Method for calculating alloy droplet deposition cooling rate

A technology of cooling rate and calculation method, applied in the field of 3D printing process, can solve problems such as cost increase, achieve the effect of saving materials, optimizing 3D printing process and parameters, and increasing the degree of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

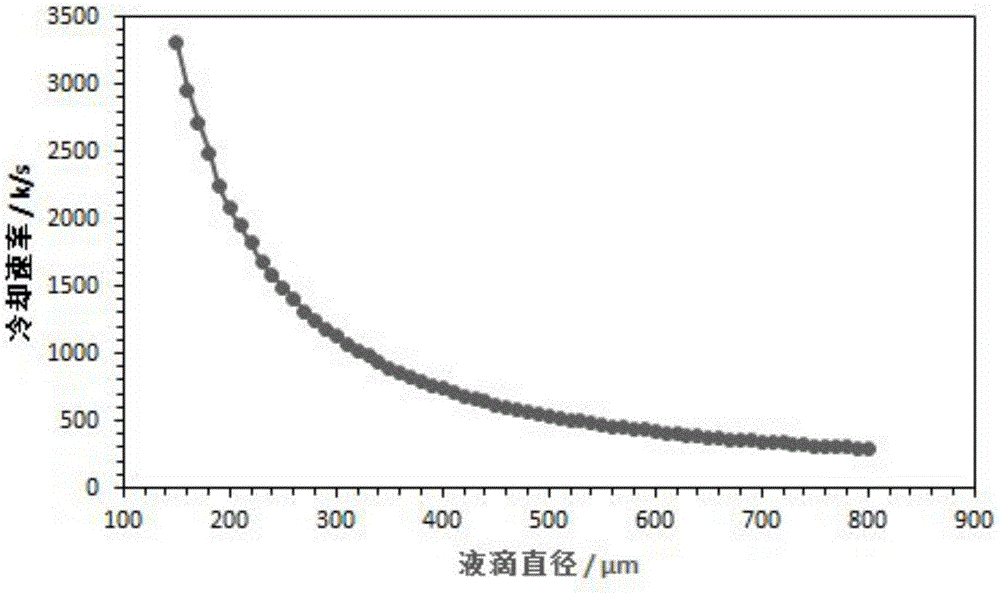

[0027] Step 1. Select CuSn6 alloy as the experimental material. Based on the uniform droplet 3D printing process and material parameters, adjust the process parameters and injection conditions to prepare alloy droplets with different particle sizes and uniform distribution. The alloy droplets are ejected and pass through the movement path Natural cooling, each alloy droplet cools naturally and solidifies into tiny particles, which are collected for metallographic sample preparation.

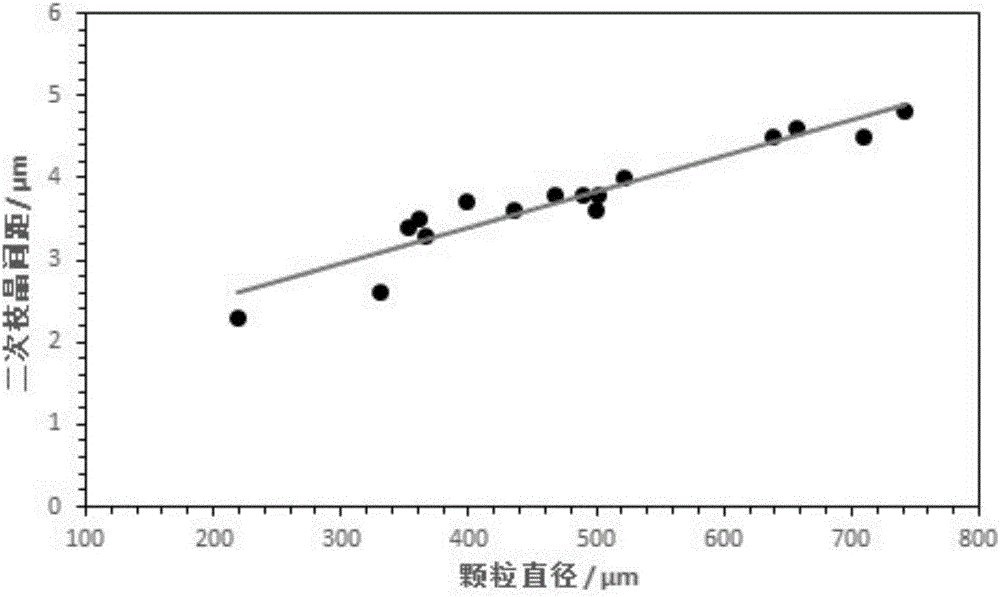

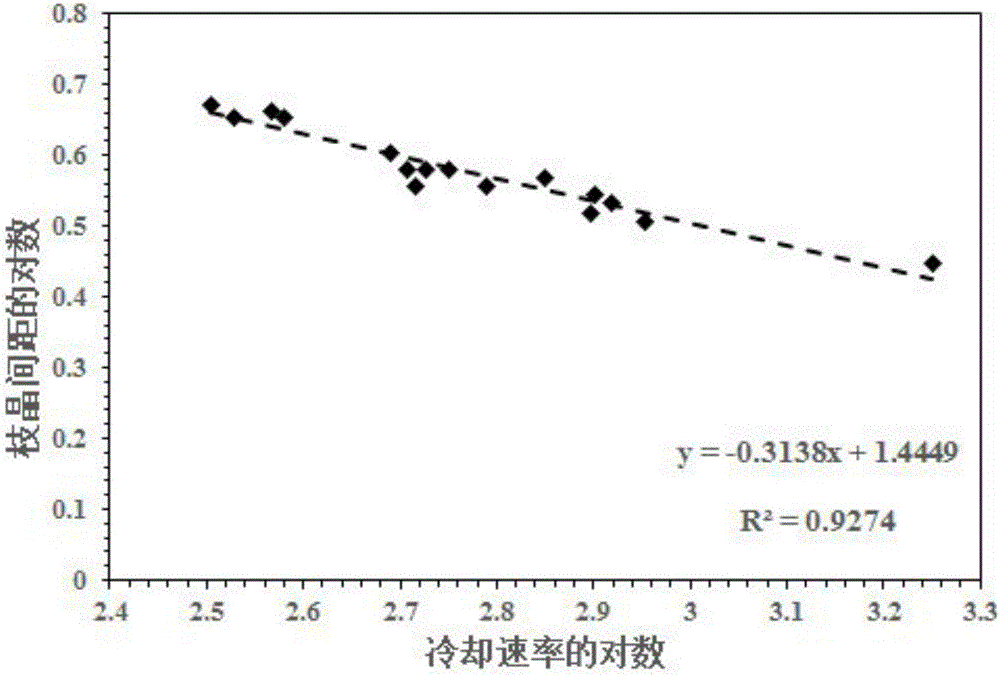

[0028] Step 2. Carry out sample inlay on CuSn6 alloy particles with different particle sizes in turn, use ethanol + hydrogen peroxide as the corrosion solution to corrode, use an optical microscope to observe the dendrite structure, and measure n≧40 groups twice for any droplet size Dendrite spacing, and measure the total length l, according to the relationship between the secondary dendrite spacing Calculate the secondary dendrite spacing value of the alloy droplet corresponding to the particle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com