Control device and method for wheel type mechanical hydraulic travelling system

A technology of mechanical hydraulics and control methods, which is applied in the direction of control devices, transportation and packaging, and driver input parameters. Operational fatigue and the effect of reducing throttling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

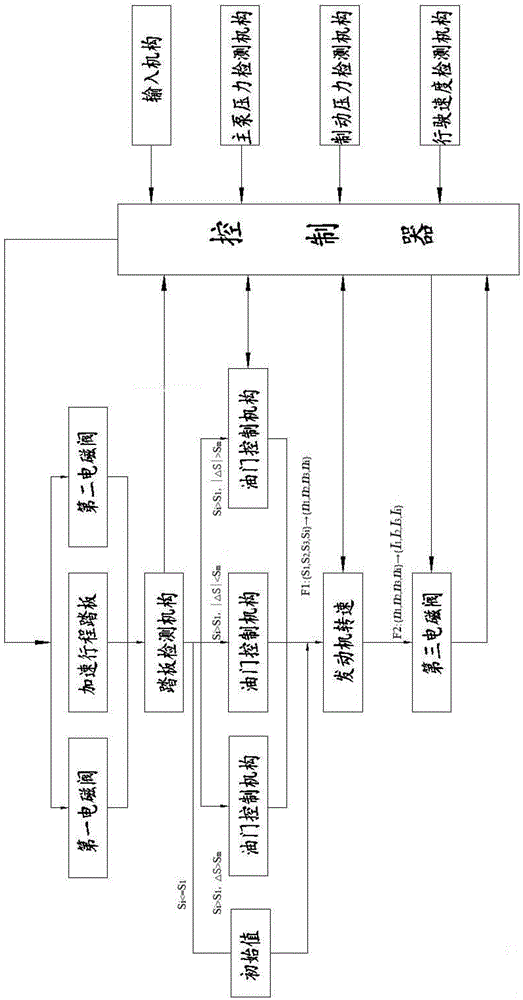

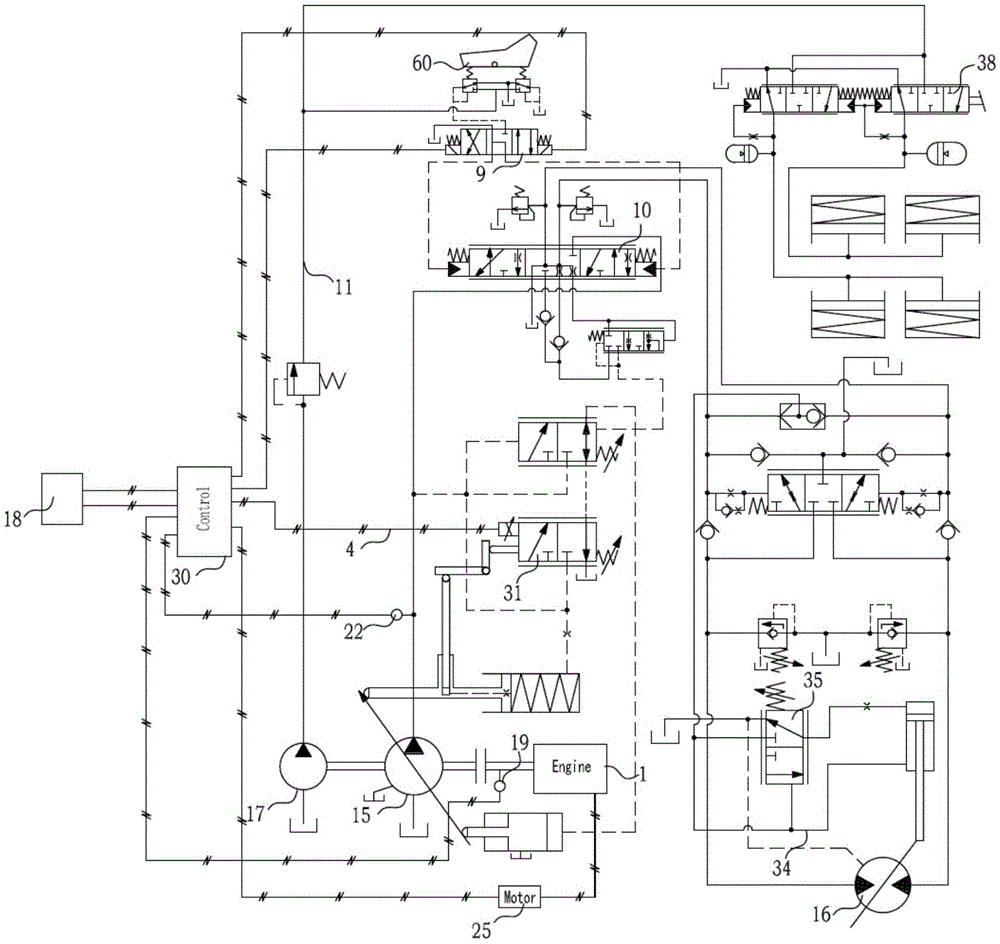

[0060] according to figure 1 As shown, the stroke of the accelerator pedal 7 is detected by the pedal detection mechanism 20, the pressure of the main hydraulic pump 15 is detected by the pressure detection mechanism 22, the pressure of the brake control valve 38 is detected by the brake pressure detection mechanism 39, and the rotational speed of the engine 1 is detected by the rotational speed Mechanism 19 detects, and travel speed detection mechanism 41 detects vehicle speed, and the detection signal of above-mentioned detection mechanism is jointly input into control unit 30, and display mechanism input mechanism 18 realizes data exchange and control with control unit 30, accelerator control unit 25, the first The solenoid valve 9, the second solenoid valve 12, the third solenoid valve 31 and the control unit 30 realize data exchange and control, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com