Power generation process control system fault detection method

A process control system and fault detection technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve the problems of high dependence on data mean information, algorithm non-convergence, and high initial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

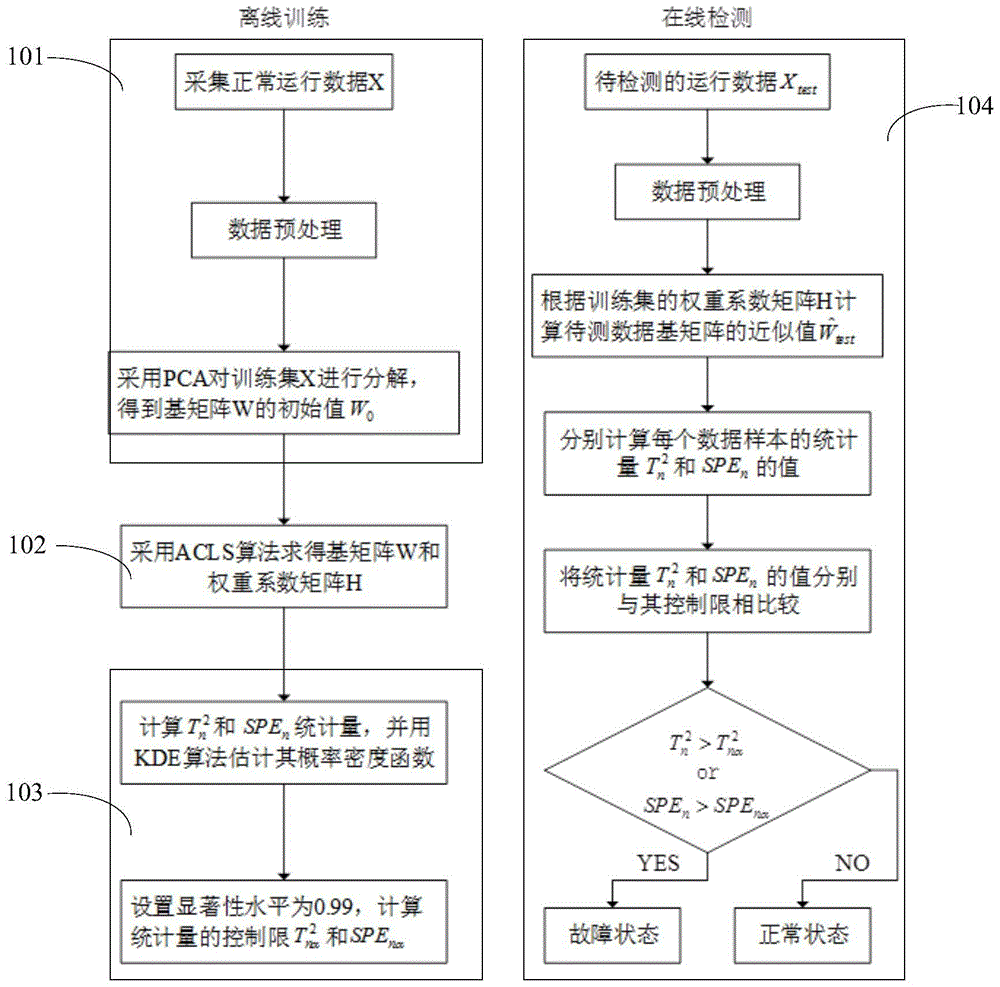

[0031] The invention provides a fault detection method for a power generation process control system based on non-negative matrix decomposition, which uses OPC communication to connect with SIS, obtains real-time or historical operation data of power generation process from SIS database or performs secondary development in SIS station All functions of the method can be realized, and its flow chart is as follows figure 1 shown, including the following steps:

[0032] Step 101, use PCA to decompose the training matrix X after noise reduction and standardization processing, and use the score matrix T as the initial value W of the base matrix W 0 ;

[0033] Step 102, iteratively solving the base matrix W and the weight coefficient matrix H of X with the Alternating Least-squares method (ALS, Alternating Least-squares) with non-negative constraints;

[0034] Step 103, constructing monitoring statistics based on non-negative matrix factorization and SPE n , using Kernel Density...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com