A method of producing an amino acid fertilizer based on solid fermentation and enzymolysis of rapeseed meal

A solid fermentation and amino acid technology, applied in the field of microbial fermentation, can solve the problems of losing the advantage of low glucosinolates, wasting rapeseed meal resources, and increasing the content of glucosinolates, so as to increase the content of free amino acids and small peptides, increase the activity of soil microorganisms, and increase protein content. The effect of high degree of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

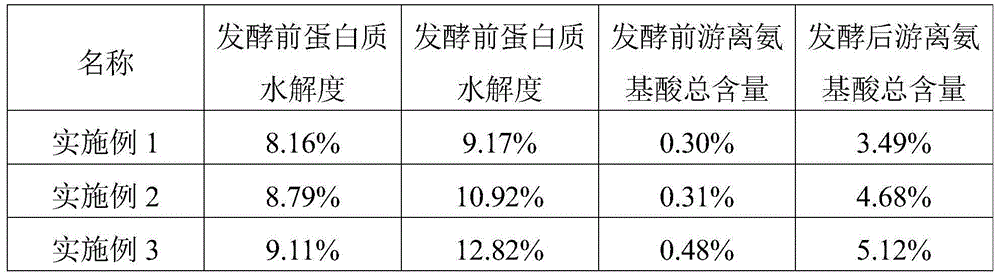

Embodiment 1

[0017] Rapeseed meal, bran, water and lime are mixed and tempered in a weight ratio of 45:20:25:0.1 to prepare a fermented material wet base. Insert Stenotrophomonas maltophilia seed liquid and Bacillus pumilus seed liquid into the fermented material wet base, so that the weight ratio of the three is 100:5:8, and the bacterial liquid of Stenotrophomonas maltophilia and Bacillus pumilus The weight ratio is 3:7, stirred evenly, placed at room temperature, the fermentation period is 96h, the initial pH value of fermentation is 6, turned and thrown 4 times, solid fermentation, enzymatic hydrolysis, and drying to obtain amino acid fertilizer.

Embodiment 2

[0019] Rapeseed meal, bran, water and lime are mixed and tempered in a weight ratio of 48:18:30:0.1 to prepare a fermented material wet base. Insert Stenotrophomonas maltophilia seed liquid and Bacillus pumilus seed liquid into the wet base of fermentation material, so that the weight ratio of the three is 100:6:4, and the bacterial liquid of Stenotrophomonas maltophilia and Bacillus pumilus The weight ratio is 5:3, stirred evenly, placed at room temperature, the fermentation cycle is 120h, the initial pH value of fermentation is 7, turned and thrown 5 times, solid fermentation, enzymatic hydrolysis, and drying to obtain amino acid fertilizer.

Embodiment 3

[0021] Rapeseed meal, bran, water and lime are mixed and tempered in a weight ratio of 50:25:35:0.1 to prepare a fermented material wet base. Insert Stenotrophomonas maltophilia seed liquid and Bacillus pumilus seed liquid into the fermented material wet base, so that the weight ratio of the three is 100:5:5, and the bacterial liquid of Stenotrophomonas maltophilia and Bacillus pumilus The weight ratio is 1:1, stirred evenly, placed at room temperature, the fermentation period is 144h, the initial pH value of fermentation is 9, turned and thrown 6 times, solid fermentation, enzymatic hydrolysis, and drying to obtain amino acid fertilizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com