Weather-resistant PVC(polyvinyl chloride) film and manufacturing method thereof

A weather-resistant and coating technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of no improvement and change in the properties of PVC films, and achieve the advantages of simple and easy processing methods, cumbersome and complex processes, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of weather-resistant PVC film of the present invention comprises the following steps:

[0024] (1) Deploying coating material: batching according to the parts by weight shown in Table 1, adding each component into ethyl ester or butyl ester respectively, stirring and dissolving; the viscosity of the prepared coating material is 12-16s / 4# Chaen cup;

[0025] (2) Preheating: Preheat the PVC mask with a preheating roller. The preheating temperature in summer is 55-60°C, and the preheating temperature in winter is 65-70°C;

[0026] (3) Printing coating: send the preheated PVC mask into the printing machine for coating coating, the angle of the scraper on the printing machine is set to 45°, and the pressure of the printing pressing rubber roller is 3-6N;

[0027] (4) Drying and cooling: drying the film prepared in step (3) at 50-60°C, and winding the finished product after cooling.

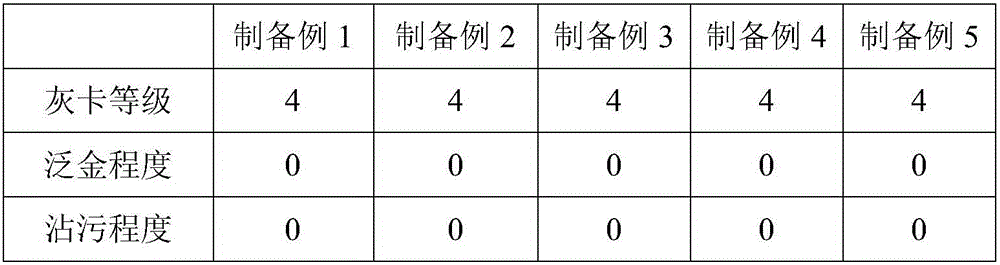

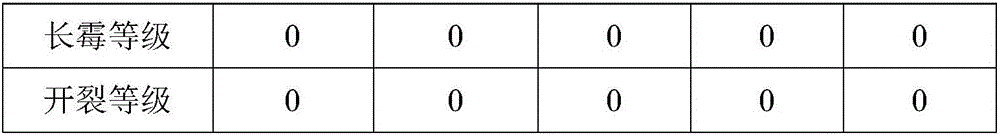

[0028] Table 1 Preparation Example Coating Coating Components

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com