Laser preparing method of glass black markers

A laser and black technology, applied in the field of laser preparation of glass black marking, can solve the problems of non-corrosion resistance, high cost, durability and stability limitations of marking, and achieve low marking cost, strong stability and durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] The invention is a laser preparation method for glass black marking, comprising the following steps:

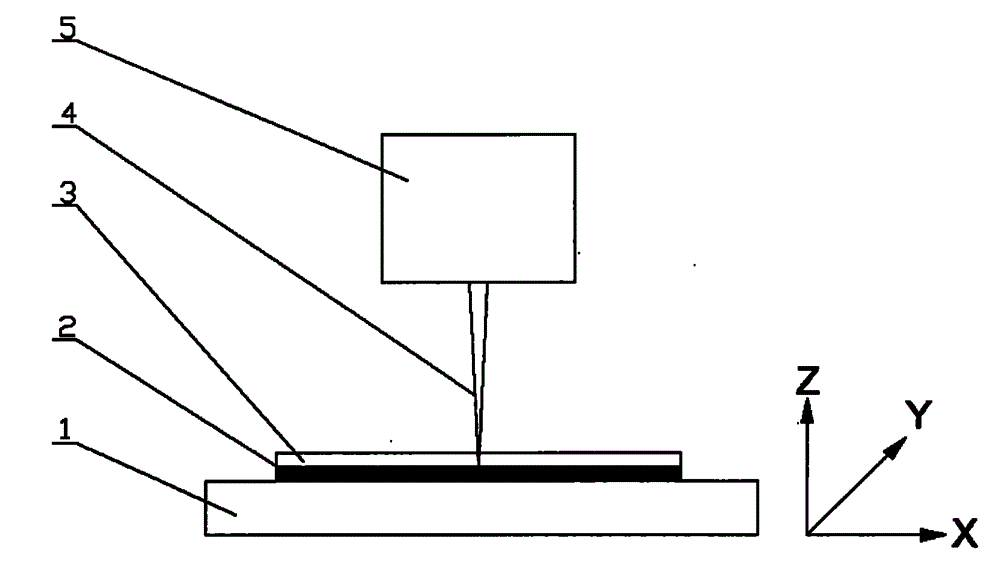

[0016] 1) Horizontally fix the graphite sheet 2 on the workbench 1;

[0017] 2) The glass substrate 3 is fixed on the upper surface of the graphite sheet 2, and the lower surface of the glass substrate 3 is in close contact with the upper surface of the graphite sheet 2;

[0018] 3) The laser beam 4 is irradiated on the interface between the glass substrate 3 and the graphite sheet 2; under the continuous action of the laser beam 4, combined with the worktable 1 on which the workpiece is installed, it moves linearly along the Z direction, and the vibrating mirror 5 moves along the X direction. Scanning in the / Y direction to achieve marking on the glass substrate.

[0019] 4) After the laser marking is completed, the glass substrate 3 is removed, and an appropriate amount of deionized water is added to an ultrasonic cleaner to clean the glass substrate 3 for 3 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com