Sodium carboxymethylcellulose containing pentose structure unit

A technology of sodium carboxymethyl cellulose and carboxymethyl cellulose, which is applied in the field of active printing paste, can solve the problems of low utilization rate of etherifying agent chloroacetic acid, long production cycle, high production cost, etc., and achieve high cost performance and high production cost. The effect of short cycle time and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

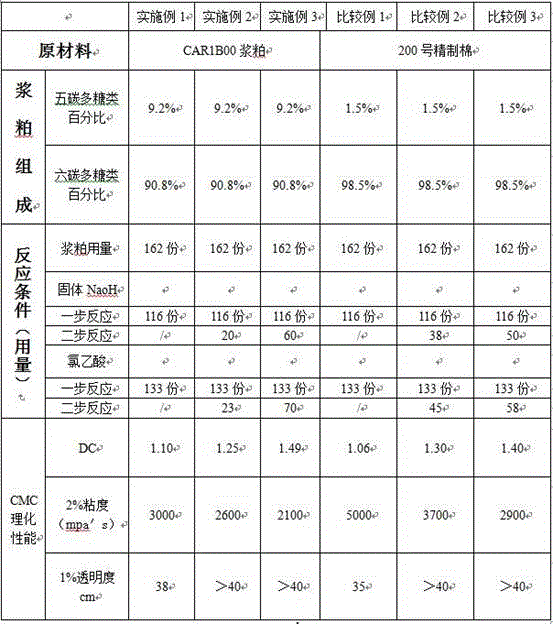

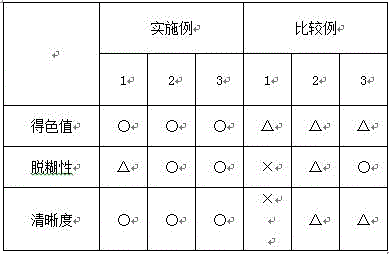

Embodiment 1-3

[0032] One-step reaction, the sodium hydroxide solution with a concentration of 48-49% is converted into 116 parts of solid caustic soda, and 300 parts of ethanol solution with a weight concentration of 91%, mixed and cooled below 20°C, and added to the kneader. Then put in 162 parts of a specific pulp cellulose, which contains 9.2% of five-carbon polysaccharides and 90.8% of six-carbon polysaccharides. After feeding, seal the feeding port of the kneader, fill it with nitrogen, and alkalize for 30-80 minutes , the alkalization is controlled at 15-25°C. After the alkalization is completed, add a 50-80% weight concentration of chloroacetic acid solution (equivalent to 133 parts of chloroacetic acid), etherify for 30-60 minutes, and control the etherification temperature at less than 50°C. After adding chloroacetic acid, raise the temperature to 75-80°C and continue etherification for 50-80 minutes. After the etherification is completed, discharge and neutralize to 7-8, then wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com