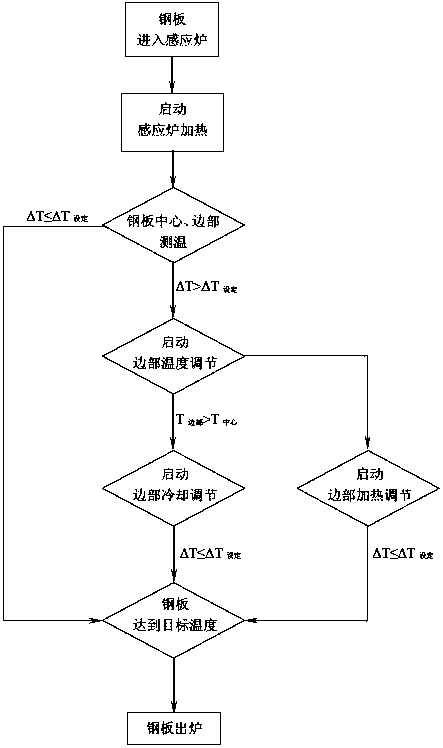

Edge temperature control method and control device in steel plate induction heating process

A temperature control method and a technology of a temperature control device, which are applied in the directions of temperature control, non-electric variable control, control/regulation system, etc., can solve the problem that there is no temperature adjustment function at the edge of the steel plate, the lack of a method for controlling the temperature at the edge, and the inability to realize temperature adjustment and other problems, to achieve the effect of fast and flexible switching of heating and cooling functions, real-time supplementary heating and cooling adjustment, and reduced edge trimming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

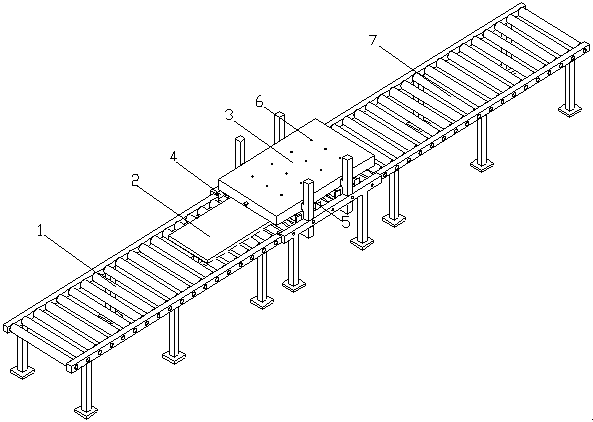

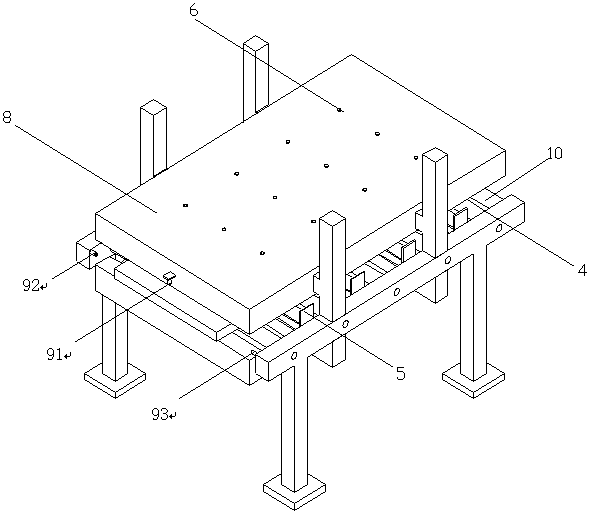

[0029] see Figure 2 to Figure 4 , a steel plate induction heating process edge temperature control device, including edge temperature adjustment system 5, displacement sensor 9, infrared temperature measuring device 6, intelligent processing unit, PLC control system, said infrared temperature measuring device 6 and displacement sensor 9 The output is connected to the intelligent processing unit, and the intelligent processing unit sends the calculation result to the PLC control system after calculation, and the output of the PLC control system controls the edge temperature adjustment system 5 .

[0030] The roller table system includes a roller table 1 in front of the furnace, a roller table 4 in the furnace and a roller table 7 behind the furnace. The induction heating furnace 3 includes an upper inductor 8 and a lower inductor 10, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com