Equipment for preparing high-concentration gasified coal slurry

A gasification coal, high-concentration technology, applied in the field of machinery, can solve the problems of affecting the working effect, inconvenient use, high manufacturing cost, and achieve the effects of improved efficiency, uniform atomization effect and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

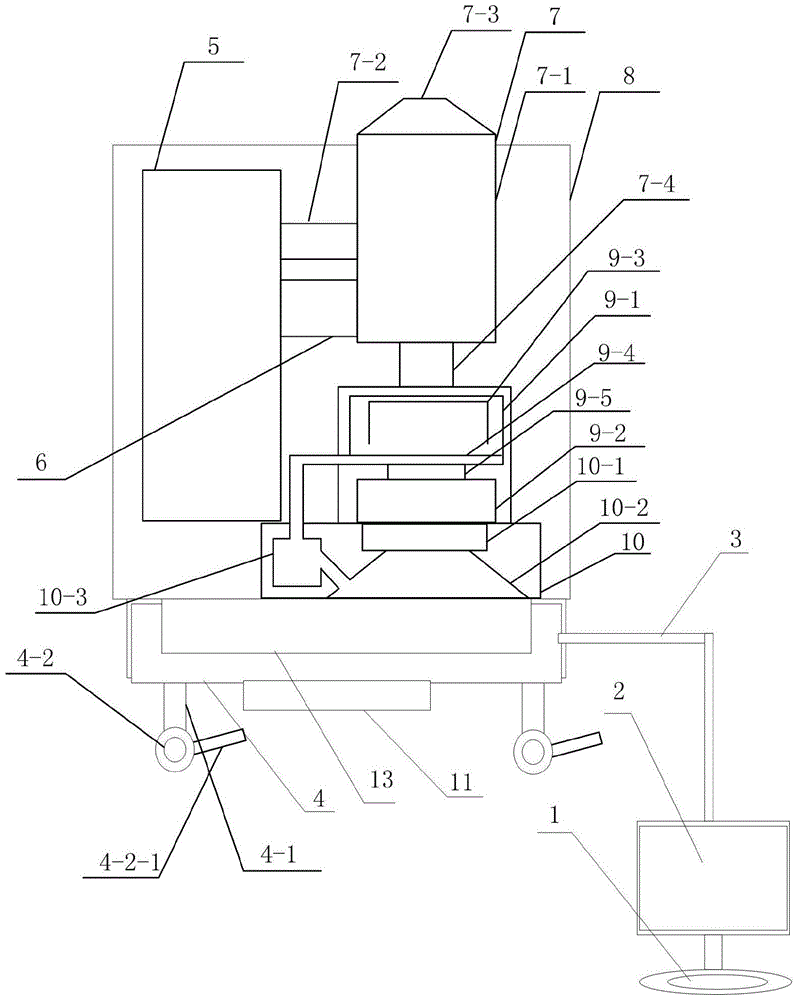

[0035] as shown in the attached picture

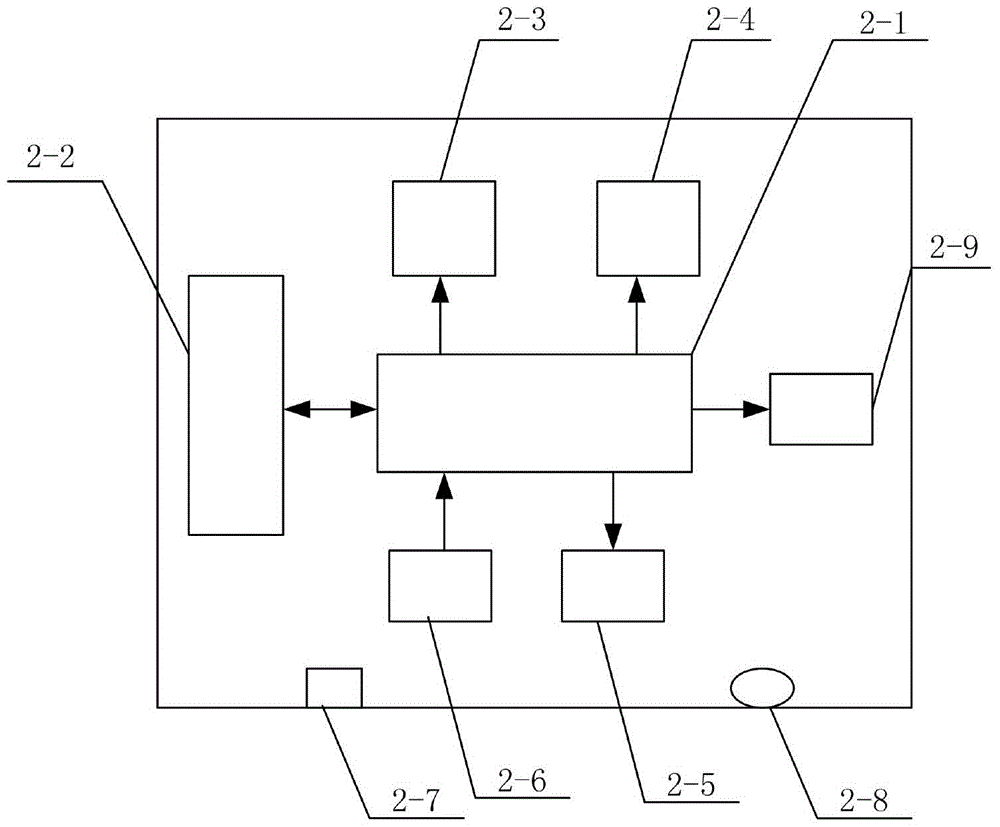

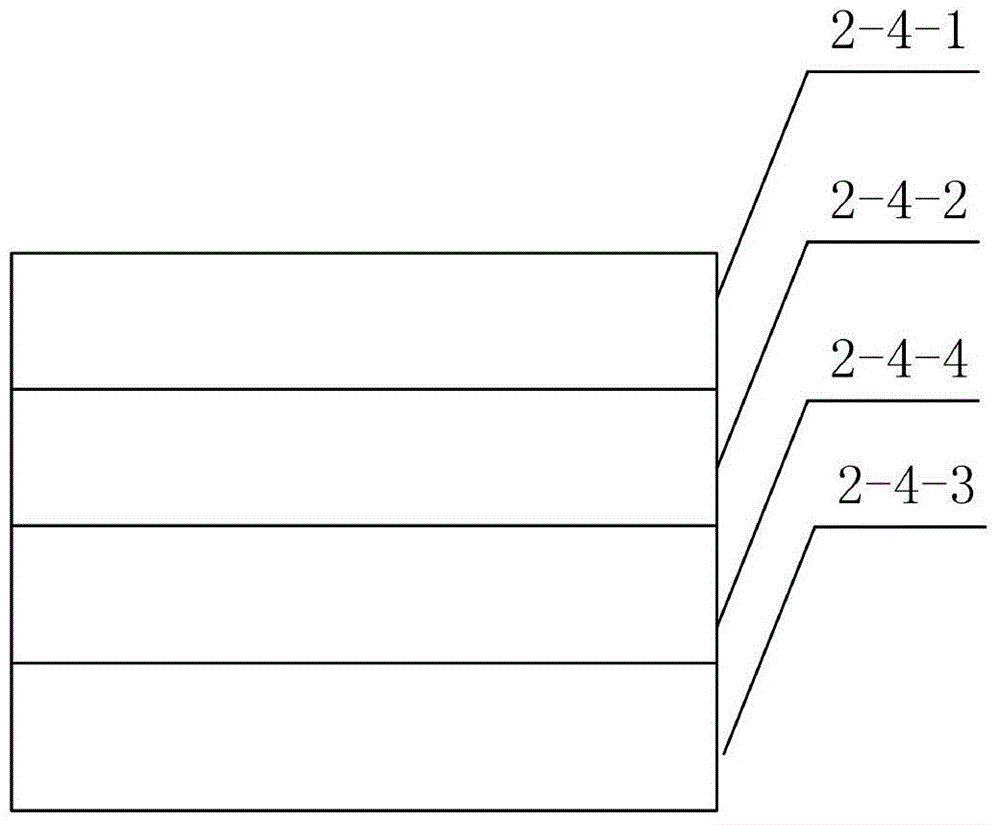

[0036] The present invention provides a device for preparing high-concentration gasified coal slurry. The device for preparing high-concentration gasified coal slurry includes a fixed base 1, a remote electronic control identification device 2, a data transmission line 3, a mobile base device 4, a grinding device 5, Coal slurry pump 6, gasification device 7, protective shell 8, waste heat recovery device 9, washing device 10, power supply device 11, control chip 12 and display screen 13, the fixed base 1 is set on the remote electronic control identification device 2; the grinding device 5, coal slurry pump 6, gasification device 7, protective casing 8, waste heat recovery device 9 and washing device 10 are all arranged on the mobile base device 4, and the power supply device 11 is set at the bottom of the mobile base device 4, the control chip 12 is set inside the mobile base device 4, the grinding device 5 is connected to the gasific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com