Manufacturing method for integrated single-cylinder water purifier

A barrel water purifier and a manufacturing method technology are applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., to achieve the effect of sweet water glycol, thorough filtration, and reduced hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

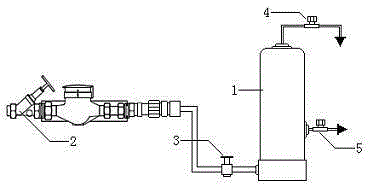

[0012] figure 1 Show the situation of the water treatment device of the present invention, as for urban and rural households and enterprises and institutions use, then directly tap water or self-made tap water is introduced, and send in the device of the present invention through main valve 2 and water inlet valve 3 and carry out filtering treatment , the treated water is exported to the outside through the valve 4 for use.

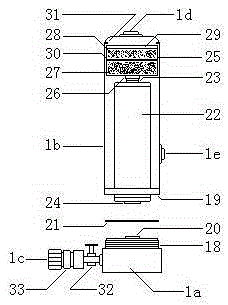

[0013] figure 2 Among them, the filter device 1 is an airtight container composed of a cylinder body 1b and a base 1a, the cylinder body 1b and the base 1a are screwed together, the left side of the base is provided with a water inlet 1c, and the top of the airtight container cylinder is provided with a water outlet 1d, The right side of the airtight container cylinder is provided with a sewage outlet 1e, the base of the airtight container is provided with a spiral outer thread port 18 connected to the cylinder body, the lower opening of the cylinder bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com