Polymerizable monomer, polymer compound, photocurable resin composition, sealing element for liquid crystal display element, vertical conduction material, and liquid crystal display element

A technology for liquid crystal display elements and polymer compounds, which is applied in the field of polymer compounds and can solve problems such as liquid crystal pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~17、 comparative example 1

[0201] According to the mixing ratio recorded in Tables 1 and 2, a planetary mixer (manufactured by Thinky Co., Ltd., "あわとり Taro") After mixing each material, the sealing compound for liquid crystal display elements of Examples 1-17 and Comparative Example 1 was prepared by mixing using a three-roll machine further.

[0202]

[0203] The following evaluation was performed about each sealing compound for liquid crystal display elements obtained by the Example and the comparative example. The results are shown in Tables 1 and 2.

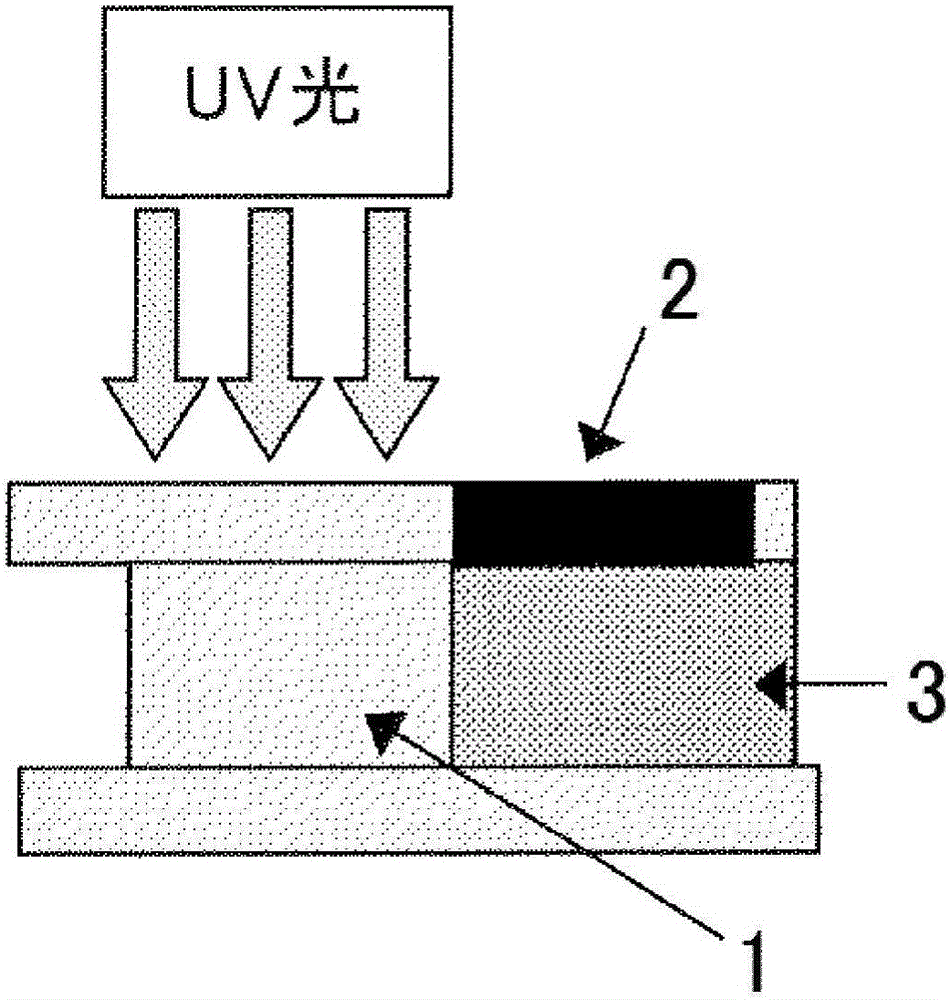

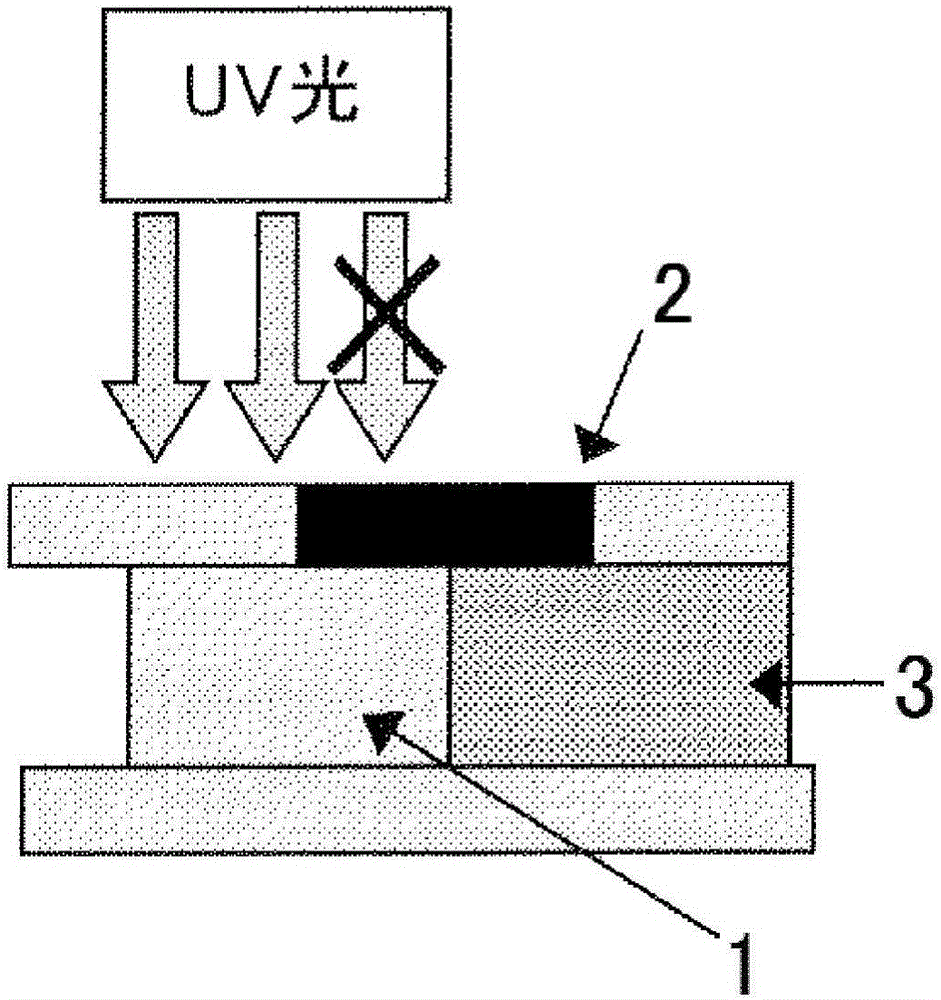

[0204] (photocurable)

[0205] Each of the sealants for liquid crystal display elements obtained in Examples and Comparative Examples was coated on a glass substrate so that the gap after bonding the glass substrates was about 5 μm, and a glass substrate of the same size was stacked on the substrate, and then, using Metal halide lamp irradiation 100mW / cm 2 Ultraviolet light (wavelength 365nm) for 10 seconds. Photocurability was evaluated by meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com