A method for constructing microbial co-culture system to produce bacterial cellulose

A technology of co-cultivation system and bacterial cellulose, which is applied in the field of microbial co-cultivation system construction, can solve problems such as high viscosity and consumption, and achieve the effects of optimizing growth conditions, strong operability, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

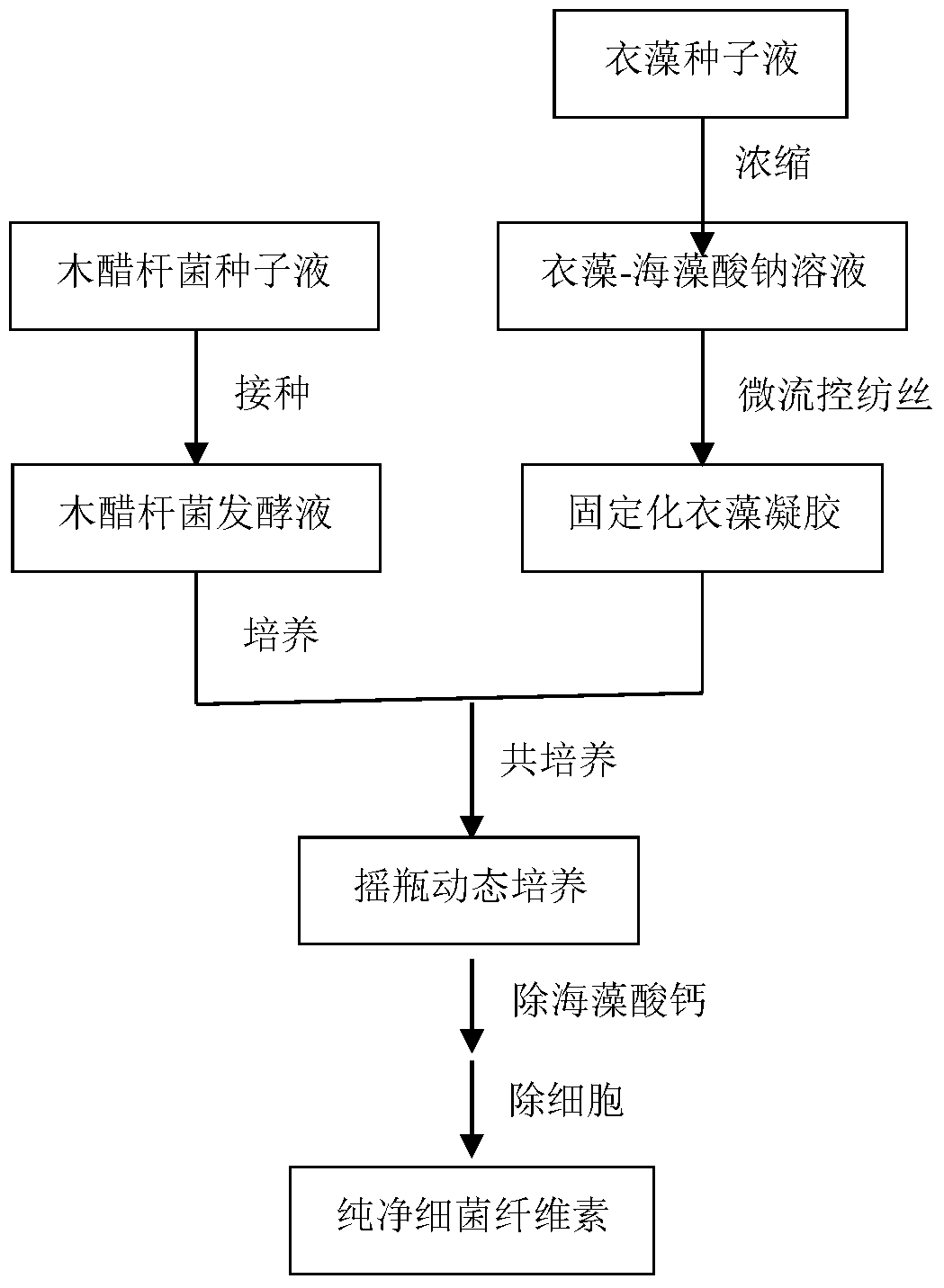

[0025] The present invention is a method for improving bacterial cellulose production by constructing a microbial co-cultivation system:

[0026] The first step: the two microorganisms are respectively expanded and cultivated in the seed solution. Acetobacter xylinum was cultured on a shaker at 30°C and 160 rpm for 36 hours, and Chlamydomonas was cultured in a light incubator at 22°C and 160 rpm for 36 hours to prepare various microbial seed solutions;

[0027] Step 2: After the Chlamydomonas seed liquid is concentrated by centrifugation, add 10mL of 0.8% (w / v) sodium alginate sol, mix evenly, and use a syringe pump to control the flow rate to 200mL / h and inject to a concentration of 1%. (w / v) immobilized in calcium chloride solution, the disposable syringe needle volume used for immobilizing Chlamydomonas is 10mL, and inner diameter is 0.4mm, and Chlamydomonas is fixed in the linear gel;

[0028] The third step: after Acetobacter xylinum is inoculated into the fermentation m...

Embodiment 2

[0031] The present invention is a method for improving bacterial cellulose production by constructing a microbial co-cultivation system:

[0032] The first step: the two microorganisms are respectively expanded and cultivated in the seed solution. Acetobacter xylinum was cultured on a shaker at 29°C and 150 rpm for 36 hours, and Chlamydomonas was cultured in a light incubator at 23°C and 160 rpm for 36 hours to prepare various microbial seed solutions;

[0033] Step 2: After the Chlamydomonas seed liquid is concentrated by centrifugation, add 10mL of 1.0% (w / v) sodium alginate sol, mix evenly, and use a syringe pump to control the flow rate to 200mL / h and inject to a concentration of 0.8% (w / v) immobilized in calcium chloride solution, the disposable syringe needle volume used for immobilizing Chlamydomonas is 10mL, and inner diameter is 0.4mm, and Chlamydomonas is fixed in the linear gel;

[0034] Step 3: After Acetobacter xylinum is inoculated into the fermentation medium w...

Embodiment 3

[0037] The present invention is a method for improving bacterial cellulose production by constructing a microbial co-cultivation system:

[0038] The first step: the two microorganisms are respectively expanded and cultivated in the seed liquid. Acetobacter xylinum was cultured on a 29°C 160rpm shaker for 36h, and Chlamydomonas was cultured in a 22°C 160rpm light incubator for 36h to prepare various microbial seed solutions;

[0039] Step 2: after the Chlamydomonas seed liquid is concentrated by centrifugation, add 10mL of 0.8% (w / v) sodium alginate sol, mix evenly, and use a syringe pump to control the flow rate to 200mL / h and inject to a concentration of 1.0% (w / v) immobilized in calcium chloride solution, the disposable syringe needle volume used for immobilizing Chlamydomonas is 10mL, and inner diameter is 0.4mm, and Chlamydomonas is fixed in the linear gel;

[0040] Step 3: After Acetobacter xylinum is inoculated into the fermentation medium with 10% inoculation amount, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com