An automatic bead discharge device suitable for narrow gap welding

An automatic row, narrow gap technology, applied in welding equipment, electrode support device, welding rod characteristics, etc., can solve the problems of large transmission gap of the welding torch rotating mechanism, large wear of the welding torch rotating transmission mechanism, and low control accuracy of the welding torch in place repeatedly. High repeatability in place, long service life, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

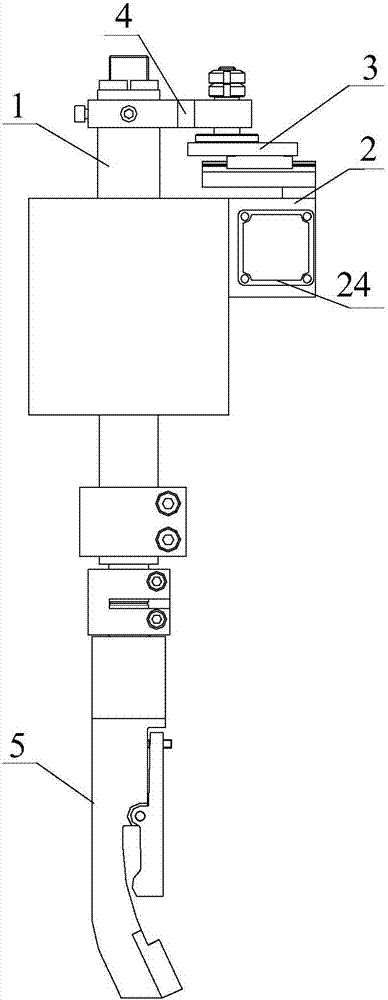

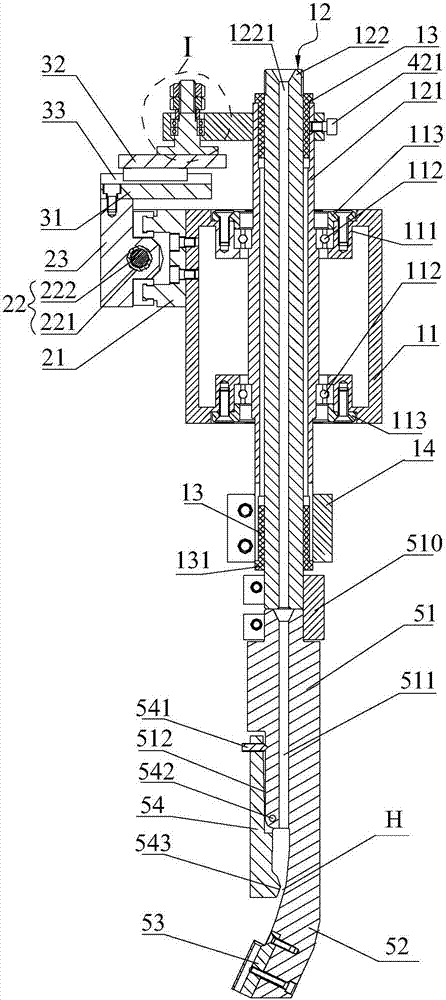

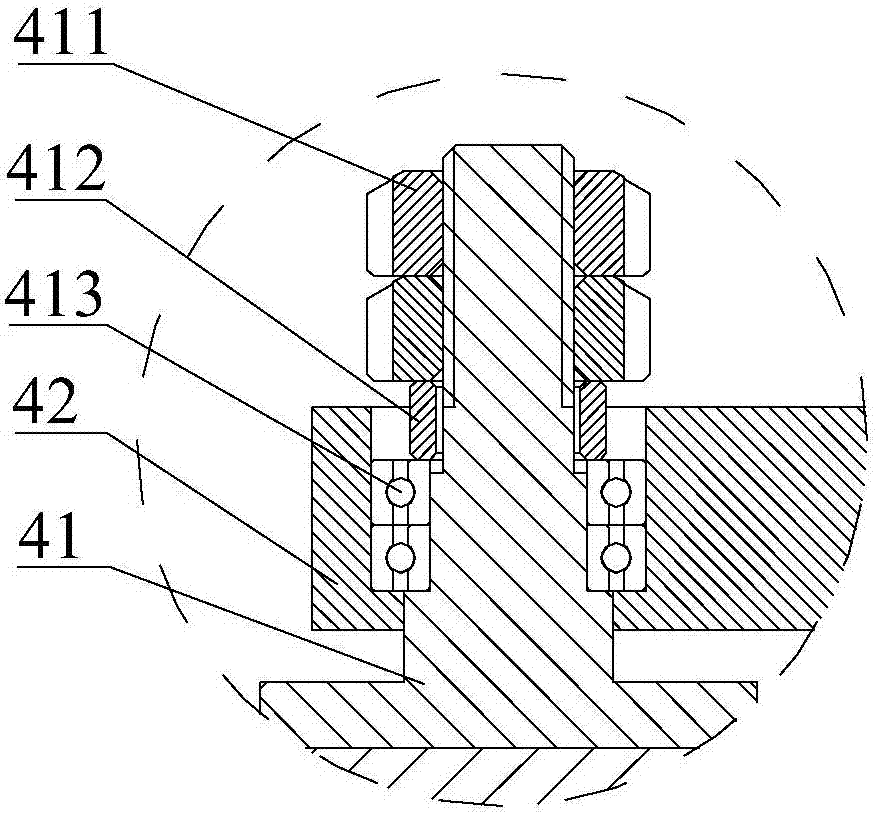

[0052]The invention proposes an automatic bead discharge device suitable for narrow gap welding, which includes: a gun angle rotating device, which is provided with a box body and a rotating rod for guiding welding wire, and the rotating rod can be rotated through The lower end of the box is connected with a welding torch; the transverse movement mechanism is fixed on the outside of the box through a transverse slide, and a horizontally placed horizontally placed between the two ends of the transverse slide Ball screw, the nut seat of the ball screw is equipped with a horizontal sliding table, one end of which is connected with the output shaft of a digital motor installed at one end of the horizontal sliding seat; the longitudinal follow-up mechanism includes a longitudinal sliding seat , a longitudinal slide and a longitudinal guide rail, the longitudinal slide is fixed on the upper end surface of the transverse slide, the longitudinal guide is mounted on the longitudinal sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com