Heat insulation and cold preservation method for liquefied gas cryogenic storage tank

A low-temperature storage tank and liquefied gas technology, which is applied in the field of thermal insulation materials, can solve the problems of loose installation structure of thermal insulation boards, failure of bonding, unstable connection between thermal insulation boards and storage tanks, etc. Easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

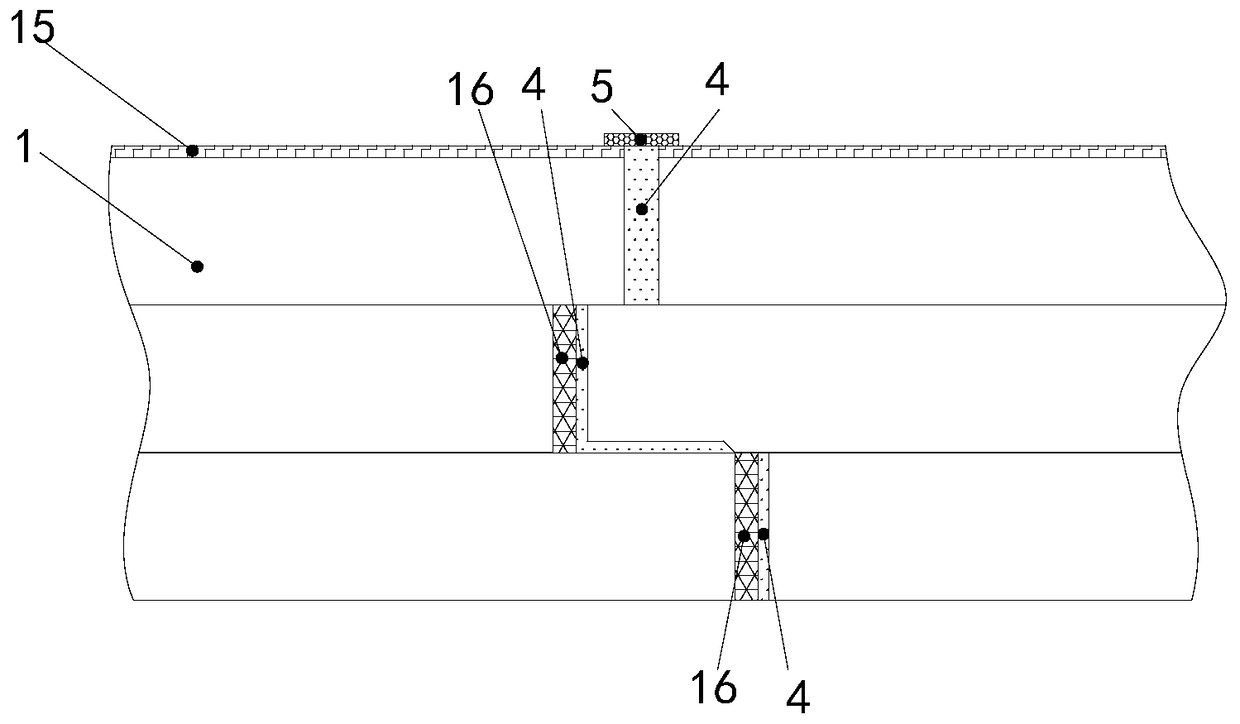

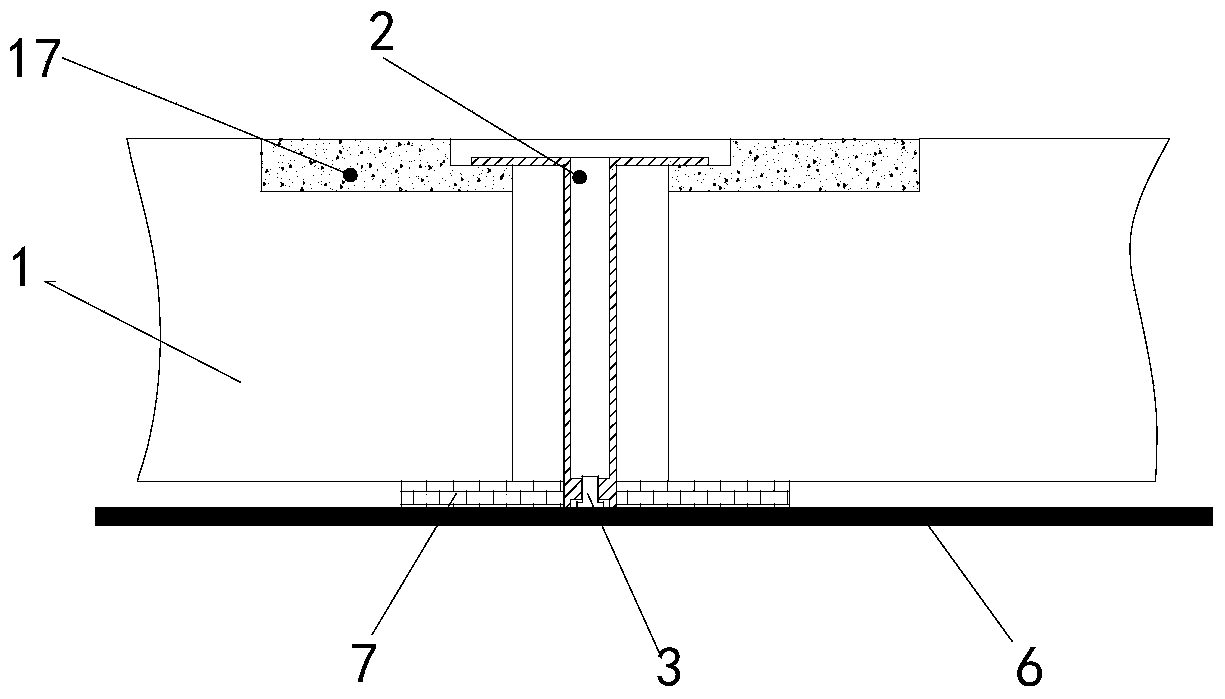

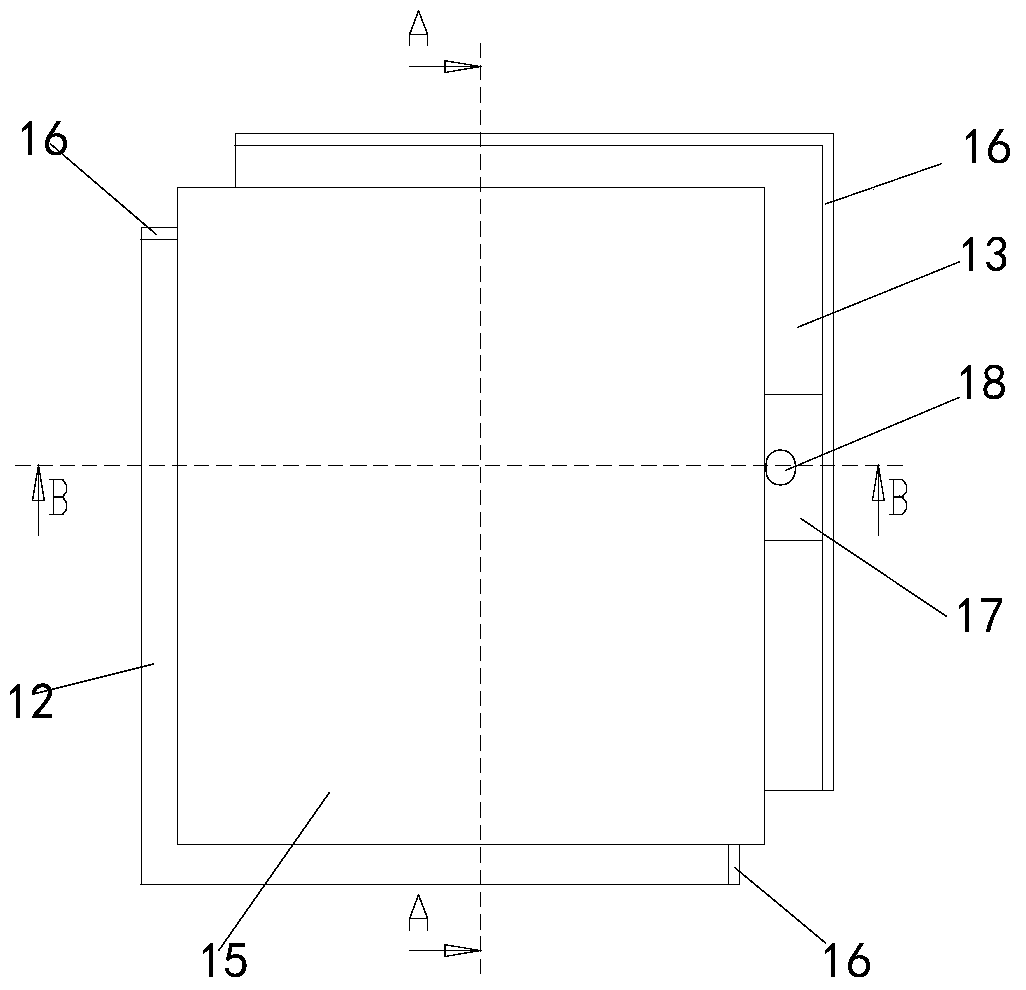

[0030] see figure 1 , figure 2 , with reference to image 3 , Figure 4 , Figure 5 , Figure 6 , the heat insulation and cold preservation method of the liquefied gas low-temperature storage tank of the present invention is to use the insulation boards 1 with a tenon joint structure to connect with each other, and form an integral insulation structure on the surface of the storage tank 6, and each insulation board passes through the fixed support 2 respectively. It is fixedly connected with the storage tank, and the storage tank is correspondingly provided with bolts 3 for threaded connection with the fixed support. The mortise and tenon joint surfaces between the insulation boards 1 are sealed with rigid polyurethane foam 4 by injection foaming, and the outer surfaces of the joints are sealed with silica gel 5 . figure 2 As shown in , 7 is a gasket.

[0031] The thermal insulation board 1 in the present invention includes the first thermal insulation layer 11, the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com