Experimental device and experimental method for heat and mass transfer process of floating roof crude oil storage tank

A heat and mass transfer, crude oil storage tank technology, applied in the field of experimental research on heat and mass transfer laws, can solve problems such as lack of authenticity of experimental devices, and achieve the effects of rich test data, ingenious design, and enhanced flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Below in conjunction with accompanying drawing, the present invention will be further described:

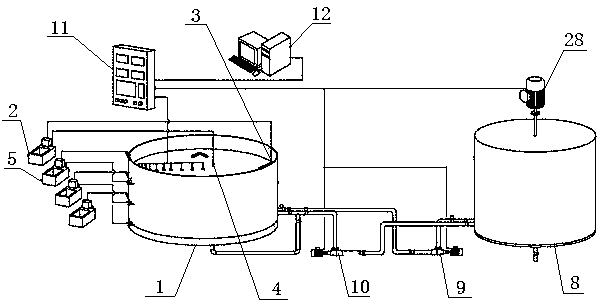

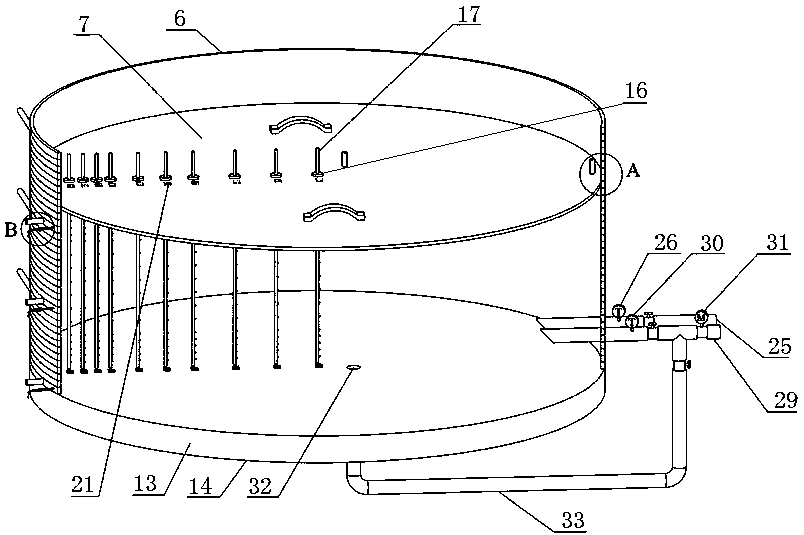

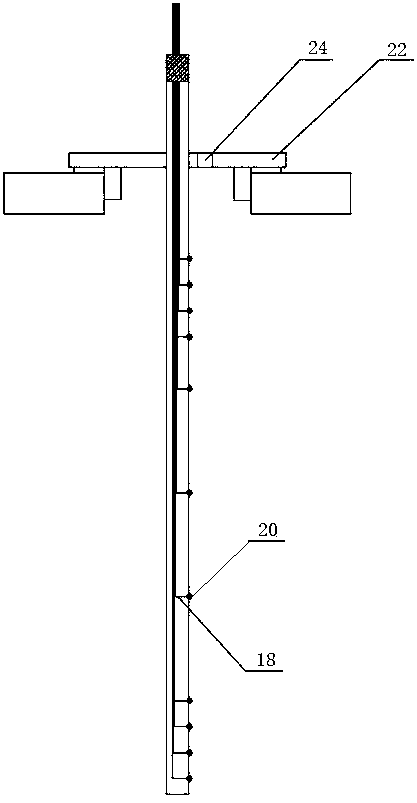

[0073] Such as figure 1 As shown, the experimental device for the heat and mass transfer process of the floating roof crude oil storage tank includes an experimental tank 1 and a preheating tank 8, and the experimental tank 1 is connected to the preheating tank 8 through a screw pump. The experimental tank 1 is designed according to the structural characteristics of the actual floating roof storage tank. The height-diameter ratio is designed according to the height-diameter ratio of the real floating roof storage tank. It is the main equipment for the static storage of crude oil, commissioning and oil delivery process experiments. The floating roof is equipped with a temperature-controlled water bath interlayer, and the first constant temperature water bath 2 is connected to the floating roof water inlet 3 (that is, the water bath interlayer water inlet) and the floating r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com