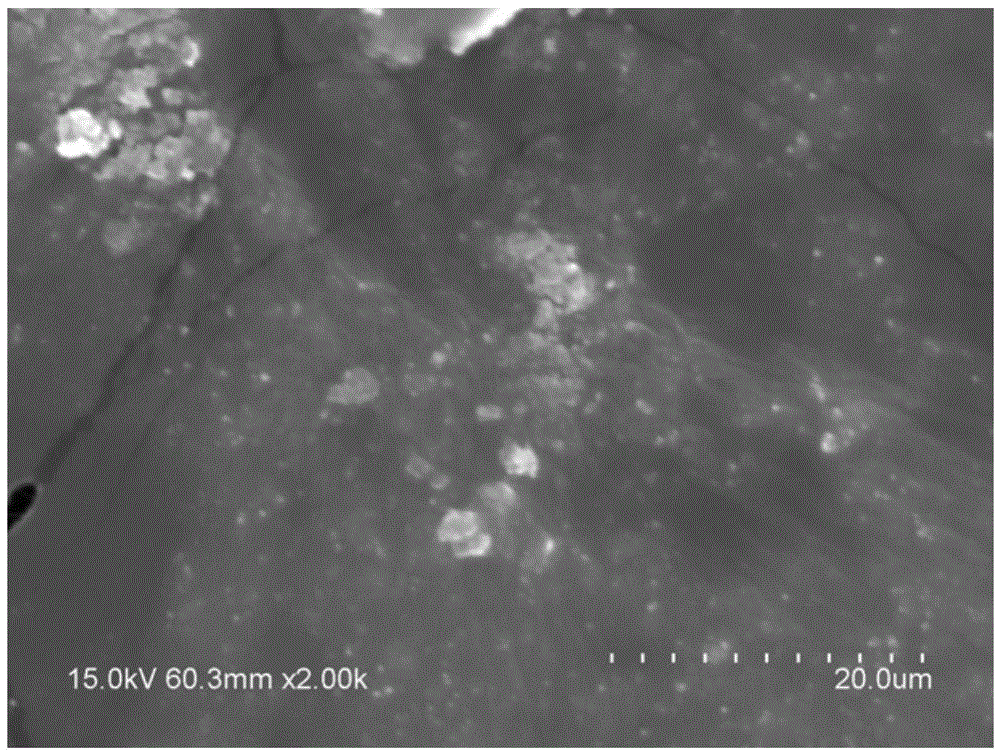

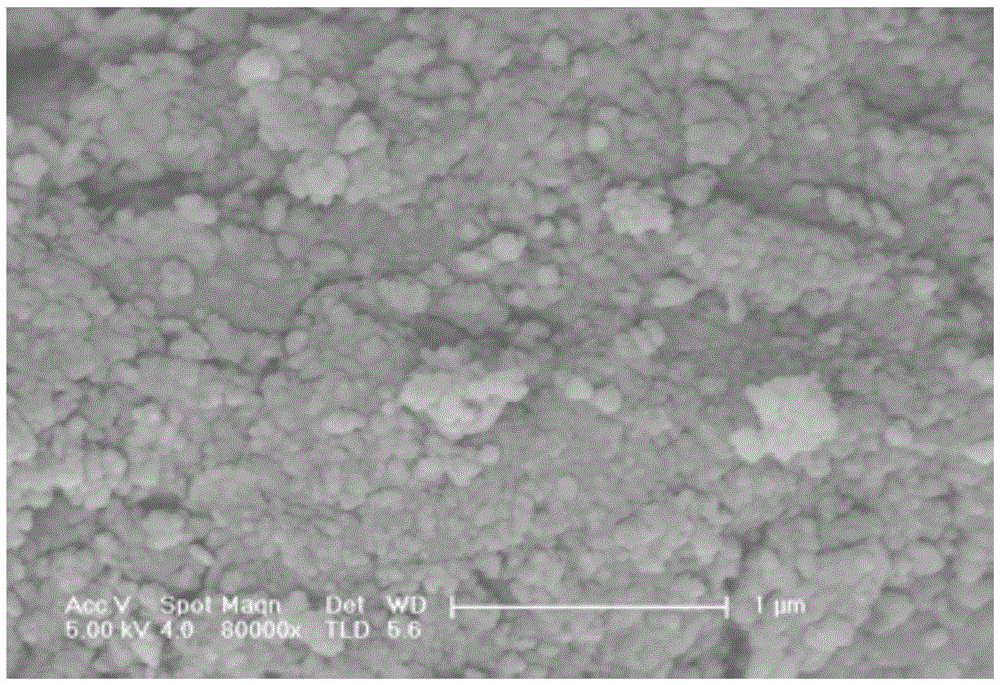

[0064] Such as figure 1 As shown, the average particle size of micron hydroxyapatite is 2μm; figure 2 As shown, the average particle size of nano-hydroxyapatite is 60 nm.

Embodiment 2

[0066] This embodiment provides a hydroxyapatite toothpaste, which is calculated by mass percentage and consists of the following raw materials:

[0067] Calcium hydrogen phosphate dihydrate 12wt%, carrageenan 2wt%, glycerin 28wt%, sucralose 0.1wt%, zinc citrate 0.05wt%, sodium lauryl sulfate 2wt%, sodium monofluorophosphate 0.76wt%, peppermint flavor 1.25wt%, lemon yellow pigment 0.005wt%, hydrated silica 10wt%, micron hydroxyapatite 3wt%, nano hydroxyapatite 2wt%, and the balance is deionized water.

[0068] The average particle size of micron hydroxyapatite is 2 μm, and the average particle size of nano-hydroxyapatite is 60 nm.

[0069] The method for preparing hydroxyapatite toothpaste includes the following steps:

[0070] S1. Put the above components in a mixer and stir for 40 minutes at 800 rpm;

[0071] S2, vacuum degass into a paste.

Embodiment 3

[0073] This embodiment provides a hydroxyapatite toothpaste, which is calculated by mass percentage and consists of the following raw materials:

[0074] Silica 40wt%, xanthan gum 0.02wt%, polyethylene glycol 40010wt%, methyl paraben 0.1wt%, sodium lauroyl sarcosinate 0.1wt%, sodium fluoride 8wt%, brilliant blue pigment 0.001wt %, micron hydroxyapatite 20wt%, nano hydroxyapatite 10wt%, and the balance is deionized water.

[0075] The average particle size of micron hydroxyapatite is 3 μm, and the average particle size of nano-hydroxyapatite is 80 nm.

[0076] The method for preparing hydroxyapatite toothpaste includes the following steps:

[0077] S1. Put the above components in a mixer and stir for 20 minutes at 100 rpm;

[0078] S2, vacuum degass into a paste.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com