Combined engineering wood

A technology of engineered wood and wood strips, applied in the direction of joists, girders, trusses, etc., can solve the problems of difficult cutting, poor thermal insulation and sound insulation performance, and difficulty in nailing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

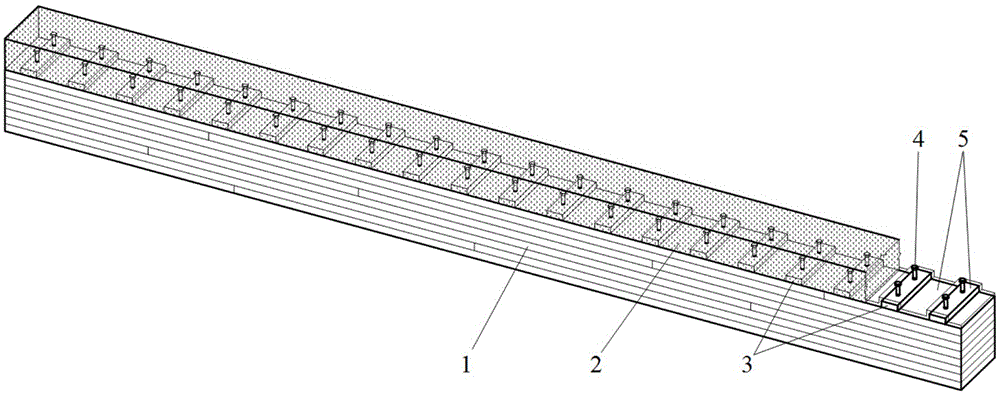

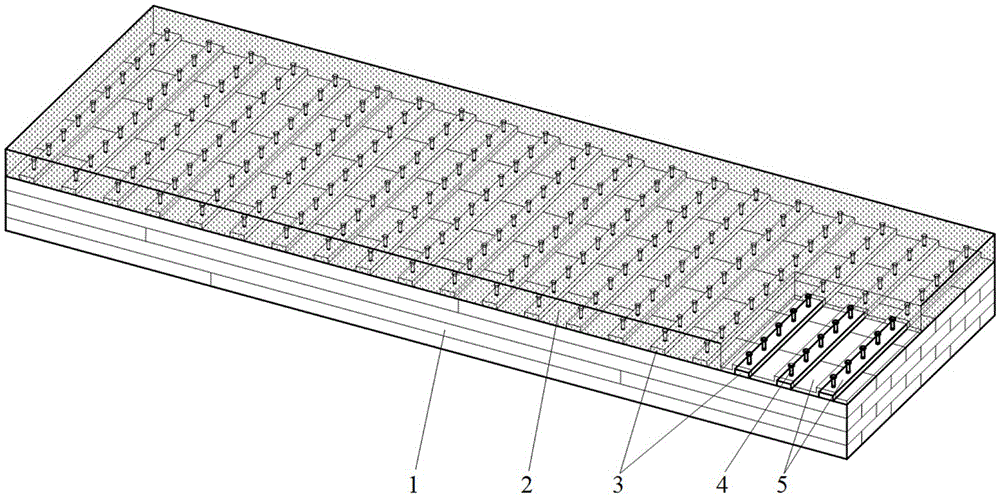

[0014] See figure 1 with figure 2 , The present invention is a composite engineering wood, which includes an engineering wood base plate 1 and a cement particle board 2, the cement particle board 2 is placed above the engineering wood base plate 1, the cement particle board 2 and the engineering wood base plate 1 through a shear connection and The glue layer 5 is connected, and the thickness of the cement particle board 2 is 1 / 2-1 / 4 of the thickness of the engineered wood floor 1. among them:

[0015] The engineered wood base plate 1 is composed of engineered glulam, or square wood or plank made of high-quality large-diameter logs, or laminated veneer lumber. For engineering glulam, it is produced in accordance with GB / T50708 "Technical Specifications for Glulam Structures", but the high-grade laminates should be placed underneath and the lower-grade laminates should be placed on top of the blank assembly.

[0016] The shear connector is composed of wood strips 3 and wood screws...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com