Steel/aluminum dissimilar metal part laser deposition additive manufacturing method

A laser deposition, dissimilar metal technology, applied in the direction of additive processing, process efficiency improvement, energy efficiency improvement, etc., can solve the physical properties linear expansion coefficient brittle intermetallic compounds and mutual solubility, difficulty, constraints steel/aluminum dissimilar metals Parts application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

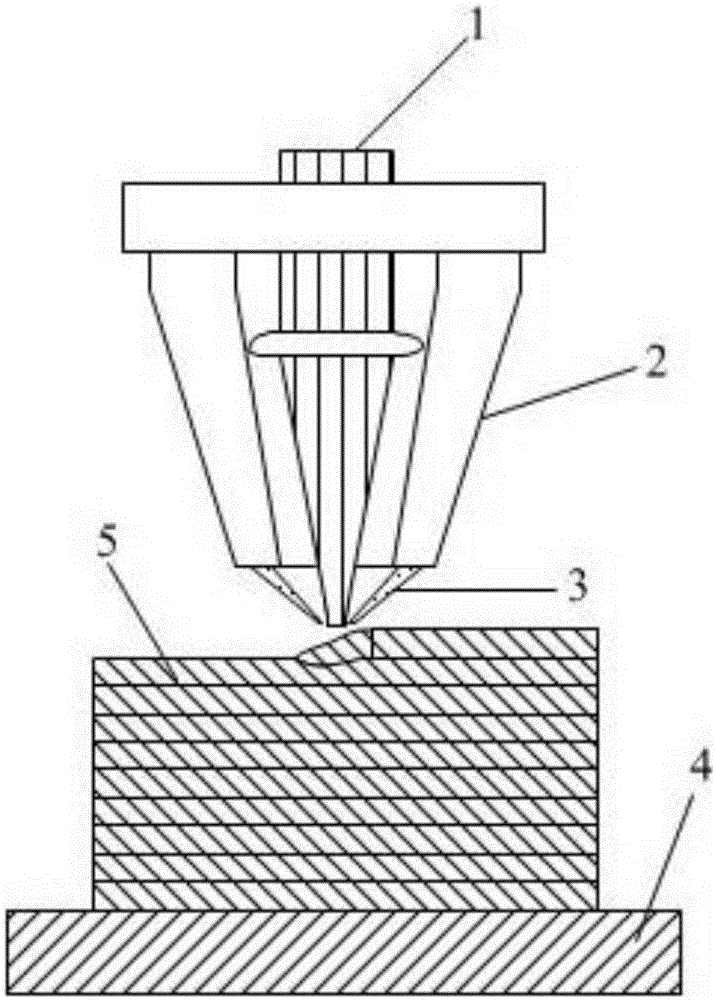

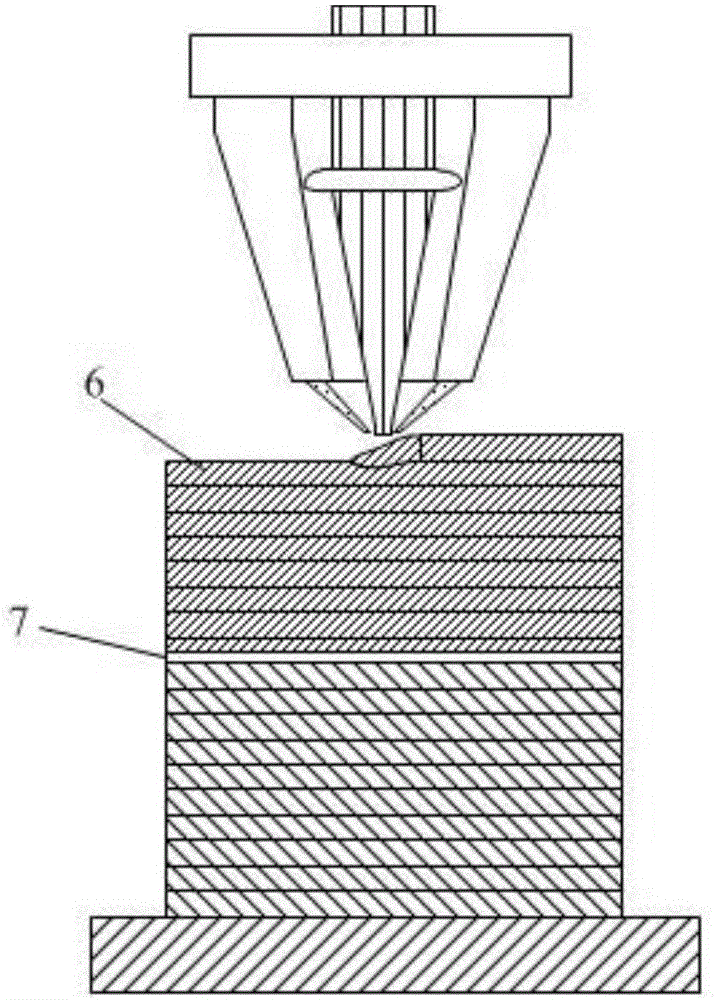

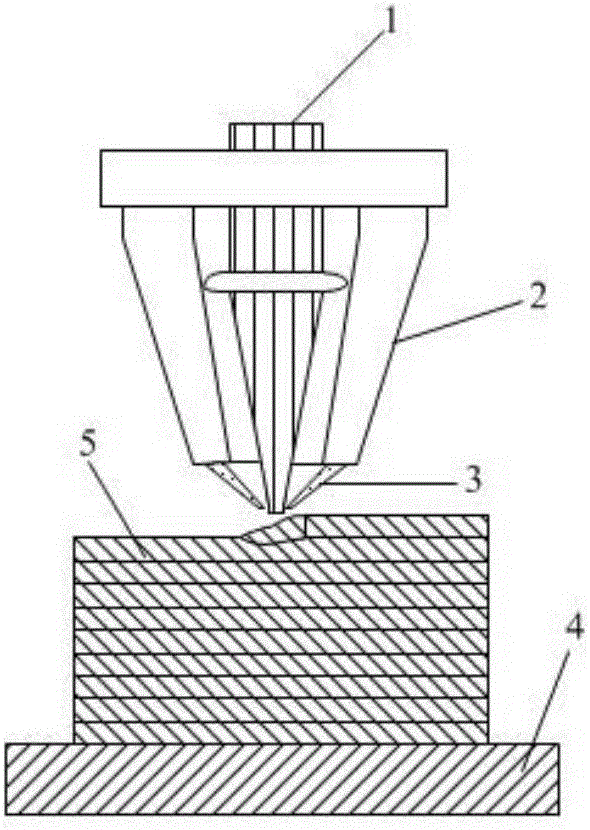

[0025] The specific content and implementation of the present invention will be further described below in conjunction with the accompanying drawings and specific examples.

[0026] The laser deposition additive manufacturing method for steel / aluminum dissimilar metal parts of the present invention includes the steps of progressively one-step continuous laser deposition additive manufacturing of steel / aluminum dissimilar metal parts or laser deposition aluminum alloy additive manufacturing on steel shaped parts. A progressive one-step continuous laser deposition additive manufacturing process for the steel / aluminum dissimilar metal parts,

[0027] 1. Laser deposit the steel part of dissimilar metal parts first;

[0028] 2. Then laser deposit the aluminum alloy part of the dissimilar metal part;

[0029] 3. When there is no transition layer between steel and aluminum alloy, when laser deposits aluminum alloy, the steel that has been formed by laser deposition does not melt, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com