Preparation method for tetrahydrofurfuryl alcohol

A technology for preparing tetrahydrofurfuryl alcohol and hydrogen, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., can solve problems such as increased cost and product separation difficulty, and reduce reaction costs , the effect of reducing costs and reducing the difficulty of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

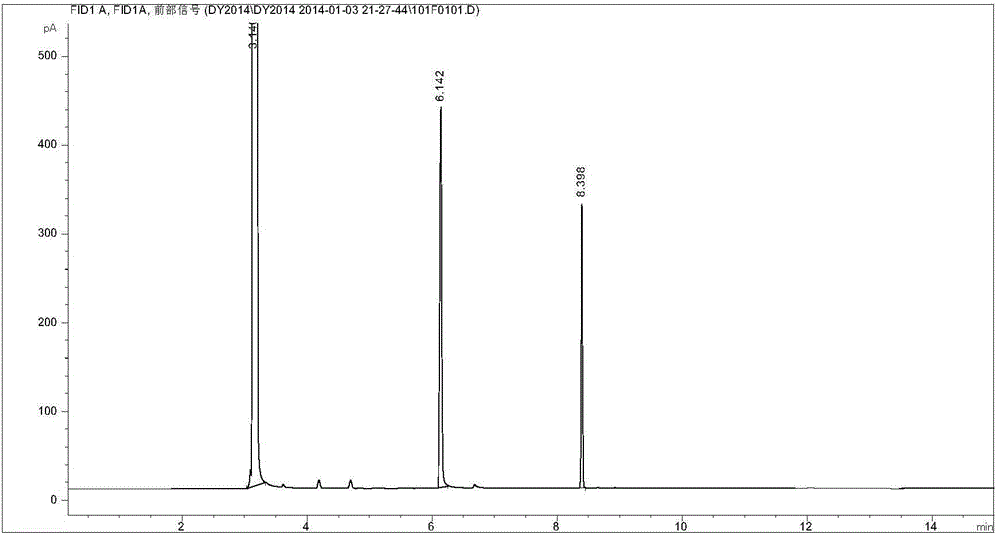

Image

Examples

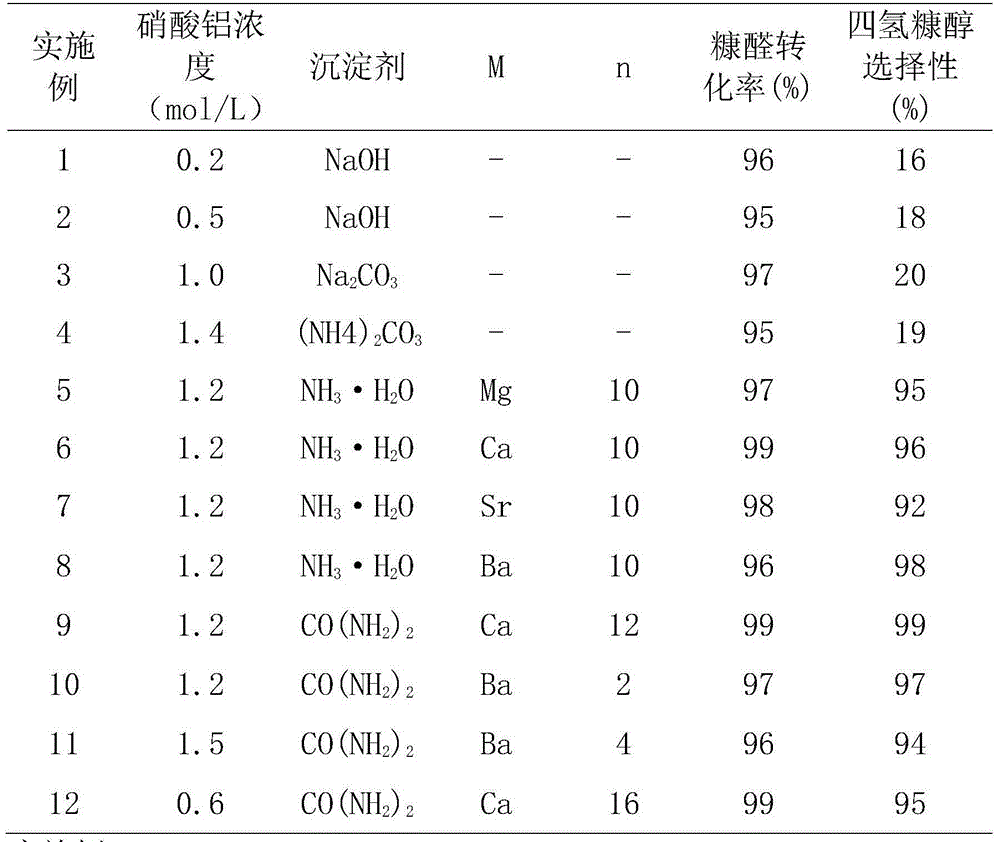

Embodiment 1-12

[0023] Preparation of the carrier:

[0024] Weigh a certain amount of Al(NO 3 ) 3 9H 2 O and M (NO 3 ) 2 (M=Mg, Ca, Sr, Ba) were dissolved in 100 mL of deionized water to keep the M / Al molar ratio at n%. Then dilute to 250 mL with deionized water. Under the condition of stirring, add an aqueous solution of precipitating agent dropwise to the above solution until the pH of the solution is 8-9. Stirring was continued for 4h, and the mixture was allowed to stand at room temperature for 24h. The above precipitate was centrifuged and washed 5 times, and then dried in an oven at 120°C for 12 hours. The dried precipitate was calcined at 600 °C for 6 h in a muffle furnace. get MO-Al 2 o 3 -n support (wherein n% is the molar ratio of M / Al, M=Mg, Ca, Sr, Ba).

[0025] Preparation of Ni supported catalyst

[0026] Weigh a certain amount of Ni(NO 3 ) 2 ·6H 2 O makes the Ni loading amount to 10wt%, adding to deionized water and stirring to dissolve. The alumina support prep...

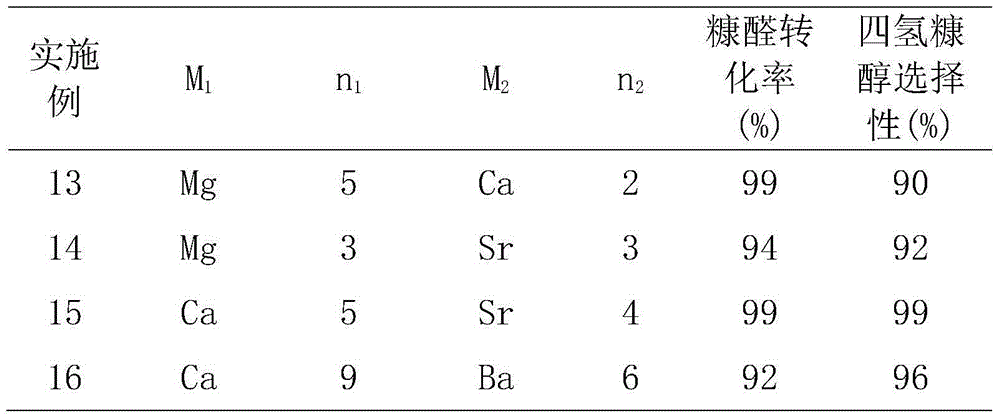

Embodiment 13-17

[0031] Add two kinds of alkaline earth metal nitrate solutions during the preparation of the carrier in Example 3, so that the general structural formula of the prepared catalyst is Ni / M 1 O-M2 O-Al 2 o 3 , where M 1 , M 2 For two different alkaline earth metals, the molar content of both is n 1 % and n 2 %, other conditions are the same as Embodiment 3, and the reaction results are shown in Table 2.

[0032] Table 2 The effect of carrier components on the hydrogenation performance of furfural

[0033]

Embodiment 17-21

[0035] Adjust the nickel nitrate quality and carrier quality in embodiment 9, make the loading of nickel be x%, and change the molar ratio of furfural and Ni to be y;

[0036] Table 3 Effect of catalyst loading and product dosage on furfural hydrogenation performance

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com