Powder feeding and dissolving method and tank

A technology of dissolving tank and powder, applied in the field of powder dosing and dissolving tank, can solve the problems of serious dust pollution, low work efficiency, high labor intensity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

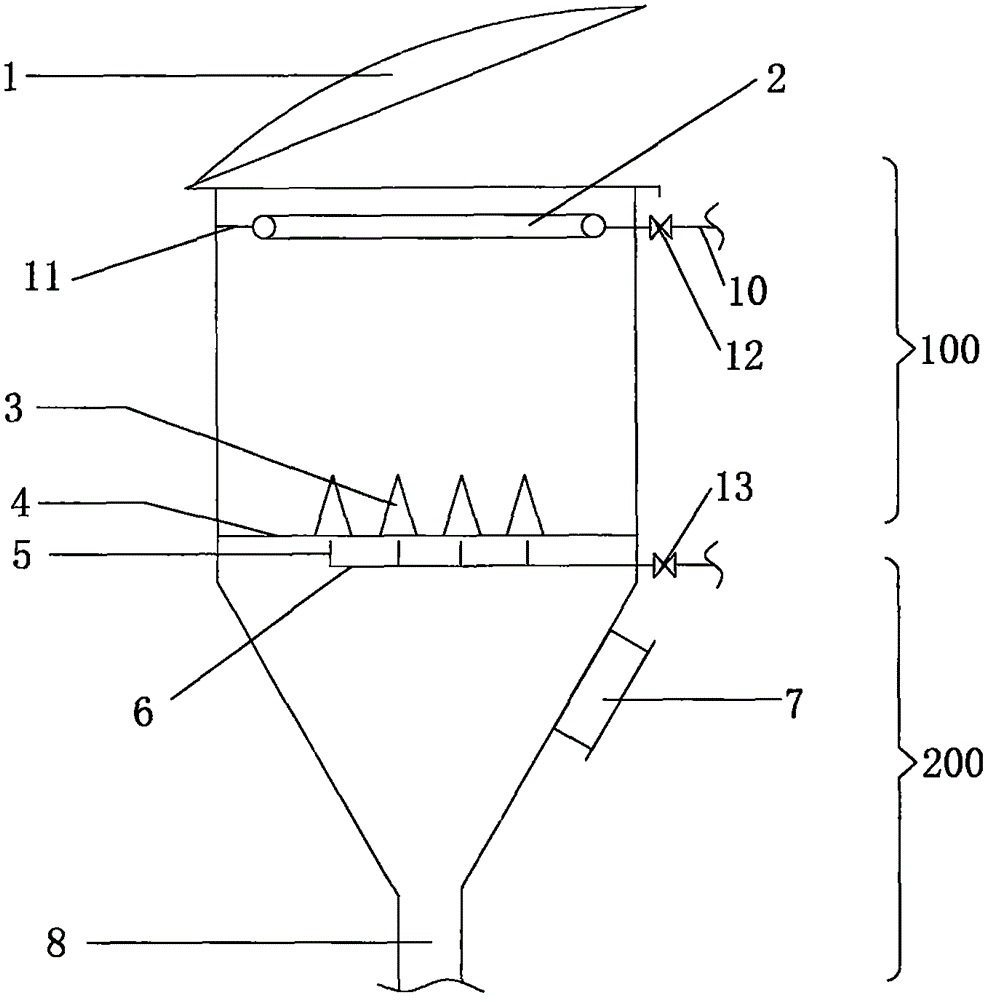

[0046] The first specific embodiment of a powder dosing and dissolving tank used to realize the above-mentioned powder dosing and dissolving method in the present invention is as follows: Figure 1 to Figure 5 .

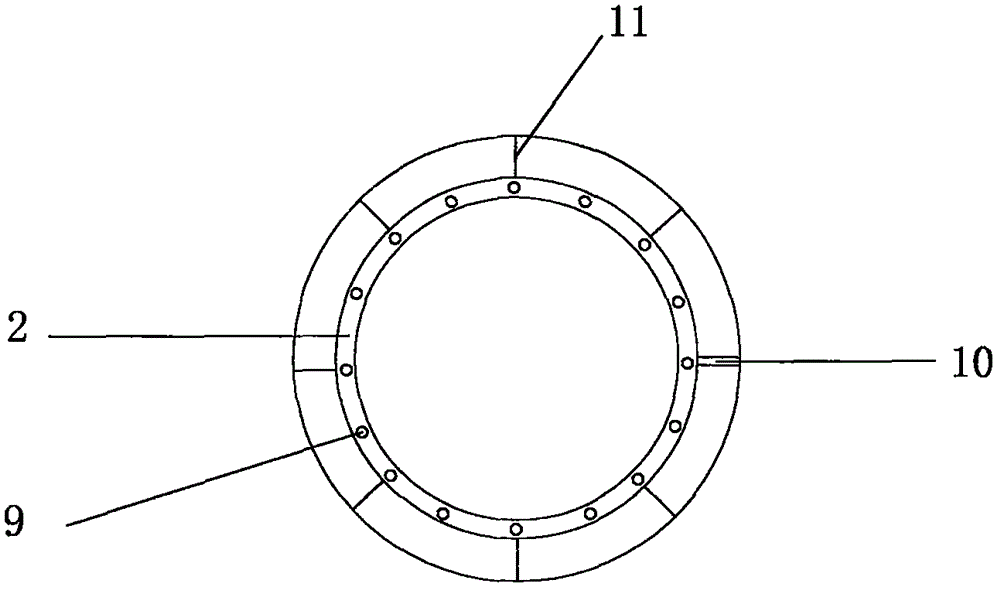

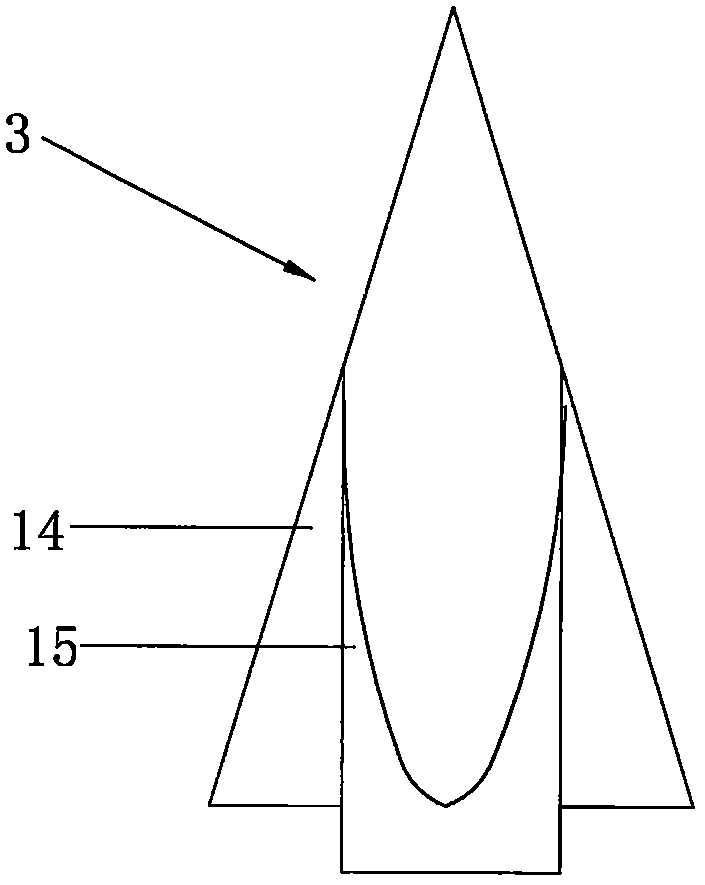

[0047] Such as figure 1 As shown, a powder dosing and dissolving tank is mainly composed of an upper cylindrical shell part (100) and a lower conical shell part (200). The top of the cylindrical shell part (100) is provided with a top cover (1), the upper part of the inner wall is provided with an annular spray device (2), the lower part of the inner wall is provided with a grate plate (4), and a plurality of bag breakers (3) are fixed in the center of the upper surface of the grate plate (4), and the lower plate of the grate plate A liquid inlet pipe (6) is fixed on the surface, and a liquid inlet pipe control valve (13) is installed on the liquid inlet pipe (6). There is a branch pipe (5) of the liquid inlet pipe (6) below each bag breaker (3). ), which can spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com