Low-hysteresis rubber composition for journal box rubber springs and preparation method of low-hysteresis rubber composition

The technology of rubber spring and hysteresis glue is applied in the field of low hysteresis rubber compound composition for axle box rubber spring and its preparation field. Low structure and the effect of reducing hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

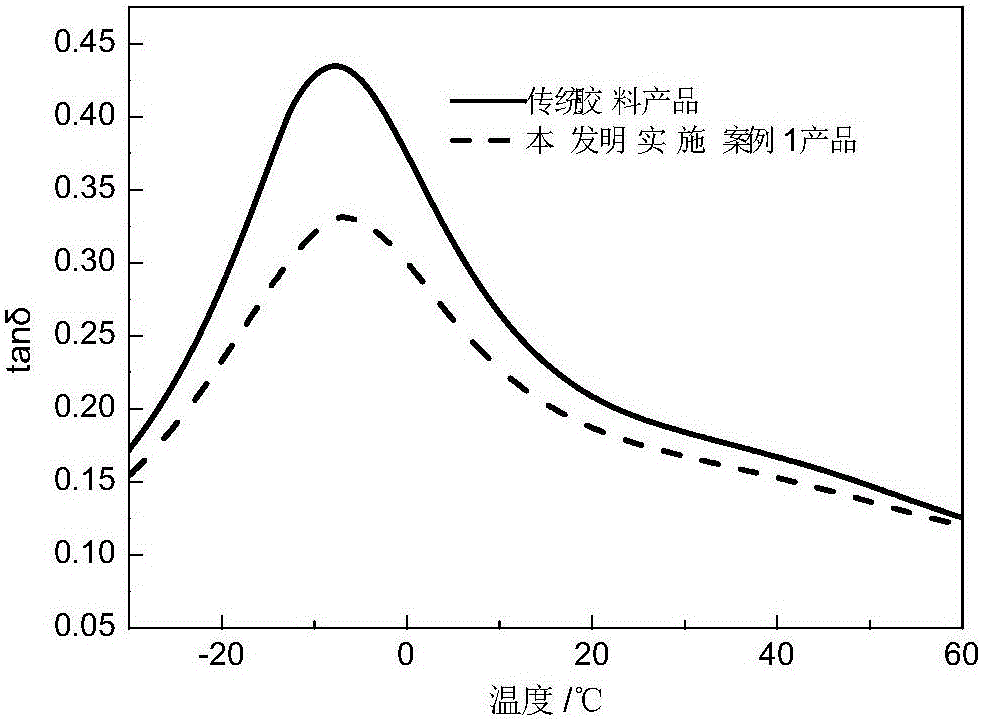

Embodiment 1

[0033] A low-hysteresis compound for an axle box rubber spring, the composition of its main raw materials and the ratio of parts by mass are: 100 parts of deproteinized natural rubber (DPNR); 80 parts of medium particle thermal black N99080 parts; 3 parts of anti-aging agent RD; anti-aging agent 1.5 parts of BLE; 5 parts of zinc oxide; 2 parts of stearic acid; 2.5 parts of sulfur; 1.5 parts of accelerator CBS; 1.5 parts of accelerator NOBS.

[0034] Among them, the particle size of medium particle thermal carbon black is 280nm, the specific surface area of CTAB method is 9m2 / g, and the oil absorption value of DBP is 0.40cm3 / g.

[0035] The rubber material for traditional axle box rubber springs, its main raw material composition and mass ratio are: 100 parts of natural rubber; 35 parts of carbon black N55035 parts; 3-5 parts of aromatic oil; 6-10 parts of anti-aging agent RD; 3-5 parts of anti-aging agent BLE; 3-10 parts of zinc oxide; 1-5 parts of stearic acid; 1-10 parts o...

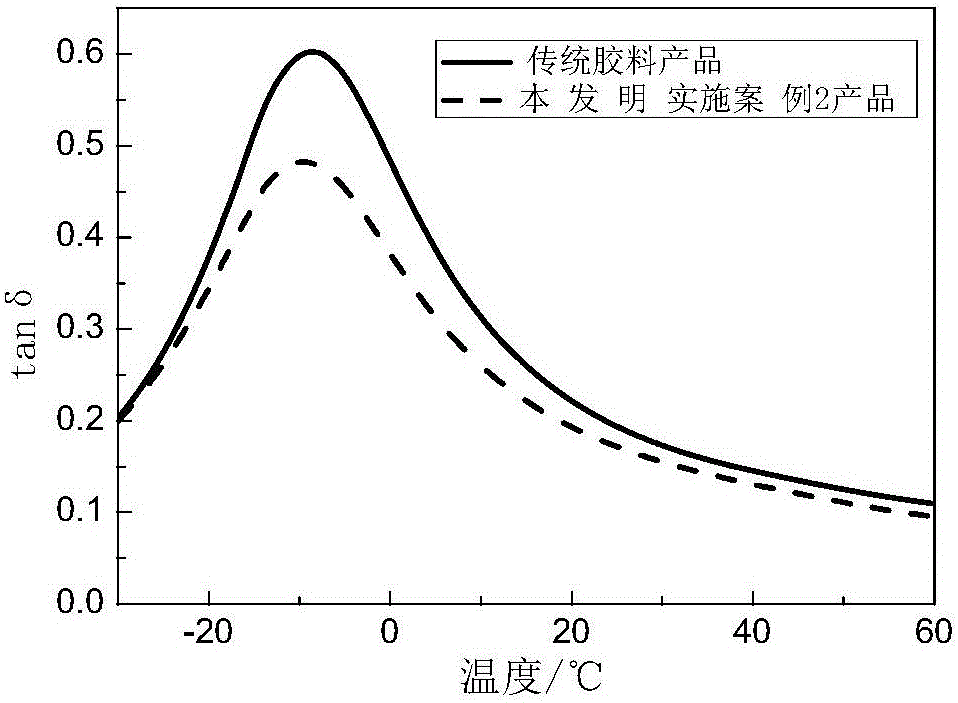

Embodiment 2

[0050] A low-hysteresis rubber compound for axle box rubber springs, the composition and mass ratio of its main raw materials are: 100 parts of deproteinized natural rubber (DPNR); 60 parts of medium-sized thermal cracking carbon black; 2 parts of anti-aging agent RD; 1 part of anti-aging agent BLE ; 3 parts of zinc oxide; 1.2 parts of stearic acid; 1 part of sulfur; 2.3 parts of accelerator CBS; 2.3 parts of accelerator NOBS.

[0051] Among them, the particle size of medium particle thermal carbon black is 280nm, and the specific surface area of CTAB method is 9m 2 / g, DBP oil absorption value is 0.40cm 3 / g.

[0052] The preparation method is as described in Example 1

[0053] Traditional axle box rubber spring compound, its main raw material composition and mass ratio are: 100 parts of natural rubber; 27 parts of carbon black N550; 3-5 parts of aromatic oil; 6-10 parts of anti-aging agent RD; 3-10 parts of zinc; 1-5 parts of stearic acid; 1-10 parts of sulfur; 0.5-3 pa...

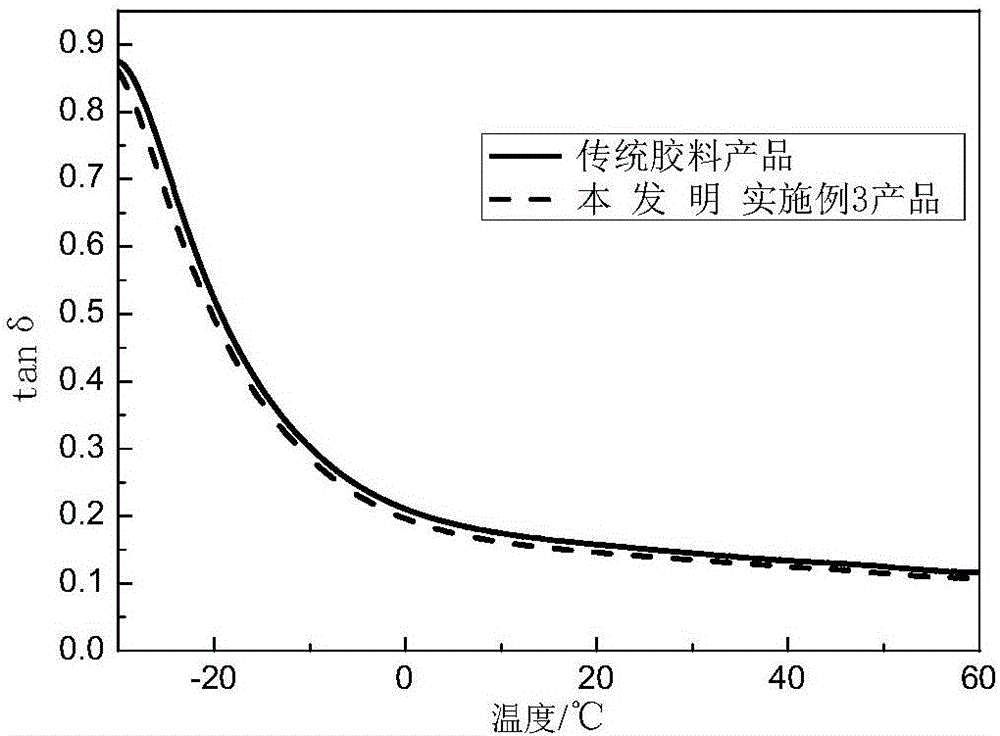

Embodiment 3

[0061] A low-hysteresis rubber compound for axle box rubber springs, the main raw material composition and mass ratio are: 100 parts of deproteinized natural rubber (DPNR); 100 parts of medium particle thermal black; 4 parts of anti-aging agent RD; 2 parts of anti-aging agent BLE 10 parts of zinc oxide; 4 parts of stearic acid; 5 parts of sulfur; 0.5 parts of accelerator CBS; 0.5 parts of accelerator NOBS.

[0062] The preparation method is as described in Example 1

[0063] Traditional axle box rubber spring compound, its main raw material composition and mass ratio are: 100 parts of natural rubber; 45 parts of carbon black N550; 3-5 parts of aromatic oil; 6-10 parts of antioxidant RD; 3-5 parts of antioxidant BLE; 3-10 parts of zinc; 1-5 parts of stearic acid; 1-10 parts of sulfur; 0.5-3 parts of accelerator TMTD; 1-4.5 parts of accelerator NOBS.

[0064] The basic properties of the rubber material of the present invention and the traditional rubber material are compared as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com