Liquid milk product and preparation method thereof

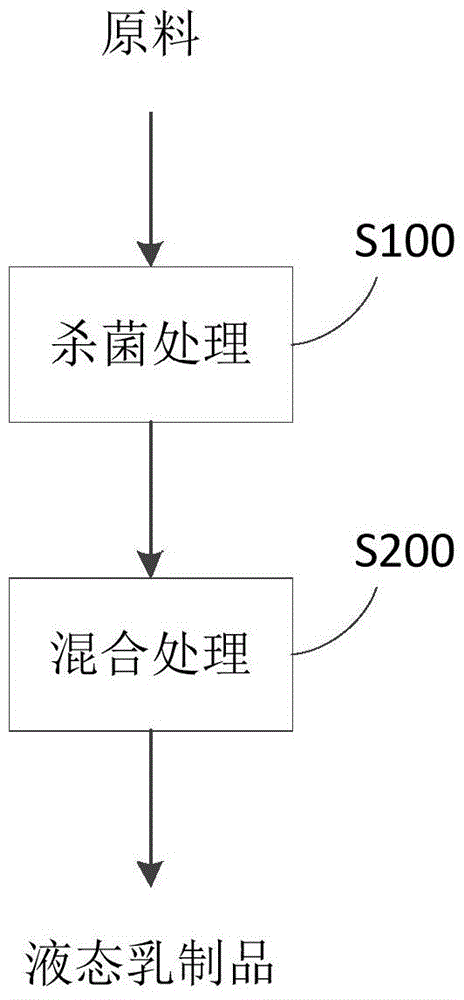

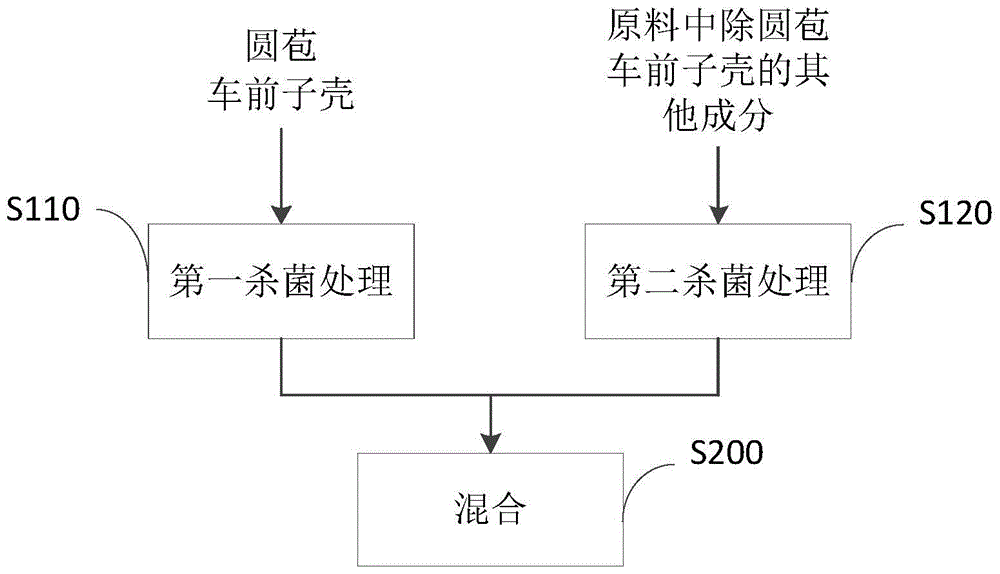

A dairy and liquid technology, applied in the field of liquid dairy products and their preparation, can solve problems such as the need for improvement of liquid dairy products, and achieve the effects of good flavor, strong suspension, and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

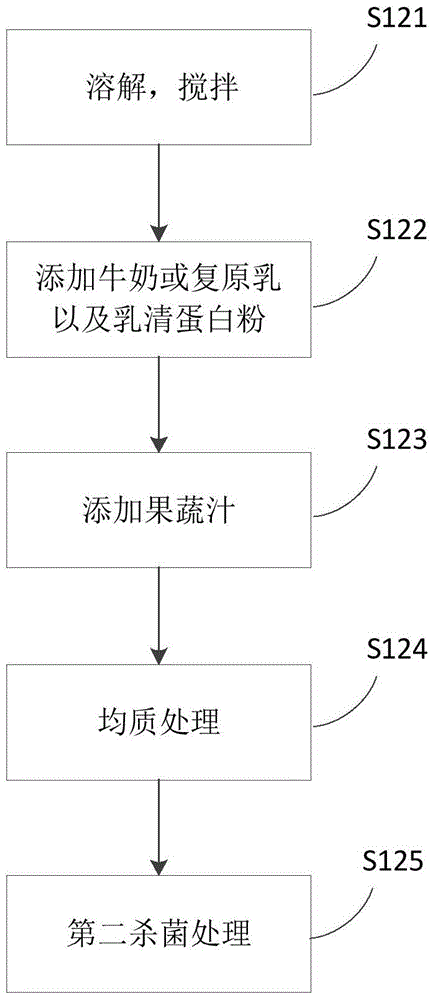

[0081] In this example, a liquid dairy product is prepared by the following steps:

[0082] (1) Mix and disperse 10 parts by weight of white granulated sugar, 15 parts by weight of soybean polysaccharide and 5 parts by weight of carrageenan in water at 70 degrees Celsius, stir at a speed of 400 rpm for 12 minutes, then add 0.1 parts by weight of steviol glycoside and 0.1 parts by weight of mogroside, stirred until completely dissolved, cooled to 30 degrees Celsius;

[0083] (2) Add 200 parts by weight of raw milk, 30 parts by weight of 80% whey protein powder and 50 parts by weight of 34% whey protein powder to the mixture obtained in step (1), and mix them;

[0084] (3) Slowly add 0.5 parts by weight of banana juice and 0.5 parts by weight of pineapple juice to the mixture obtained in step (2) at a rotating speed of 500rpm;

[0085] (4) Preheat the mixture obtained in step (3) to 860 parts by weight and preheat to 60 degrees Celsius, and carry out homogenization treatment un...

Embodiment 2

[0089] In this example, a liquid dairy product is prepared by the following steps:

[0090] (1) Mix and disperse 40 parts by weight of white granulated sugar, 0.3 parts by weight of microcrystalline cellulose, 2 parts by weight of soybean polysaccharide and 0.1 parts by weight of gellan gum in water at 72 degrees Celsius, and stir for 18 minutes at a speed of 500 rpm , then add 0.2 parts by weight of mogroside, stir until completely dissolved, and cool to 30 degrees Celsius;

[0091] (2) Add 300 parts by weight of raw milk, 10 parts by weight of 80% whey protein powder and 40 parts by weight of 34% whey protein powder to the mixture obtained in step (1), and mix them;

[0092] (3) Slowly add 5 parts by weight of hawthorn juice, 10 parts by weight of celery juice and 10 parts by weight of pineapple juice to the mixture obtained in step (2) at a rotating speed of 600rpm;

[0093] (4) Preheat the mixture obtained in step (3) to 881 parts by weight and preheat to 64 degrees Celsi...

Embodiment 3

[0097] In this example, a liquid dairy product is prepared by the following steps:

[0098] (1) Mix and disperse 50 parts by weight of white granulated sugar, 0.2 parts by weight of carrageenan and 0.8 parts by weight of gellan gum in water at 74 degrees Celsius, stir at a speed of 450 rpm for 20 minutes, then add 5 parts by weight of steviol glycoside and 5 parts by weight of mogroside, stirred until completely dissolved, cooled to 30 degrees Celsius;

[0099] (2) Add 400 parts by weight of raw milk, 20 parts by weight of 80% whey protein powder and 30 parts by weight of 34% whey protein powder to the mixture obtained in step (1), and mix them;

[0100] (3) Slowly add 5 parts by weight of banana juice, 10 parts by weight of carrot juice and 10 parts by weight of watermelon juice to the mixture obtained in step (2) at a rotating speed of 700rpm;

[0101] (4) Preheat the mixture obtained in step (3) to 909 parts by weight and preheat it to 71 degrees Celsius, and carry out hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com