Low-alkaline rice tofu and preparation method thereof

A technology of rice tofu and beans, applied in the field of low-alkali rice tofu and its preparation, can solve the problems of deep color, heavy alkali taste, bitter taste, etc., achieve high elasticity, improve nutritional value, and reduce product pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: a kind of low-alkali rice tofu, its processing method is:

[0035] (1) Raw material screening: select indica rice to remove impurities and unsaturated particles.

[0036] (2) Soaking: Take 100g of indica rice, wash it, add water and soak it for 4-6 hours.

[0037] (3) Refining: Drain the indica rice, add 200ml of clear water, 0.3g of CaO, 5g of potato starch, and 6g of corn modified starch, mix well, and grind into rice milk.

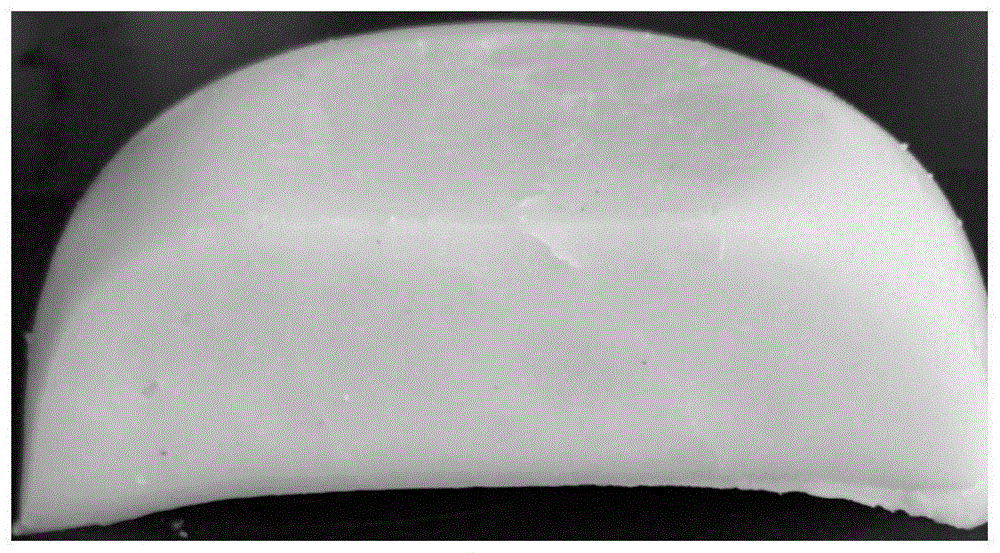

[0038] (4) Steaming: put the above-mentioned rice milk in a heating container and steam for 40 minutes on medium heat. Since the starch is easy to precipitate, it needs to be stirred evenly in the early stage of steaming until the rice milk is thick and difficult to stir.

[0039] (5) Molding: cooling and molding after steaming to make low-alkali rice tofu.

Embodiment 2

[0040] Embodiment 2: a kind of low-alkali rice tofu, its processing method is:

[0041] (1) Raw material screening: select indica rice to remove impurities and unsaturated particles.

[0042] (2) Soaking: Take 100g of indica rice, wash it, add water and soak it for 4-6 hours.

[0043] (3) Refining: Drain the indica rice, add 220ml of water, 0.3CaO, 5g of potato starch, and 6g of corn modified starch, mix well, and grind into a fine rice slurry.

[0044] (4) Stew: Put a little water in the pot, heat it to boiling, then put in the ground rice milk, heat it with medium heat for about 5 minutes, then change to low heat, stir continuously in the early stage of cooking, and cook for about 40 minutes .

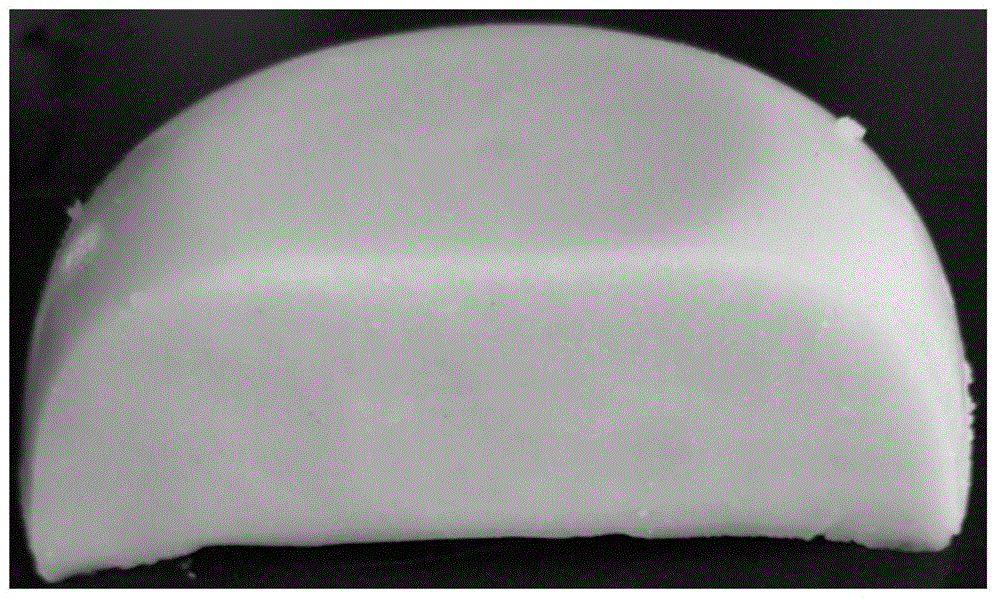

[0045] (5) Molding: boil the pulp and then cool and shape it to make low-alkali rice tofu.

Embodiment 3

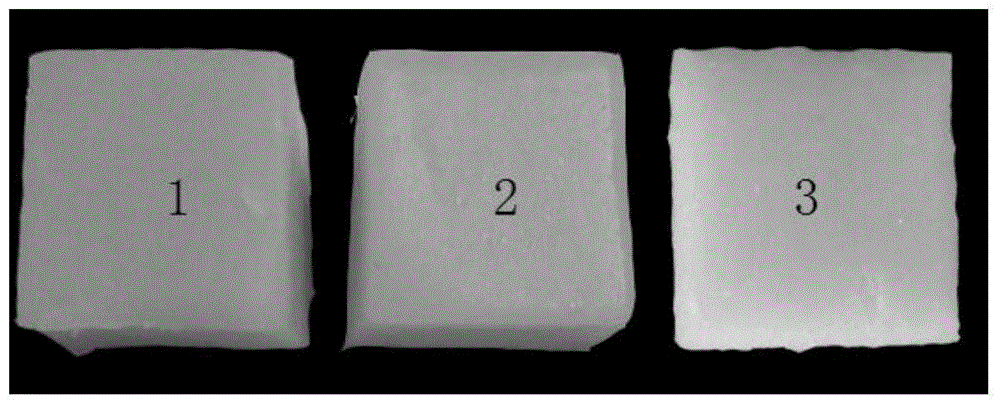

[0046] Embodiment 3: the comparison of low-alkali rice tofu and non-alkali rice tofu and traditional rice tofu

[0047] The recipes of the four kinds of rice tofu are as follows:

[0048] The formula (weight ratio) of table 1 rice bean curd

[0049] Variety

[0050] Its processing method is:

[0051] (1) Raw material screening: select indica rice to remove impurities and unsaturated particles.

[0052] (2) Soaking: Take 100g of indica rice, wash it, add water and soak it for 4-6 hours.

[0053] (3) Refining: Drain the indica rice, add the required ingredients into the drained rice according to the formula in Table 1, mix well, and grind into fine rice slurry.

[0054] (4) Stew: Put a little water in the pot, heat it to boiling, then put in the ground rice milk, heat it with medium heat for about 5 minutes, then change to low heat, stir continuously in the early stage of cooking, and boil for about 40 minutes ,take out.

[0055] (5) Molding: After boiling the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com