A printing steamer

A steaming and printing technology, used in printing, printing machines, general parts of printing machinery, etc., can solve the problem of large differences in the size of reactive and acid dyes, and achieve the effect of avoiding depth differences, rebound and impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

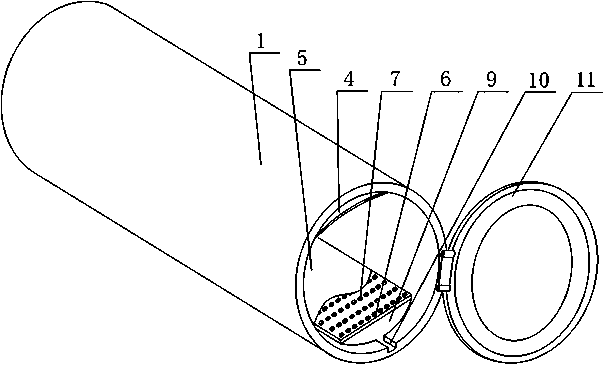

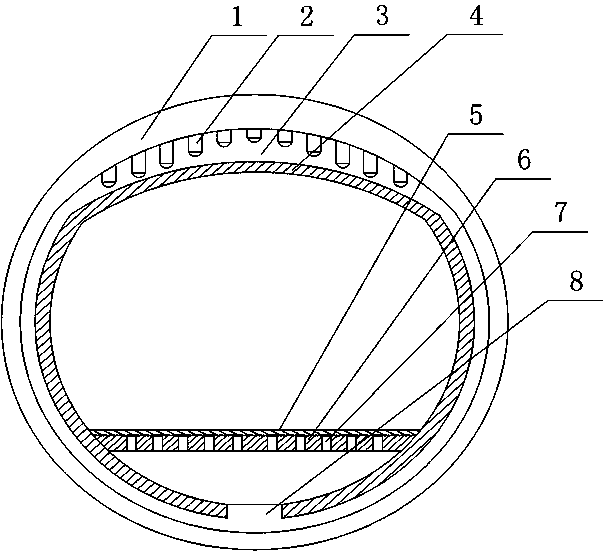

[0024] like figure 1 and figure 2 As shown, the present embodiment includes a tank body 1 and a cover body 11 hingedly fitted therewith, and also includes a partition 4, which is fixed on the inner wall of the tank body 1 and separates the inner peripheral wall of the tank body 1 into inferior parts located in the upper section. The arc wall and the superior arc wall located in the lower section, an interlayer is arranged on the inner wall of the tank body 1, a plurality of steam injection nozzles 2 are fixed on the inferior arc wall, and the partition plate 4 and the interlayer form a steam flow channel 3, A support plate 6 is installed on the superior arc wall, and a plurality of steam spray holes 7 are opened on the support plate 6 , and exit holes 8 corresponding to the steam spray holes 7 are opened on the steam channel 3 .

[0025] In the prior art, when the gray cloth is fixed, the steam is directly introduced from the side of the tank body 1, and the steam at the ste...

Embodiment 2

[0027] like figure 2 As shown, in this embodiment, the upper surface of the support plate 6 is covered with an insulating cloth 5, and a drainage channel 10 is opened at the lowest point of the arc wall. During the color fixing process, a large amount of steam directly interacts with the gray cloth through the steam injection holes 7 to ensure sufficient diffusion and penetration of the dye, so that the dye is fully combined with the fiber, but because the steam realizes point-to-point contact with the gray cloth through multiple steam injection holes 7 , the temperature at the contact point of the two is the highest, and it is easy to cause local overheating. In this embodiment, a layer of isolation cloth 5 is covered on the upper surface of the support plate 6, and the conductivity of the steam on the isolation cloth 5 is used to allow the steam to pass through. The insulating cloth 5 and the bottom of the gray cloth are fully and fully contacted, so as to prevent the gray ...

Embodiment 3

[0031] like figure 2 As shown, in this embodiment, the baffle 4 is arranged in a circular arc shape. Compared with the flat baffle 4, the smooth surface of the baffle 4 can be used to guide the steam ejected from the steam nozzle 2, avoiding The steam bounces and hits on the separator 4 to ensure the flow rate of the steam so as to improve the color fixing efficiency of the gray cloth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com