Internal defect detection system and method for basin-type insulator of gas insulated switchgear (GIS)

A gas-insulated combination and basin-type insulator technology, which is applied in the fields of instruments, measuring electricity, measuring devices, etc., can solve the problems of component damage, acquisition of discharge signals, and low image contrast, and achieves improved stability, high detection accuracy, and false disconnection. rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

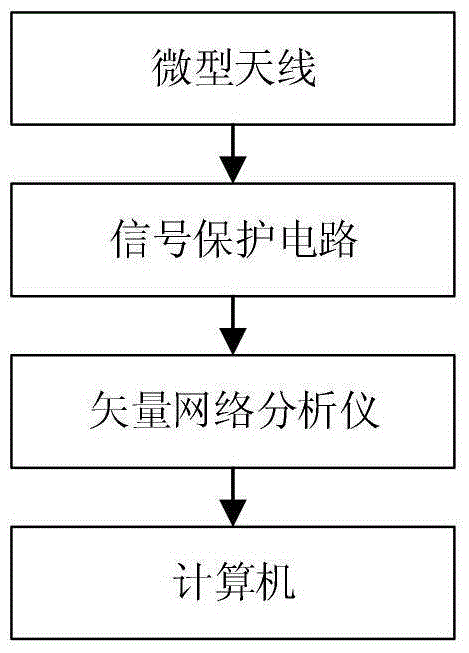

[0029] Such as figure 1 As shown, a detection system for the internal defects of the basin insulator of gas-insulated combined electrical appliances, including a miniature antenna arranged in the basin-type insulator of gas-insulated combined electrical appliances, a signal protection circuit, parameter detection equipment and a detection and analysis module installed a computer; one end of the parameter detection equipment is connected to the micro-antenna through the signal protection circuit, and the other end is connected to a computer equipped with a detection and analysis module.

[0030] The parameter detection device is a vector network analyzer.

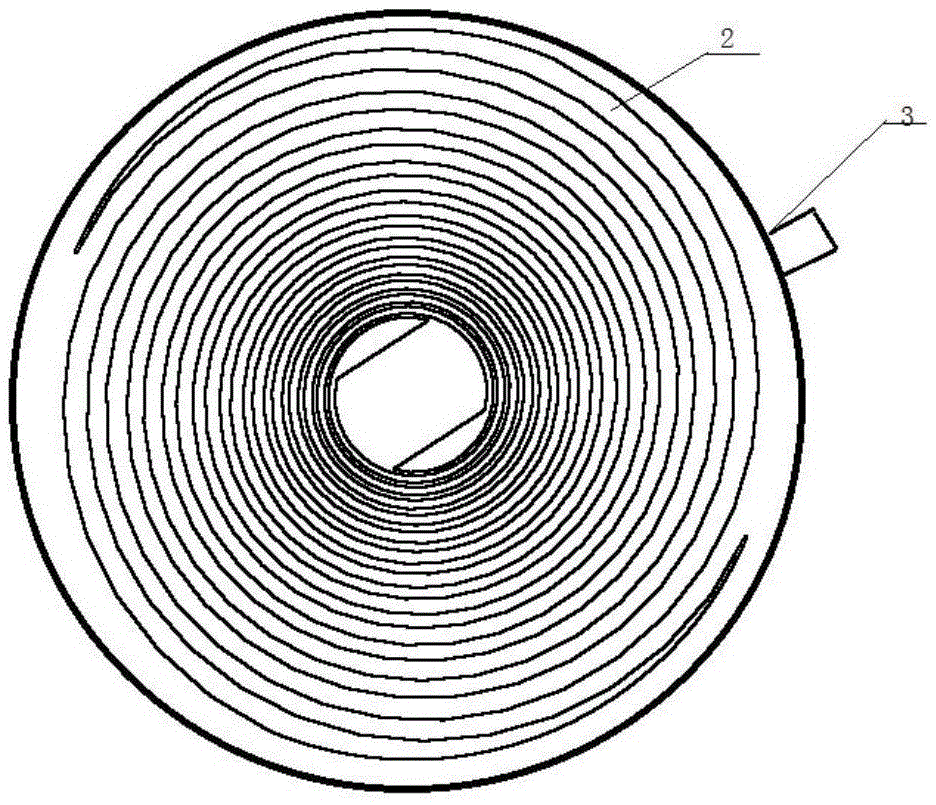

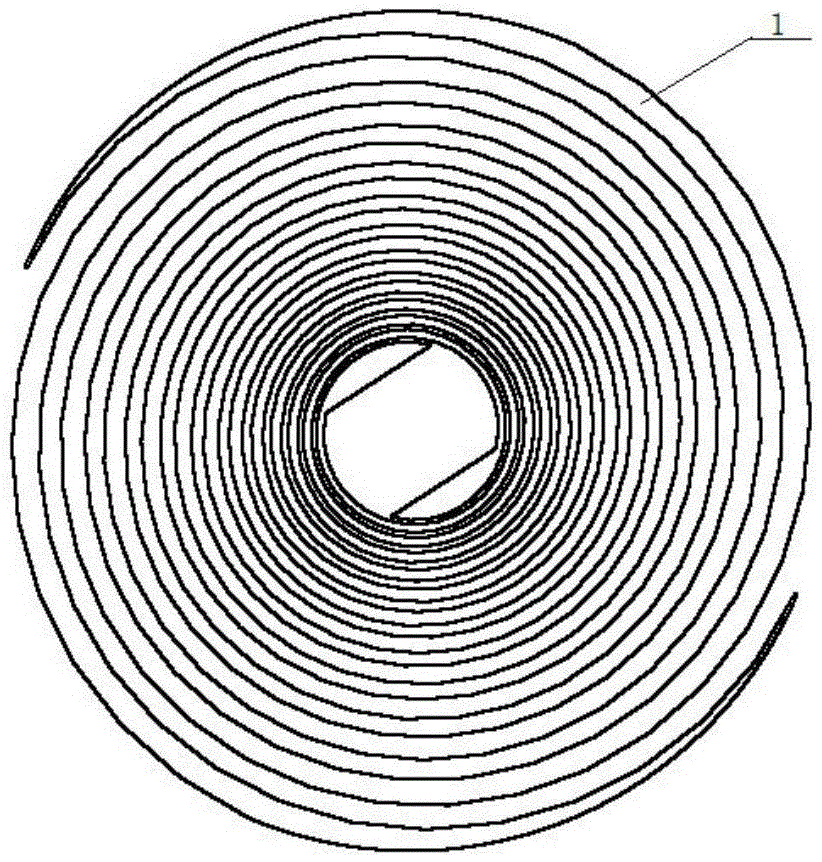

[0031] Such as figure 2 As shown, the micro-antenna is set inside the single-phase single-box pot insulator, and the micro-antenna is a logarithmic curved surface helical antenna, such as image 3 shown.

[0032] Such as Figure 4 As shown, the signal protection circuit includes a signal isolation circuit 4N25, a transi...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the micro-antenna is arranged inside the three-phase common box-type pot insulator, and the micro-antenna is composed of three curved surface loop antennas, as Figure 5 shown.

Embodiment 3

[0053] A detection method for the internal defect detection system of the basin-type insulator of the gas-insulated combined electrical appliance, comprising the following specific steps:

[0054] Step 1: Calculation of impedance correlation coefficient: the impedance correlation coefficient r xy The calculation method is:

[0055] r x y = Σ i = 1 n ( x i - x ‾ ) ( y i - y ‾ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com