Method for vibration reduction and ground-collision splashing prevention of building blasting demolition

A building and anti-contact technology, applied in building construction, blasting, construction, etc., can solve the problems of notch blasting vibration, secondary splash hazards, etc., to improve safety, eliminate secondary splash hazards, reduce quantity and hazards Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with example, illustrate the embodiment of the present invention.

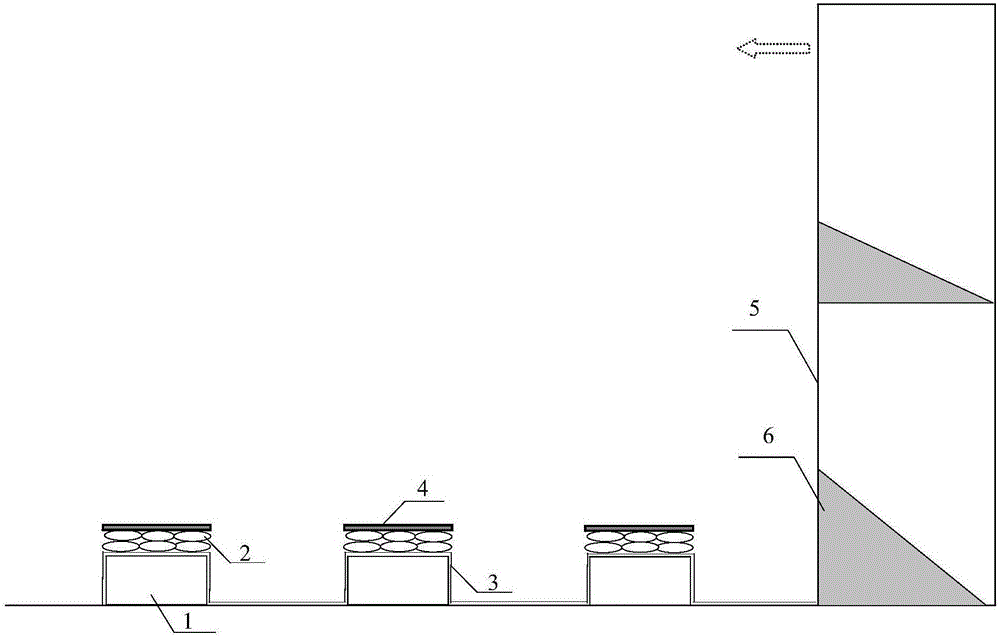

[0033] An 18-storey building is 63m in height, 21m in length, and 43m in width. There are residential buildings at 6m to the south, gas station facilities at 11m to the north, underground natural gas pipelines at 10m to the west, and factories and schools to the east at 40m. Double-fold in the same direction, and the collapse direction is due east.

[0034] During the blasting design process, after the safety check, the calculated value of the vibration generated by the collapse of the building is about 10 times higher than the allowable value of the vibration safety of the surrounding environmental facilities. Secondary splashing, adopted the present invention "a kind of method for building blasting demolition vibration reduction and anti-ground splash" to carry out vibration reduction and anti-ground splash, the steps are as follows:

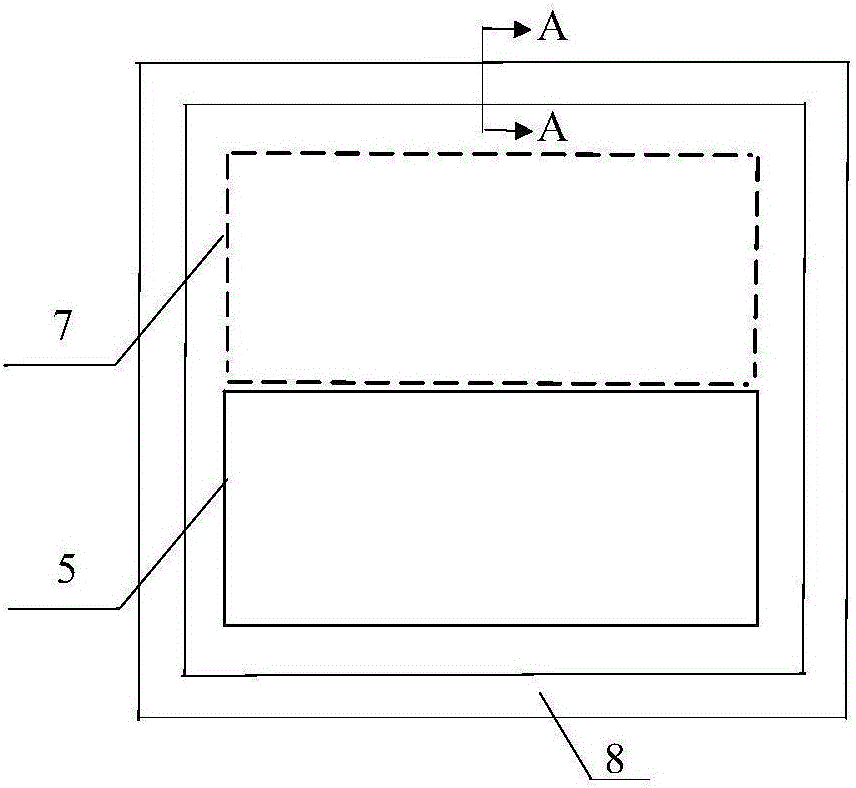

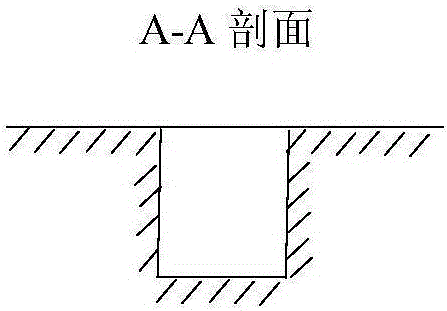

[0035] (1) Refer to figure 1 As shown, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com