Laser black marking method of automatic production line

An automatic production line, black technology, applied in the field of laser black marking, can solve the problems of low contrast, large ink consumption, difficult to identify, etc., to achieve high recognition rate, improve quality, and enhance the effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

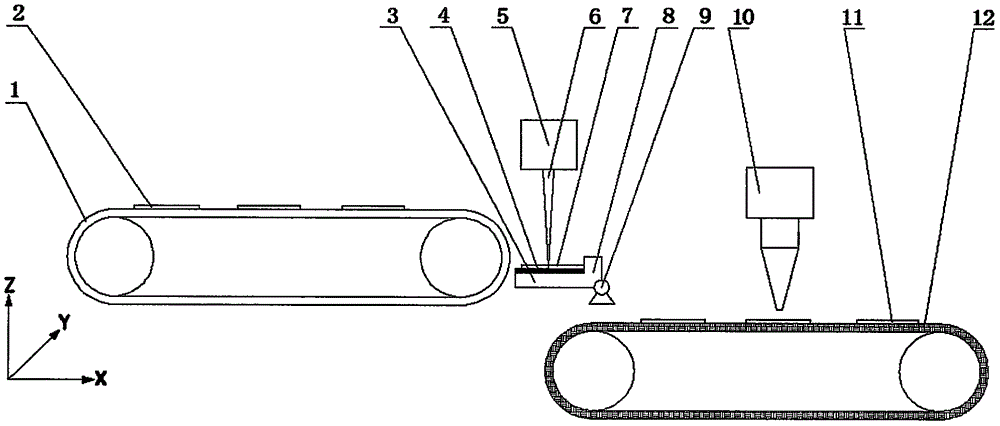

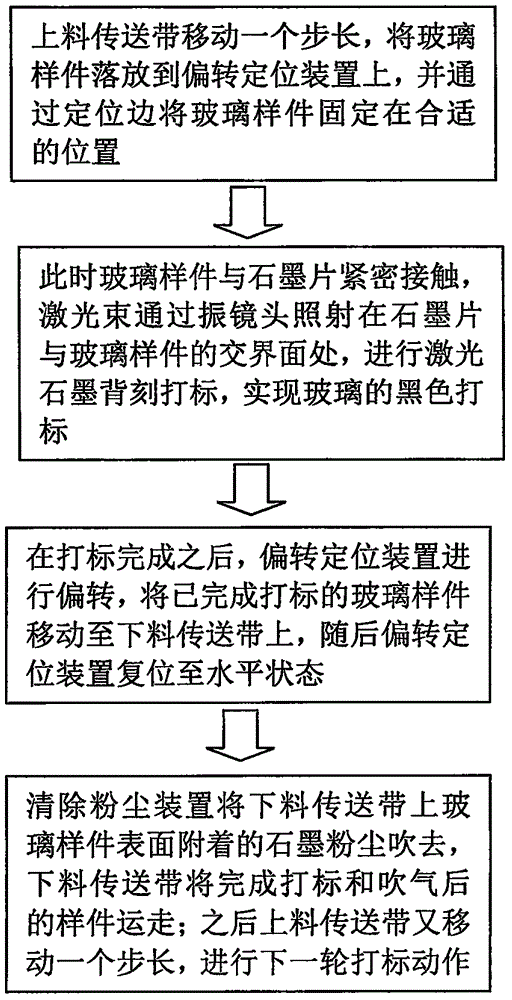

[0020] The laser black marking method of a kind of automatic production line of the present invention comprises the following steps:

[0021] 1) The feeding conveyor belt 1 transports the glass sample 2 to be processed;

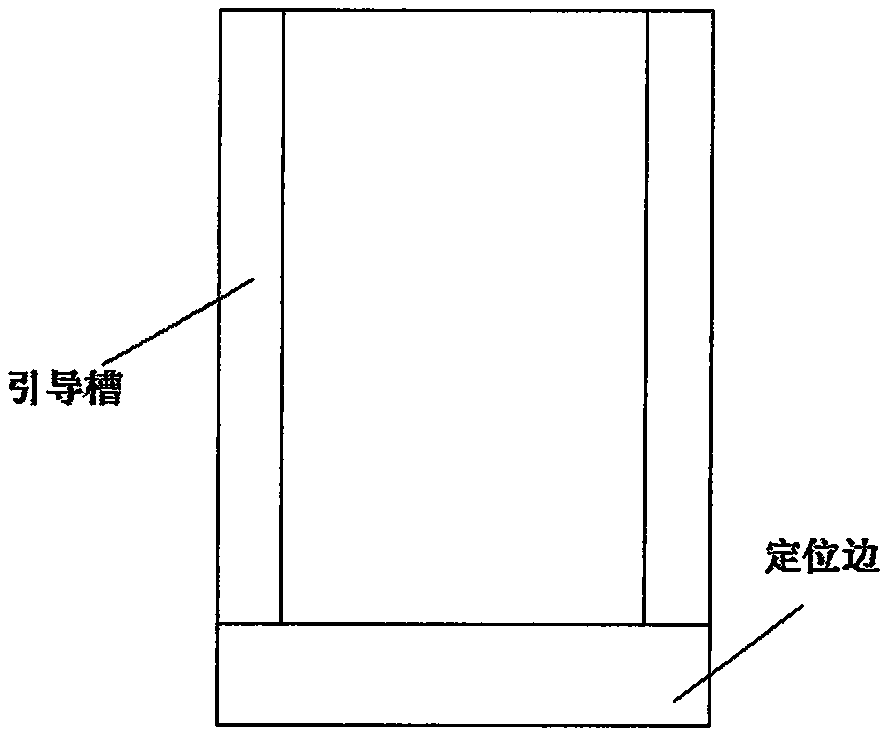

[0022] 2) deflect the glass sample 2 to be processed above the positioning device 3, and accurately position the glass sample 2 to be processed by the positioning edge 8, so that the glass sample 2 to be processed is in close contact with the graphite sheet 4;

[0023] 3) irradiating the laser beam 6 on the contact surface between the glass sample 2 to be processed and the graphite sheet 4;

[0024] 4) Under the action of the laser beam 6, the graphite sheet 4 is violently ablated, and an instantaneous high temperature and high pressure is formed between the graphite sheet 4 and the glass sample 7 being processed, and the graphite sheet 4 is violently ablated on the glass sample being processed. A deposition layer is formed on the glass sample 7, and the dep...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap