Drill bit special for carbon fiber composite

A composite material and carbon fiber technology, which is applied in the direction of drill repair, twist drill, drilling tool accessories, etc., can solve the problems of fiber scattering, burning attachments and burrs, easy delamination, etc., to avoid delamination, efficient chip breaking and Chip removal function, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

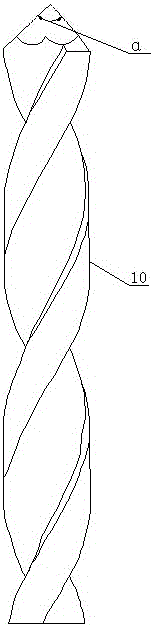

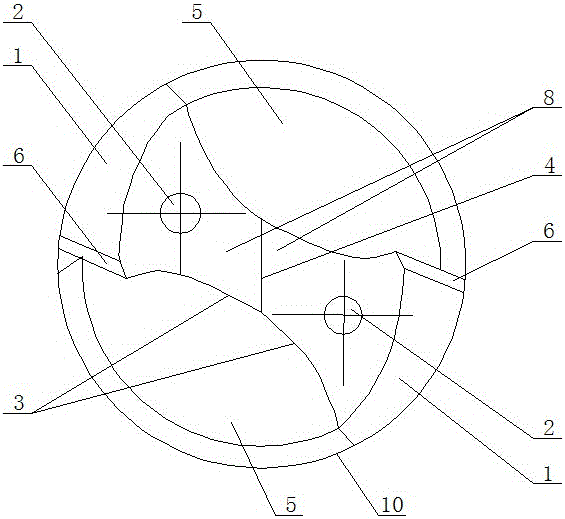

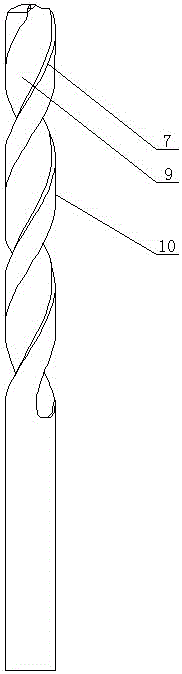

[0018] Specific implementation one: as Figure 1~Figure 4 As shown, this embodiment discloses a special drill bit for carbon fiber composite materials, including a drill bit main body 10, and the outer circumferential surface of the drill bit main body 10 is axially machined with two spiral grooves 5. The two spiral grooves 5. The direction of rotation is the same, and the flank 1 arranged on the conical surface of the head of the drill main body 10 is divided into two by two flat grooves 8, and the axial cross-sections of the two flat grooves 8 are arc-shaped, The junction of the two flat grooves 8 is a raised chisel edge 4, the chisel edge 4 is arranged at the center of the head of the drill main body 10, and the two flat grooves 8 are symmetrically arranged with respect to the chisel edge 4; The rake face 9 and the flank face 1 at the helical groove 5 of the drill main body 10 are connected by a chamfer (that is, the rake face 9 and the flank face 1 are separated by the cha...

specific Embodiment approach 2

[0023] Specific implementation two: as figure 1 and figure 2 As shown, in the special drill bit for carbon fiber composite materials according to the first embodiment, the included angle between the two flank surfaces 1 located on the generatrix of the same axial section is α, and α=90°.

[0024] The included angle α=90° between the two said flank faces 1 located in the same axial section of the generatrix, which is different from the 140° drill tip angle used by general solid carbide drills, can effectively avoid the occurrence of drilling. Delamination and burr phenomena.

specific Embodiment approach 3

[0025] Specific implementation three: as Figure 1~Figure 4 As shown, in the special drill bit for carbon fiber composite material according to the first embodiment, the secondary cutting edge 7 arranged on the outer edge of the side wall of the spiral groove 5 of the drill bit main body 10 forms an included angle of 45° with the flank 1 . Here are common structural parameters designed for the manufacturing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com