Manufacturing method and device for wheel-mounted brake discs and wheel-mounted brake discs obtained through manufacturing method and device

A manufacturing method and technology of brake discs, applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of unfavorable paint operation, paint is not easy to dry, a large number of waste products and corrections, etc., to achieve small deformation and convenient operation , High effect of anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Taking the cast steel wheel-mounted brake disc (outer diameter of 1000mm) of a high-speed train with a speed of 350km / h as an example, an embodiment of the manufacturing method of the wheel-mounted brake disc according to the present invention includes the following steps:

[0044] A. Making a casting device;

[0045] B. Making cores;

[0046] C, close the box;

[0047] D. Smelting and pouring;

[0048] E. Unpack the sand and clean it up;

[0049] F. Rough machining, heat treatment and finishing of castings;

[0050] The two wheel-mounted brake discs are butted together for integrated manufacturing to form a combined casting, and then the combined casting is separated into two independent wheel-mounted brake discs.

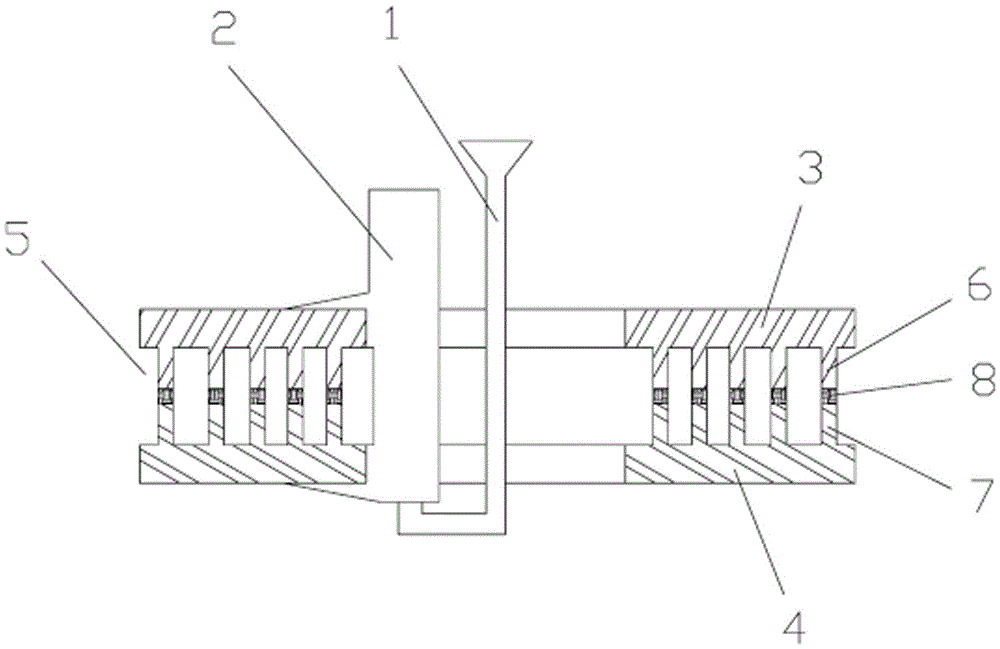

[0051] The manufacturing principle of the wheel-mounted brake disc of this embodiment is as follows: the wheel-mounted brake disc I and the wheel-mounted brake disc II have the same structure, both of which are disc-shaped structures with heat dissipati...

Embodiment 2

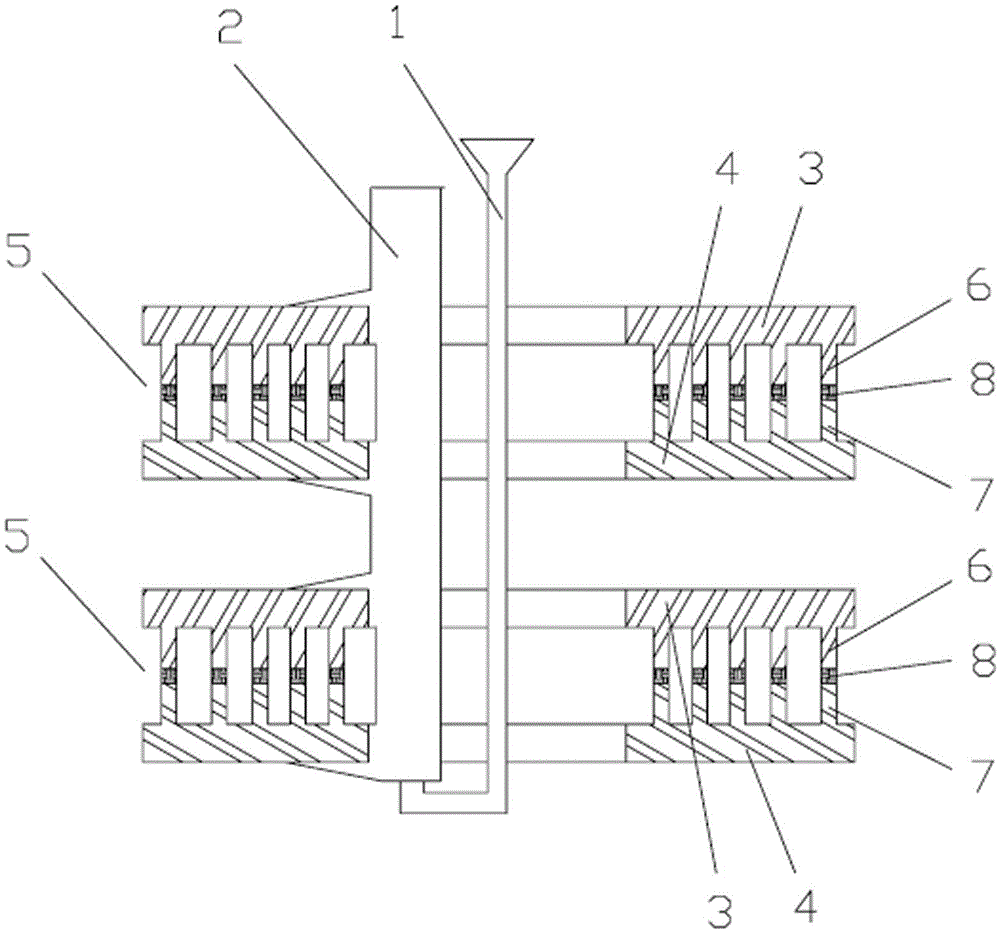

[0061] Taking the cast steel wheel-mounted brake disc (outer diameter of 1000mm) of a high-speed train with a speed of 350km / h as an example, another embodiment of the manufacturing method of the wheel-mounted brake disc according to the present invention, its process steps, principles and beneficial effects All are the same as the first embodiment, the difference is: this embodiment adopts the method of wire cutting to separate the combined casting before the casting is finished. In this embodiment, the method of introducing molten metal from the bottom is used for tandem casting, wherein the molten metal enters the cavity of this layer from the bottom of the next layer, and after the cavity of this layer is filled, the riser of the feeding system of this layer enters the upper layer. cavity.

[0062] like figure 2 As shown in the figure, the manufacturing device for the wheel-mounted brake disc of the present embodiment has the same structure, principle, connection relatio...

Embodiment 3

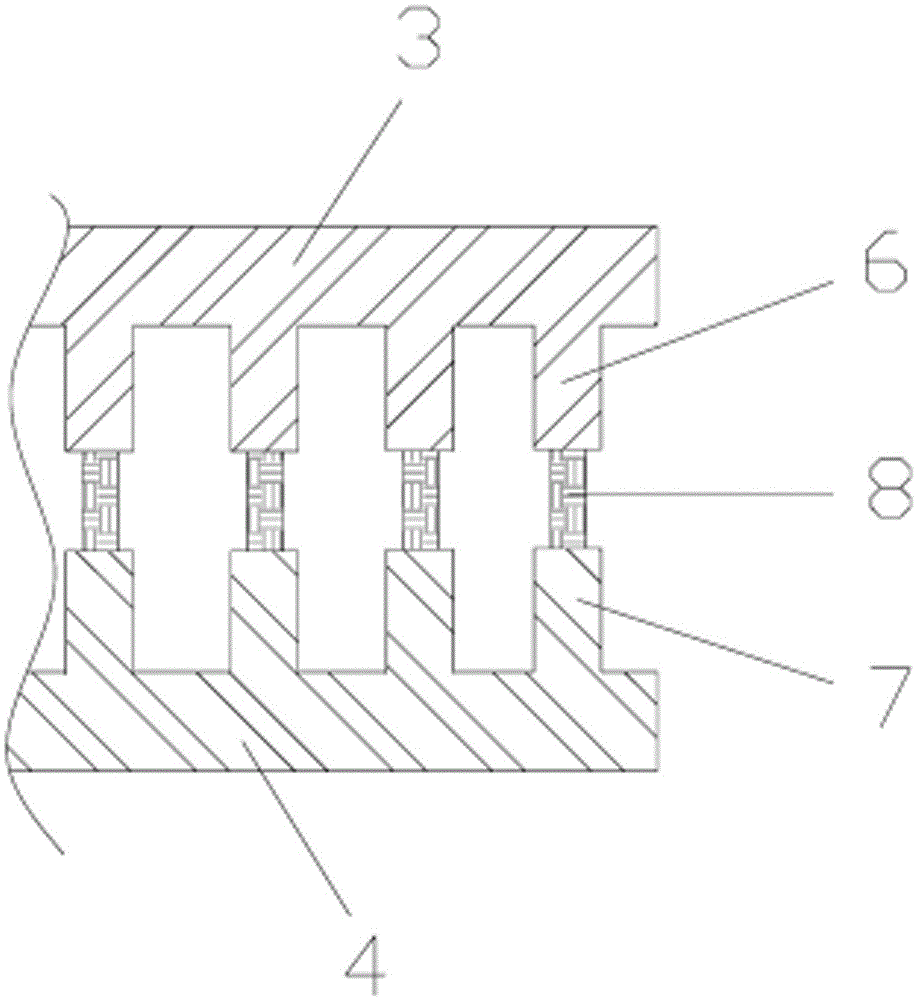

[0064] Taking the cast steel wheel-mounted brake disc (outer diameter of 1000mm) of a high-speed train with a speed of 350km / h as an example, its manufacturing method, manufacturing device, principle and beneficial effect are the same as those in the first embodiment, the difference is: this embodiment The combined casting is separated by flame cutting before rough machining of the casting. The length of the connecting rib is 100mm. The cross-sectional shape of the connecting rib is different from that of the heat-dissipating rib at the connecting part, and its cross-sectional area is smaller than the cross-sectional area of the heat-dissipating rib at the connecting part, such as image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com