Catalytic membrane coupling system and application method thereof

A technology of coupling system and application method, applied in the field of membrane separation sewage treatment, can solve the problems of low photocatalyst quantum efficiency, base film damage, low light utilization rate, etc., so as to reduce transportation and storage costs, improve cleaning efficiency, and improve light The effect of catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

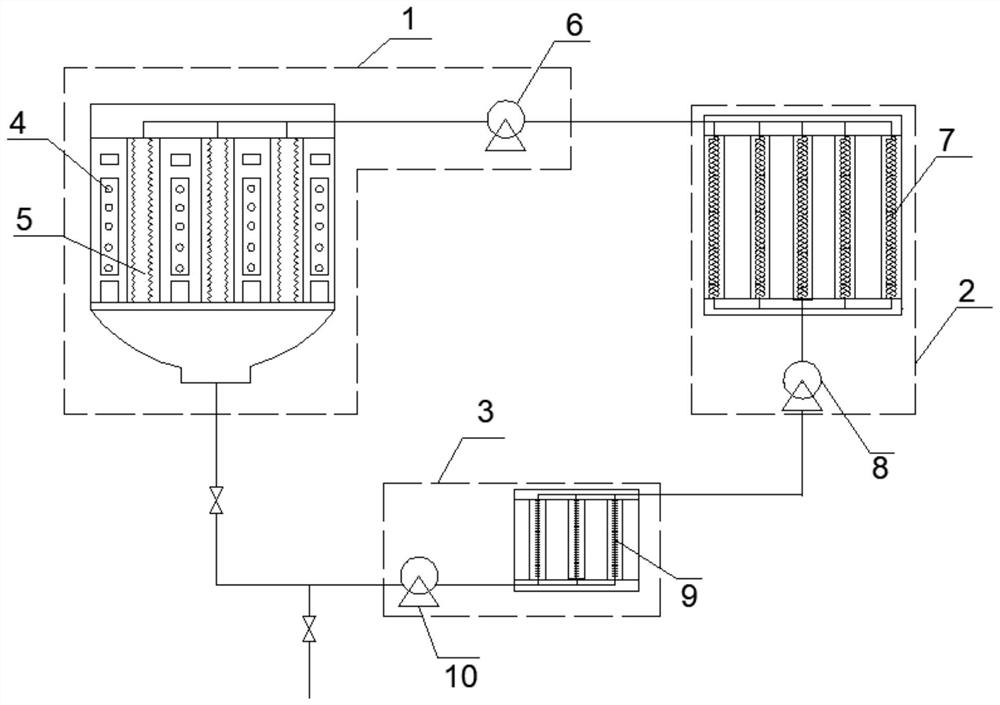

[0065] This embodiment provides a catalytic membrane coupling system, the structural schematic diagram of the system is as follows figure 1 As shown, the system includes a photocatalytic membrane unit 1 , a self-cleaning membrane unit 2 and a water regeneration unit 3 which are sequentially connected in a cycle.

[0066] The photocatalytic membrane unit 1 is provided with 4 groups of light source generating equipment 4, and a photocatalytic membrane assembly 5 is arranged between each two groups of the light source generating equipment 4, and also includes a peroxidizer connected to the photocatalytic membrane assembly 5. Hydrogen delivery device 6; The photocatalytic membrane module 5 is a flat membrane module; The light source generating device 4 is a full-band light source generating device 4; The photocatalytic film used in the photocatalytic membrane module 5 includes the first base film and Titanium dioxide loaded on the first base film, the first base film is a ceramic ...

Embodiment 2

[0070] This embodiment provides a catalytic membrane coupling system, which includes a photocatalytic membrane unit 1 , a self-cleaning membrane unit 2 and a water regeneration unit 3 which are sequentially connected in a cycle.

[0071] The photocatalytic membrane unit 1 is provided with 5 groups of light source generating equipment 4, and a photocatalytic membrane assembly 5 is arranged between each two groups of the light source generating equipment 4, and also includes a peroxidizer connected to the photocatalytic membrane assembly 5. Hydrogen delivery device 6; the photocatalytic membrane module 5 is a tubular membrane module; the light source generating device 4 is a full-band light source generating device 4; the photocatalytic film used in the photocatalytic membrane module 5 includes a first base film and a carbon nitride nanocatalyst loaded on the first base film, the first base film is a ceramic membrane DEA100 with a pore size of 0.22 μm.

[0072] The self-cleaning...

Embodiment 3

[0075] This embodiment provides a catalytic membrane coupling system, which includes a photocatalytic membrane unit 1 , a self-cleaning membrane unit 2 and a water regeneration unit 3 which are sequentially connected in a cycle.

[0076] The photocatalytic membrane unit 1 is provided with 3 groups of light source generating equipment 4, and a photocatalytic membrane assembly 5 is arranged between each two groups of the light source generating equipment 4, and also includes a peroxidizer connected to the photocatalytic membrane assembly 5. Hydrogen delivery device 6; The photocatalytic membrane module 5 is a hollow fiber membrane module; The light source generating device 4 is an ultraviolet light generating device; The photocatalytic membrane used in the photocatalytic membrane module 5 includes a first base film and a load Zinc oxide on the first base film, the first base film is a ceramic film DEB100 with a pore size of 5 μm.

[0077] The self-cleaning membrane unit 2 includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com