Transfer printing equipment and coater

A technology of equipment and transfer plate, applied in rotary printing presses, printing presses, transfer printing and other directions, can solve the problems of printing deviation, product defects, etc., to improve contrast, avoid extension deformation and sliding, and ensure no deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

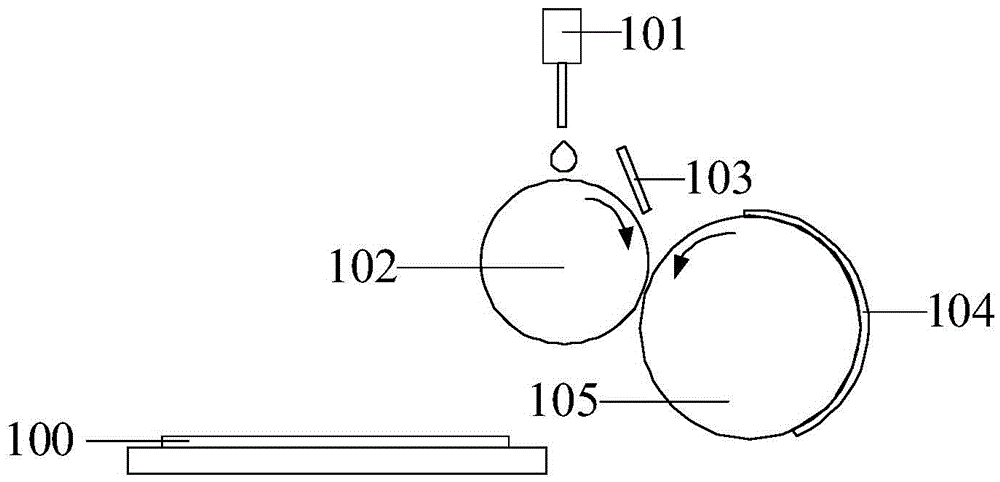

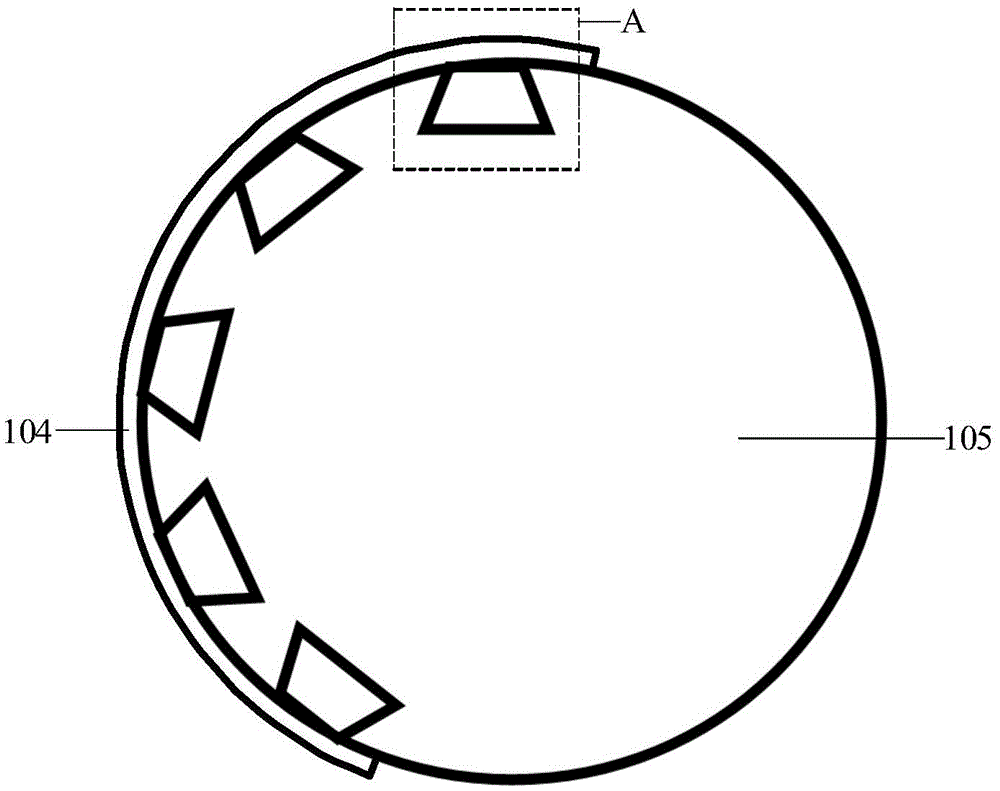

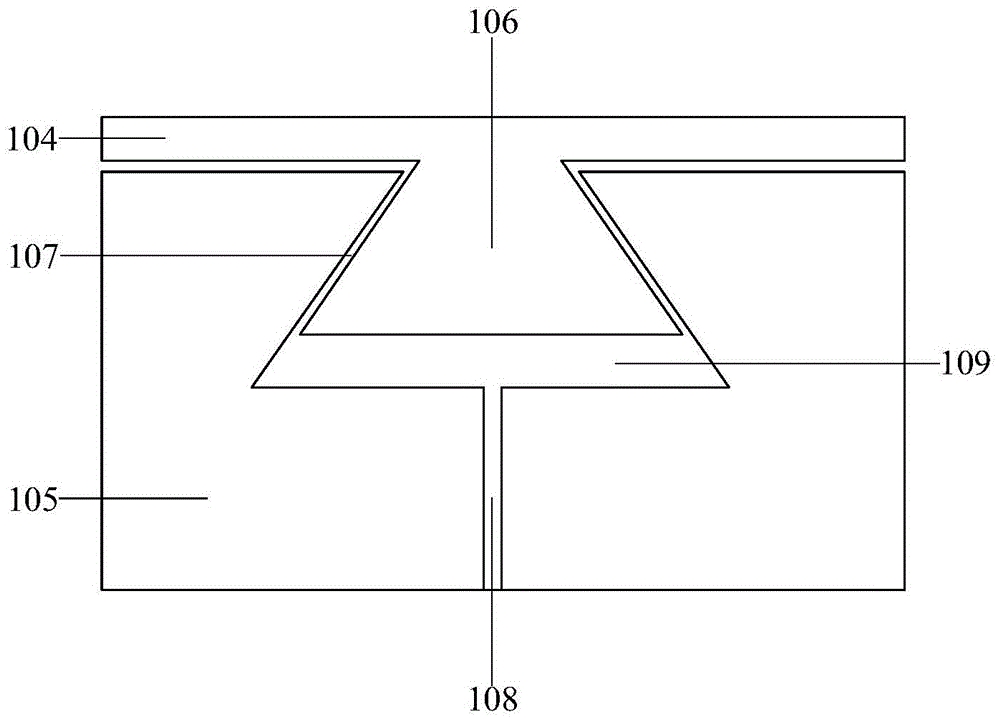

[0033] The alignment film in the display panel makes the liquid crystal molecules arrange in an orderly manner. Under the action of the electric field, the liquid crystal molecules rotate at a corresponding angle, so that the backlight can pass through the polarizer through the rotating liquid crystal to achieve the display effect. figure 1 Schematic diagram of the coating system. Such as figure 1 As shown, the specific implementation of the alignment film coating process is as follows: the dispenser 101 discharges polyimide (Polyimide, PI for short) onto the anilox roller 102, and the doctor blade 103 uniformly coats the discharged polyimide on the screen. Texture roller 102. The anilox roller 102 prints polyimide onto a pre-patterned transfer printing plate (Asai Kasai Photosenstive Resin Plate, APRPlate for short). The printing roller 105 transfers the polyimide onto the glass substrate 100 through the transfer plate 104 fixed thereon, and finally forms an alignment film....

Embodiment 2

[0043] The present invention provides a coating machine, including the transfer printing device provided in Embodiment 1. For details, please refer to the description of Embodiment 1, which will not be repeated here.

[0044] In the coating machine provided in this embodiment, the transfer device includes a transfer plate and a printing roller, and the protrusions of the transfer plate cooperate with the grooves of the printing roller to fix the transfer plate and the printing roller. The printing roller can not only solve the alignment problem between the transfer printing plate and the printing roller, but also optimize the orientation and uniformity of the alignment film by adjusting the ability of the transfer printing plate to accommodate polyimide, Thereby, the orderliness of the arrangement of the liquid crystal molecules is enhanced, and finally the contrast of the display panel is improved. In addition, the technical solution provided in this embodiment allows the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com