Automatic clutch device with constant-power flow direction

An automatic clutch, constant power technology, applied in one-way clutches, clutches, mechanical equipment, etc., can solve the problem of idling in the direction of reverse power transmission, and achieve the effects of large economic application value, small size and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

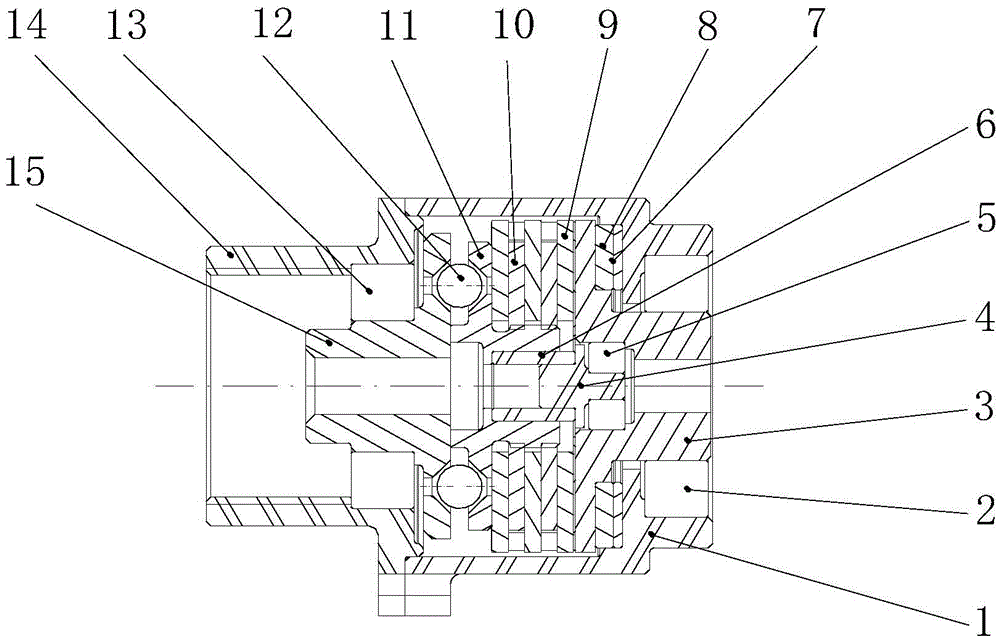

[0010] in figure 1 In the example shown, the entire structure is contained between the left housing 14 and the right housing 1, and power is only allowed to be transmitted from the input shaft 15 to the output shaft 3. When the torque and speed (whether clockwise or counterclockwise) act on the output shaft 3, the output shaft and the dynamic friction plate 10 are dragged to rotate, but due to the action on the top wave spring 6, there is no space between the dynamic friction plate 10 and the static friction plate 9 Positive pressure cannot transmit torque, that is, the static friction plate 9 and the input shaft 15 remain stationary, and the output shaft remains idling under drag; when the input shaft 15 is actively running (regardless of clockwise or counterclockwise), the ring on the input shaft 15 The inclined surface will push the steel ball 12 in the axial direction to move in a small range. After overcoming the resistance of the top wave spring 6 (only need 0.1~0.2mm str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com