Laser standard scribing method for low-speed diesel engine frame for ship

A laser datum, diesel engine technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems affecting operation safety, quality and efficiency, wind direction and environmental factors, and high labor intensity of workers, so as to improve measurement accuracy and efficiency. Operation efficiency, accurate measurement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

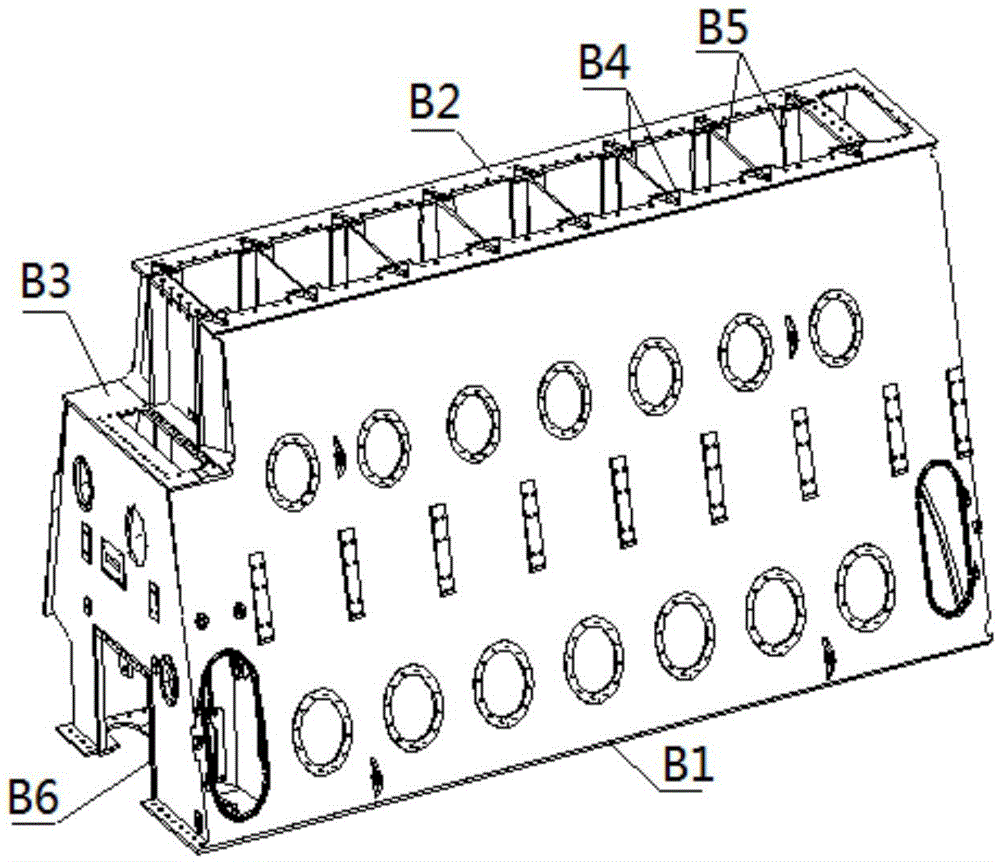

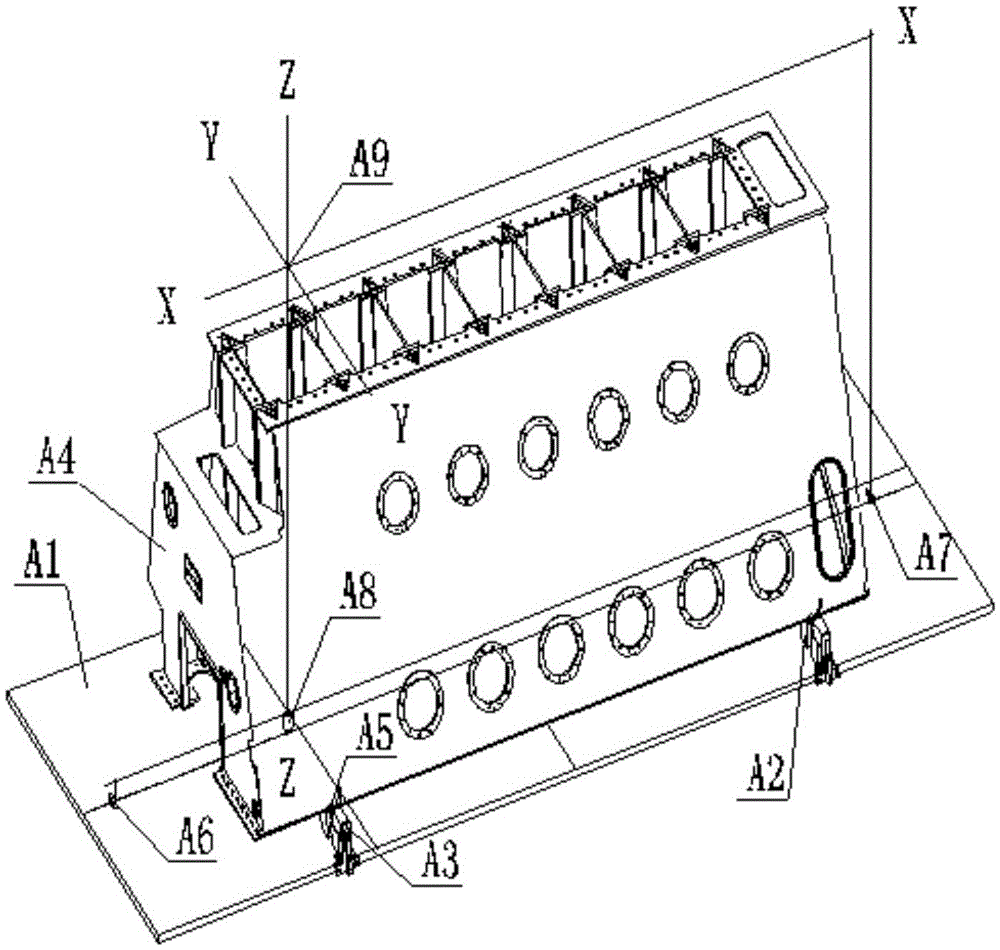

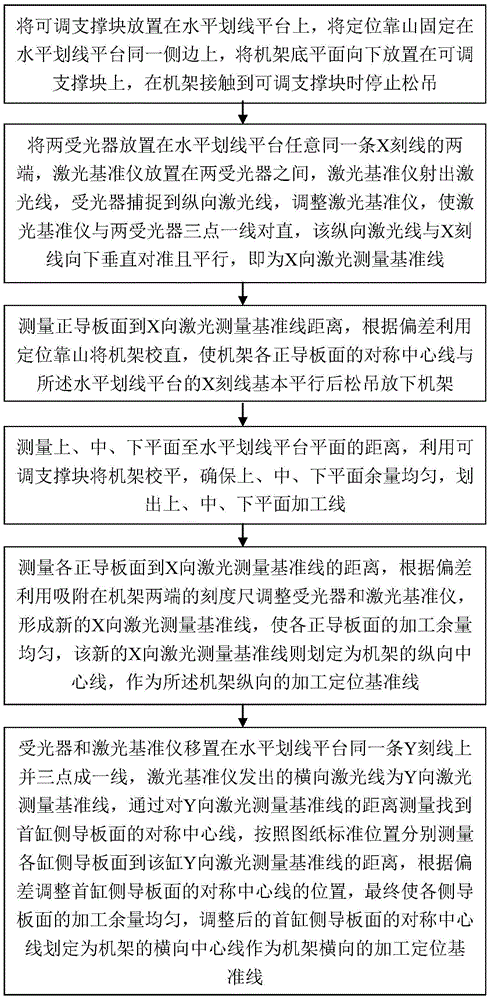

[0027] The laser reference marking method described in the present invention is used for marking the frame of a marine low-speed diesel engine, please refer to figure 1 The frame A4 is provided with an upper plane B2, a middle plane B3, and a lower plane B1 on the outside, and a number of symmetrical and evenly distributed positive guide plate surfaces B4 and side guide plate surfaces B5 perpendicular to the positive guide plate surface B4 are provided inside the frame A4. The front and rear sides of the frame A4 are provided with door frame holes B6. see figure 2 , the laser reference scribing method includes a horizontal scribing platform A1, a laser reference instrument A8, two light receivers A6 and A7, two positioning backers A3 and several adjustable support bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com