High-strength separating membrane with reinforcing material and preparation method of high-strength separating membrane

A technology for reinforcing materials and separation membranes, applied in semipermeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problem of weak combination of separation membrane and support tube, separation membrane and support tube peeling, and restriction of the service life of the separation membrane, etc. problems, to achieve the effect of easy industrial scale-up, wide adjustment range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

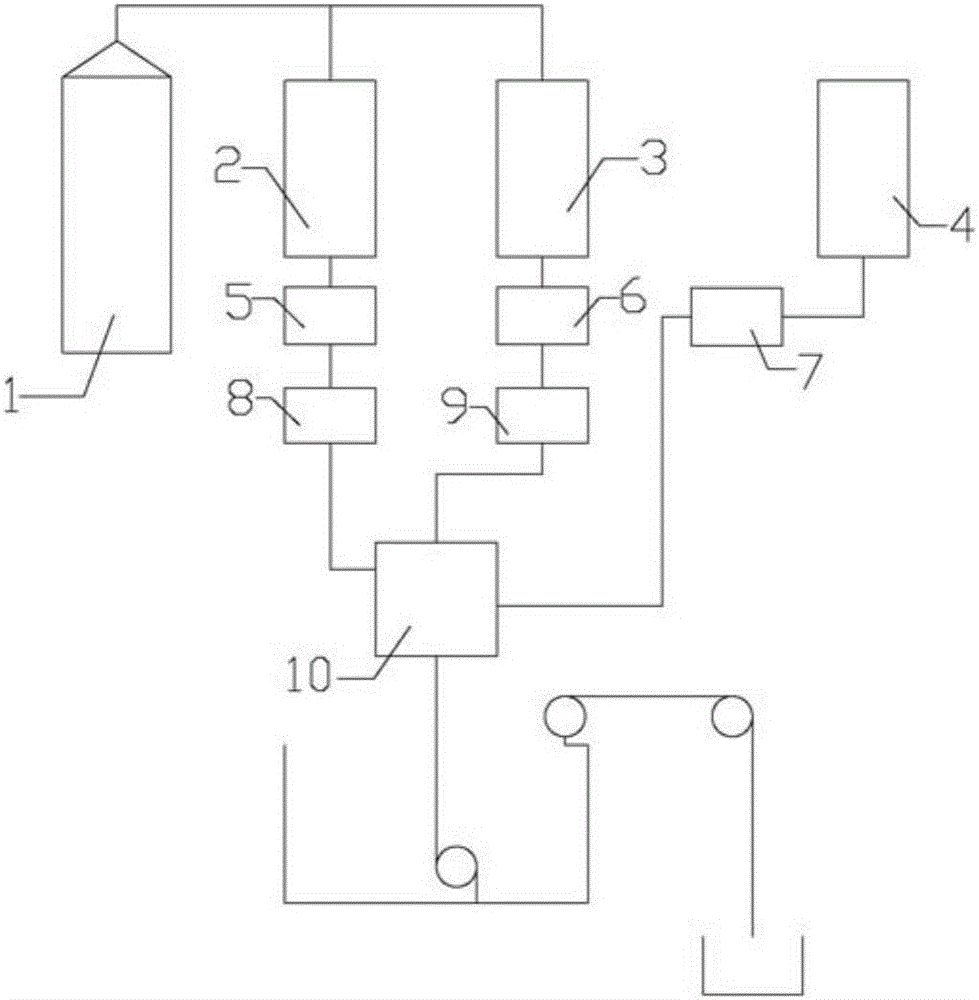

[0042] A preparation method of a high-strength separation membrane with a reinforcing material, the preparation method comprising the steps of:

[0043] ①Add 20g of polyvinylidene fluoride and 8g of PEG-600 to 72g of DMAc, mechanically stir at 80°C for 12h, filter, stand still for 6h, and defoam to obtain the film-making solution;

[0044] ② Blend 15g of toluene diisocyanate with 1g of calcium oxide, stir at room temperature for 12 hours, filter and stand for 6 hours, and defoam to obtain a reinforcing material;

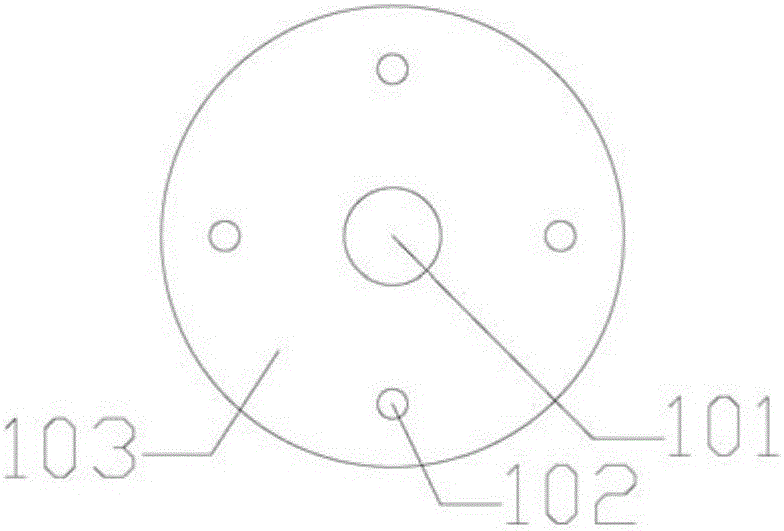

[0045] ③ will be as figure 2 The three-channel nozzle shown is heated to 80°C, and the deionized water flows out from the deionized water outlet of the three-channel nozzle through independent channels. The film-making solution is extruded at the same time, falls vertically into the gel in deionized water, is drawn after being wound by a winding wheel, and soaked in deionized water to obtain a high-strength separation membrane with reinforcing materials.

Embodiment 2

[0047] A preparation method of a high-strength separation membrane with a reinforcing material, the preparation method comprising the steps of:

[0048] ①Add 18g of polyethersulfone and 8g of PEG-200 to 74g of DMAc, mechanically stir at 80°C for 12h, filter, stand still for 6h, and defoam to obtain a membrane-forming solution;

[0049] ② Blend 19g of toluene diisocyanate with 1g of calcium oxide, stir at room temperature for 12h, filter, stand for 6h, and defoam to obtain a reinforcing material solution;

[0050] ③ will be as figure 2 The three-channel nozzle shown is heated to 80°C, and the deionized water flows out from the deionized water outlet of the three-channel nozzle through independent channels. The film-making solution is extruded at the same time, falls vertically into the gel in deionized water, is drawn after being wound by a winding wheel, and soaked in deionized water to obtain a high-strength separation membrane with reinforcing materials.

Embodiment 3

[0052] A preparation method of a high-strength separation membrane with a reinforcing material, the preparation method comprising the steps of:

[0053]① Add 20g of polysulfone and 8g of PEG-200 into 72g of DMF, mechanically stir at 80°C for 12h, filter, stand still for 6h, and defoam to obtain the membrane-forming solution;

[0054] ② Blend 19g of toluene diisocyanate with 1g of calcium oxide, stir at room temperature for 12h, filter, stand for 6h, and defoam to obtain a reinforcing material solution;

[0055] ③ will be as figure 2 The three-channel nozzle shown is heated to 80°C, and the deionized water flows out from the deionized water outlet of the three-channel nozzle through independent channels. The film-making solution is extruded at the same time, falls vertically into the gel in deionized water, is drawn after being wound by a winding wheel, and soaked in deionized water to obtain a high-strength separation membrane with reinforcing materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com