Anti-fogging packing material

A packaging material and anti-fogging technology, applied in the field of packaging materials, can solve the problems that cannot be removed directly, the effect is not very good, etc., and achieve the effects of increasing aesthetics, preventing condensation and adhesion, and being easy to process and roll.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

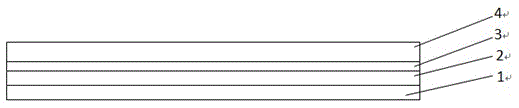

[0023] Such as figure 1 The anti-fog packaging material shown includes an adhesive base layer 1, an anti-fog layer 2, an adhesive layer 3, and a waterproof surface layer 4. The adhesive base layer is a polyethylene film, and the waterproof surface layer is a polytetrafluoroethylene film layer.

[0024] The polyethylene film thickness is 35 μm

[0025] The thickness of the zeolite anti-fogging layer is 40 μm

[0026] The thickness of the polytetrafluoroethylene film is 5 μm.

[0027] The anti-fogging layer 2 is composed of the following components: zeolite modifier: 3 parts, polypropylene: 91 parts, antioxidant 3 parts, calcium stearate 3 parts; the mass percentage of the zeolite modifier is: zeolite : 11 parts, EVA: 89 parts;

[0028] The preparation method of the anti-fogging packaging material is characterized in that it comprises the following steps:

[0029] 1) Preparation of zeolite modifier: mechanically blend zeolite and EVA according to the mass ratio of 11:89;

...

Embodiment 2

[0034] An anti-fog packaging material, comprising: an adhesive base layer, an anti-fog layer, an adhesive layer, a waterproof surface layer, the anti-fog layer, the adhesive base layer is polyethylene film, and the anti-fog layer is polypropylene , the zeolite is nano zeolite, the waterproof surface layer is a polytetrafluoroethylene film layer, and the thickness of the polyethylene film is 20 μm.

[0035] The thickness of the zeolite anti-fogging layer is 35 μm

[0036] The thickness of the polytetrafluoroethylene film coating is 20 μm.

[0037] The anti-fogging layer has the following components according to mass percentage: zeolite modifier: 1 part, polypropylene: 97 parts, antioxidant 1 part, calcium stearate 1 part; the mass percentage of the zeolite modifier is : Zeolite: 7 parts, EVA: 93 parts;

[0038] The preparation method of anti-fogging packaging material is characterized in that comprising the following steps:

[0039] 1) Preparation of zeolite modifier: mechan...

Embodiment 3

[0044] An anti-fog packaging material, comprising: an adhesive base layer 1, an anti-fog layer 2, an adhesive layer 3, and a waterproof surface layer 4, the adhesive base layer is polyethylene film, the anti-fog layer is polypropylene, and the The zeolite is nanometer zeolite, and the waterproof surface layer is a polytetrafluoroethylene film layer.

[0045] The anti-fog layer consists of the following mass percentages: zeolite modifier: 2 parts, polypropylene: 94 parts, antioxidant 2 parts, calcium stearate 2 parts;

[0046] The mass percentage of the zeolite modifier is: zeolite: 9 parts, EVA: 91 parts;

[0047] The anti-fogging packaging material according to claim 1, characterized in that the thickness of the polyethylene film is 28 μm.

[0048] The anti-fog packaging material according to claim 1, characterized in that the thickness of the zeolite anti-fog layer is 40 μm

[0049] The anti-fogging packaging material according to claim 1, characterized in that the thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com