Cross-shaped orthogonal compound drive piezoelectric pipe-shaped transducer

A cross-shaped, electric tube-shaped technology, applied in the field of cross-shaped orthogonal composite drive piezoelectric tube-shaped transducers, can solve the problems of weak radial ultrasonic radiation intensity, achieve good fixing effect, increase power density, and enhance diameter effect on stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

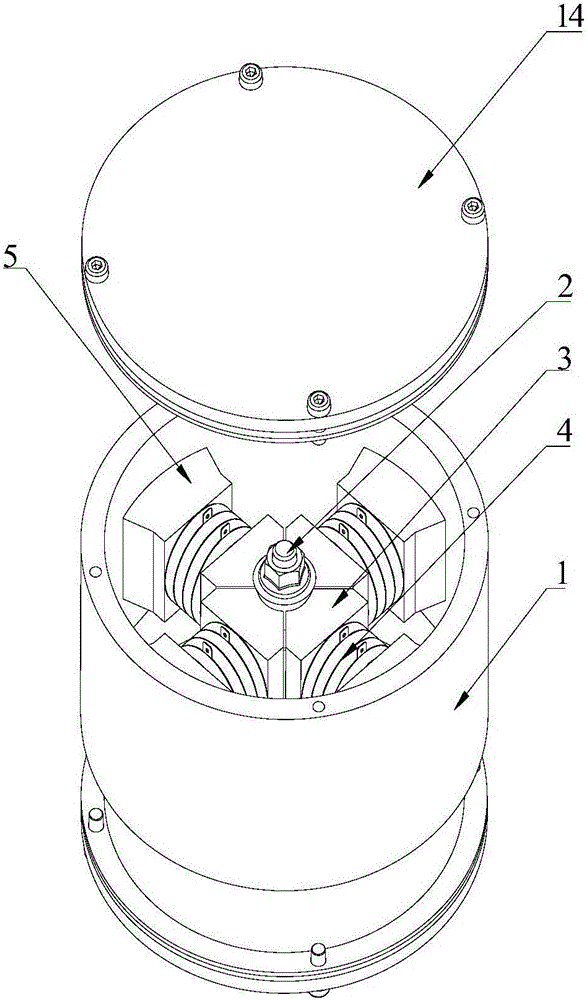

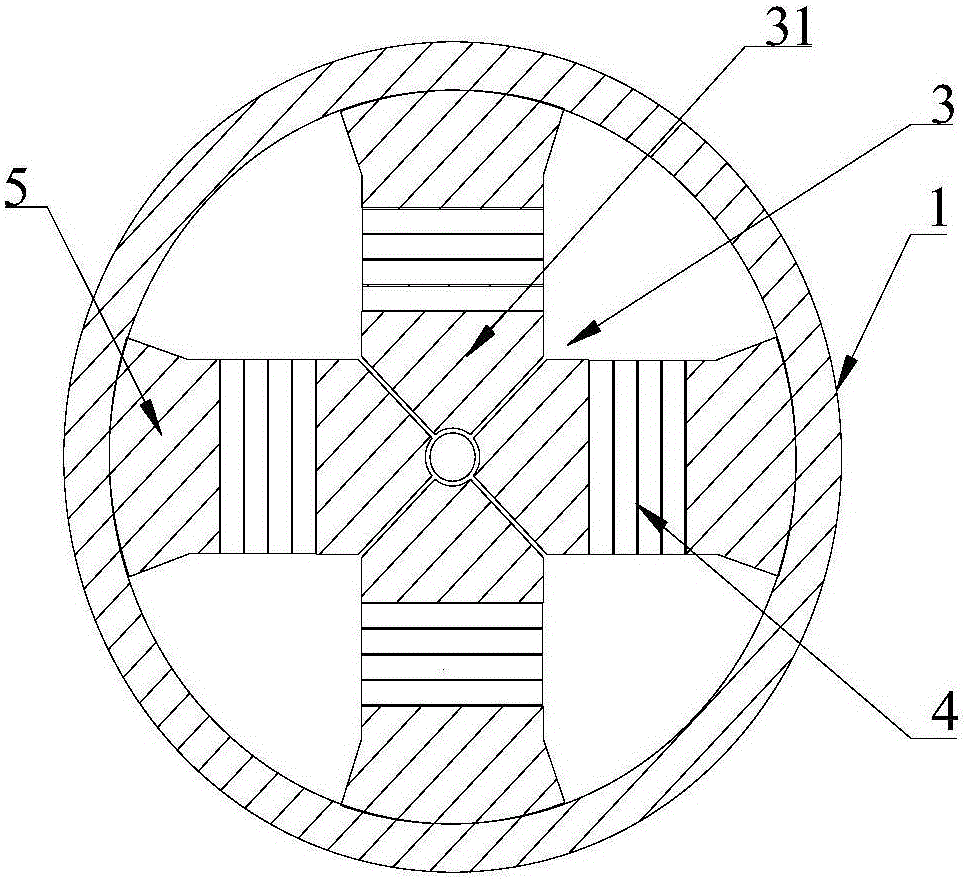

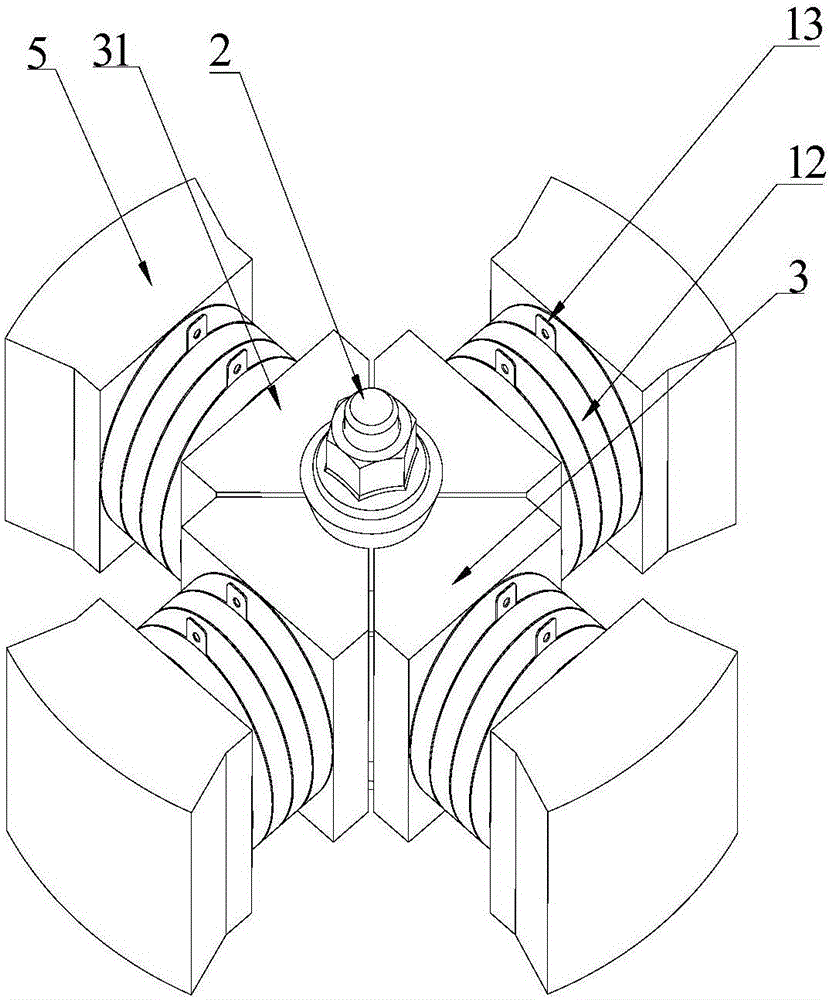

[0054] like Figure 1-8 As shown, in this embodiment, a cross-shaped orthogonal compound-driven piezoelectric tubular transducer is provided, and the cross-shaped orthogonal compound-driven piezoelectric tubular transducer includes a cross-shaped orthogonal compound sandwich piezoelectric An excitation source and a cylindrical radial radiation shell 1; the radial radiation shell 1 is set outside the cross-orthogonal composite sandwich piezoelectric excitation source;

[0055] The cross-orthogonal composite sandwich piezoelectric excitation source includes a conical prestressed elastic expansion structure 2, a cross-shaped orthogonal composite central mass 3, four groups of piezoelectric ceramic crystal stacks 4 with the same structure and four outer shells with the same shape. mass block 5;

[0056] The cross-shaped orthogonal composite central mass 3 includes four components 31 of the same shape, and the four components 31 are placed symmetrically in the center; four groups ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com