Crystal silicon cell piece welding device and string welding machine with crystal silicon cell piece welding device

A technology for crystalline silicon cells and welding devices, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve problems such as difficulty in adapting to crystalline silicon cells, decrease in welding yield rate, cracks, etc., to prevent secondary damage and improve good products. The effect of high efficiency and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

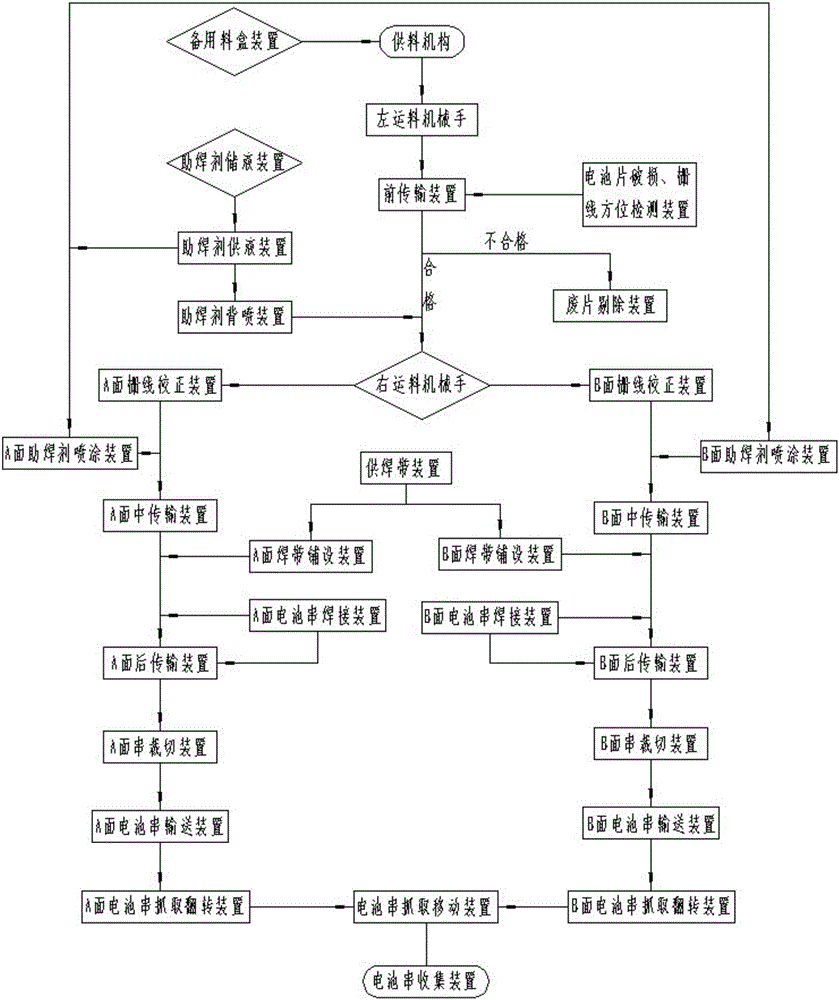

[0038] In order to facilitate those skilled in the art to better understand the essence of the present invention, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

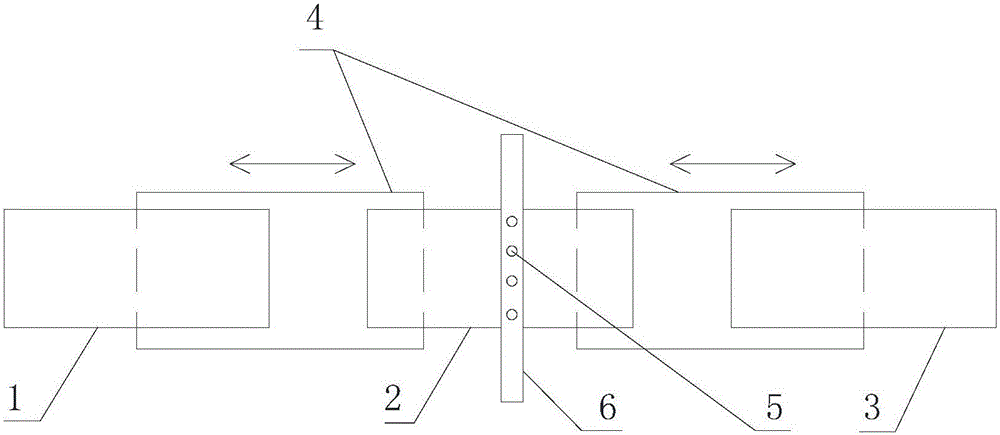

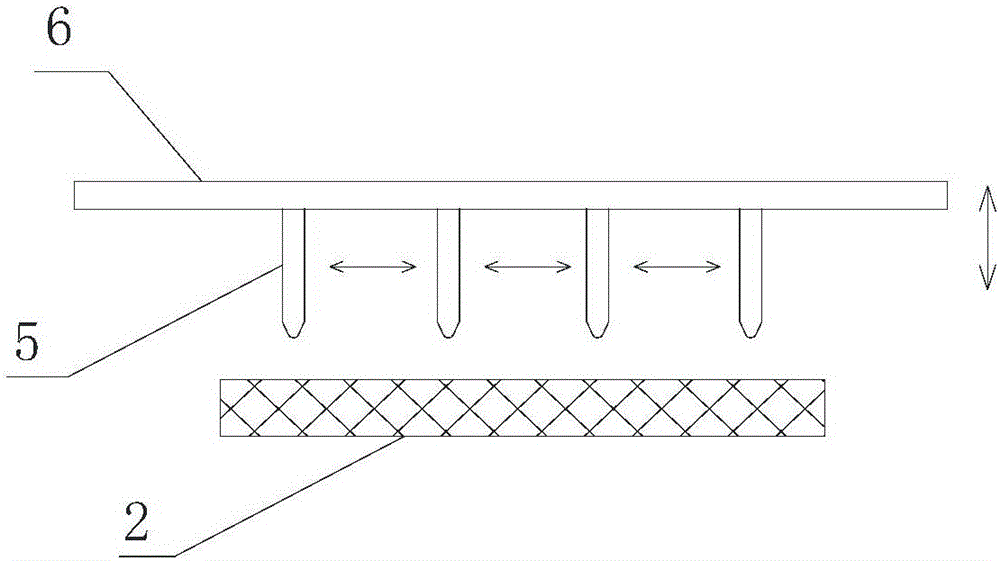

[0039] Such as figure 1 , figure 2 As shown, a crystalline silicon cell welding device is characterized in that it includes: a preheating station 1, a welding station 2, a cooling station 3, a moving mechanism 4 and several groups of welding heads 5 that can move up and down, and the moving mechanism 4 It is used to realize the station transfer of crystalline silicon cells between the preheating station 1, the welding station 2 and the cooling station 3, and the welding head 5 is used to realize the welding of the ribbon.

[0040] Wherein, the preheating table 1 is divided into three sections of preheating areas, and the preheating temperatures of the three sections of preheating areas are respectively: 30±5°C, 60±5°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com