Universal tester for testing fire work equipment

A technology for pyrotechnic devices and testers, which is applied to measuring devices, instruments, measuring electrical variables, etc., can solve the problems of low safety, poor versatility and compatibility, and large measurement errors, and achieves improved safety and data resolution. High, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

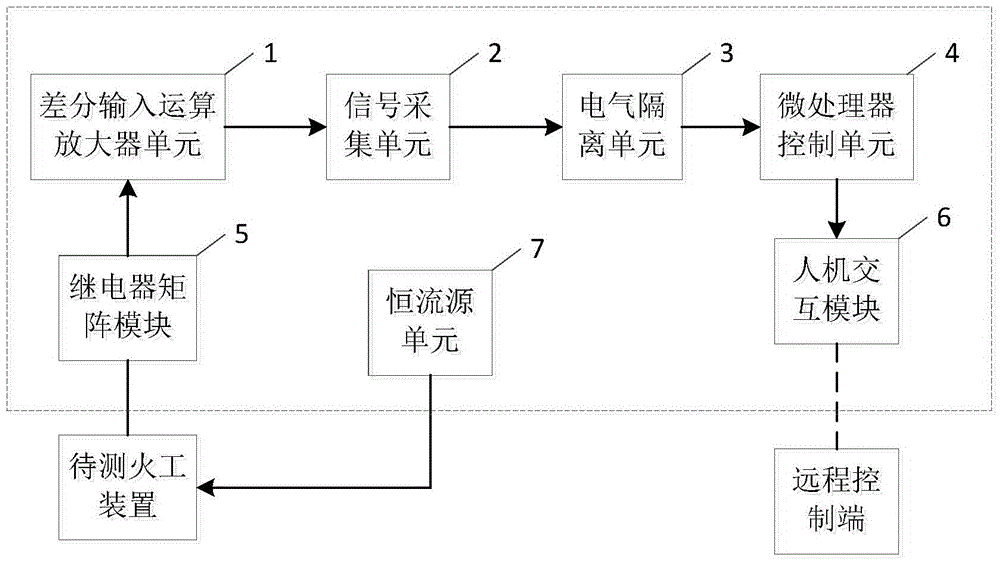

[0029] Such as figure 1 As shown, the general tester for pyrotechnic devices provided in this embodiment includes a differential input operational amplifier unit 1, a signal acquisition unit 2, an electrical isolation unit 3, a microprocessor control unit 4, a relay matrix module 5, and a human-computer interaction module 6 and constant current source unit 7.

[0030] The differential input operational amplifier unit 1 is electrically connected to the signal acquisition unit 2 , the electrical isolation unit 3 , the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com