Particle shape analyzing device based on laser holography imaging method and working mechanism of particle shape analyzing device

A technology of particle shape and laser holography, which is applied in the field of particle analysis, can solve the problems of instrument calibration operation, large measurement error, and high cost of consumables, and achieve the effects of avoiding pollution, strong real-time performance, and wide detection objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

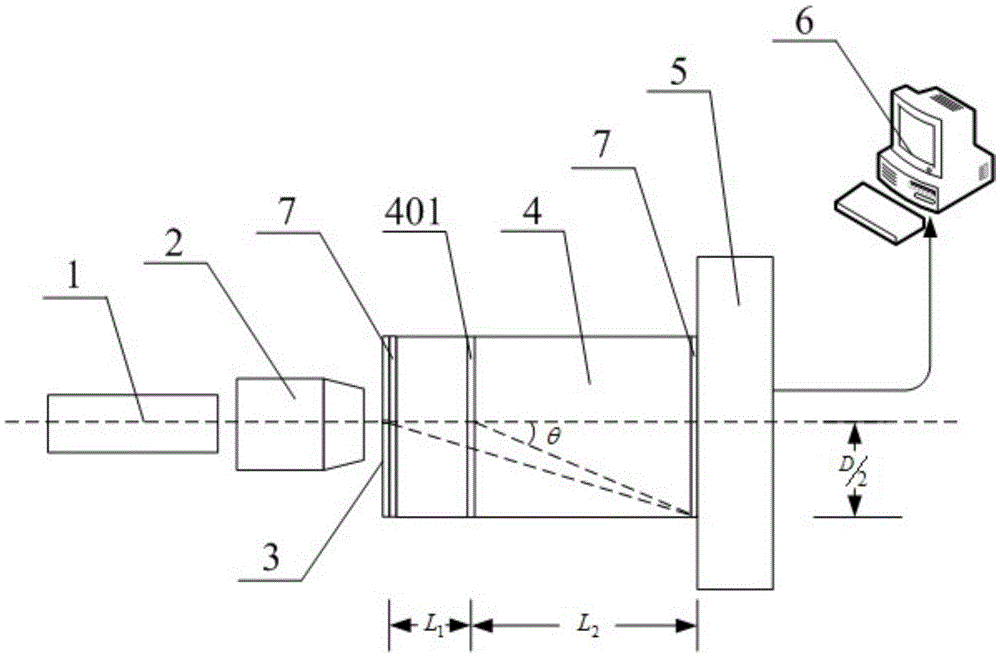

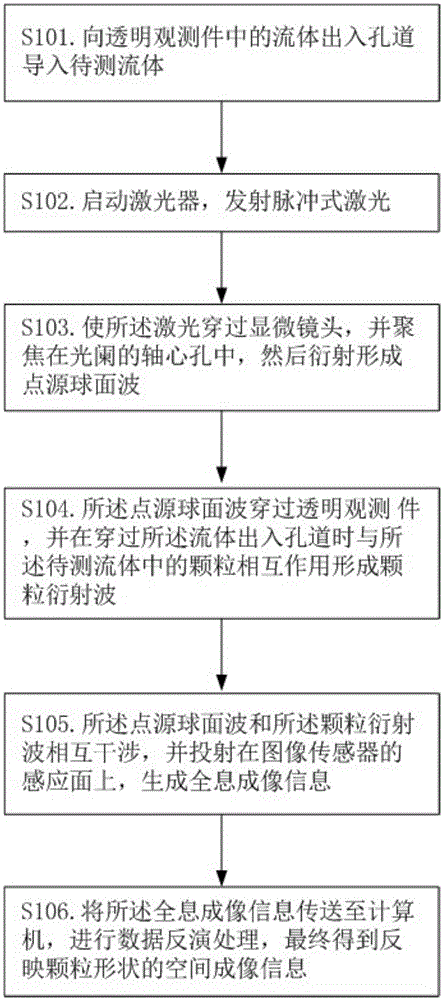

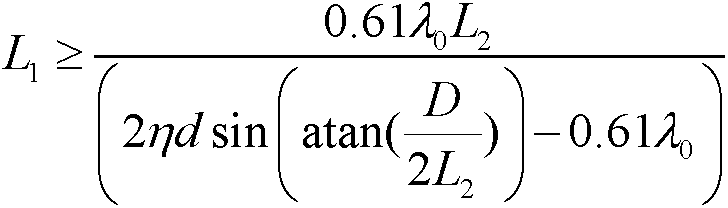

[0025] figure 1 A schematic structural view of a device for analyzing particle shape based on laser holographic imaging method provided by the present invention is shown, figure 2 A schematic diagram of the working process of the device provided by the present invention is shown. The device for analyzing the shape of particles based on the laser holographic imaging method provided in this embodiment includes a laser 1, a microscope lens 2, a diaphragm 3, a transparent observation piece 4 and an image sensor 5, wherein the transparent observation piece 4 is opened with The fluid access channel 401; the laser 1, the microlens 2, the aperture 3, the transparent observation member 4 and the image sensor 5 are arranged on the same axis in sequence, and the optical focus of the microlens 2 Located in the axial center hole of the diaphragm 3, the end face of the diaphragm 3 is against the first end face of the transparent observation member 4, and the second end face of the transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com